Bonding device for leather discharging

A bonding device and leather technology, applied in cleaning devices, transportation and packaging, conveyors, etc., can solve the problems of leather slipping, deviation from the output direction, and hindering the normal operation of the conveyor belt, so as to prevent damage and ensure normal transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

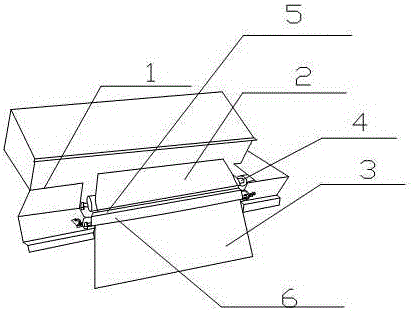

[0018] Such as figure 1 Shown, the present invention comprises heating box 1, upper conveyor belt 2, lower conveyor belt 3 and inclined plate 6. The bottoms of the upper conveyor belt 2 and the lower conveyor belt 3 in this embodiment are both provided with a roller 4 , and both ends of the roller 4 are fixed on the heating box 1 . The end of the upper conveyor belt 2 in this embodiment is close to the lower conveyor belt 3, and a scraper 5 is arranged on the outside of the upper conveyor belt 2. The scraper 5 is close to the slant plate 6 and is located above the slant plate 6. The length of the scraper 5 and the slant plate 6 are of equal length. The swash plate 6 of the present embodiment is arranged on the outside of the drum 4 at the bottom of the conveyor belt 3 at the output.

[0019] A slant plate is set outside the roller at the bottom of the lower conveyor belt at the output, so that the glued leather can be output smoothly and prevent the leather from being damage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com