High-speed intake and vent valve provided with water-hammer-resistant device

A high-speed technology for intake and exhaust valves, applied in the direction of valve devices, valve operation/release devices, valve fluid energy absorption devices, etc., can solve the problems of reduced flow rate, heavy weight, large volume, etc., and achieve volume reduction , prevent water hammer, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

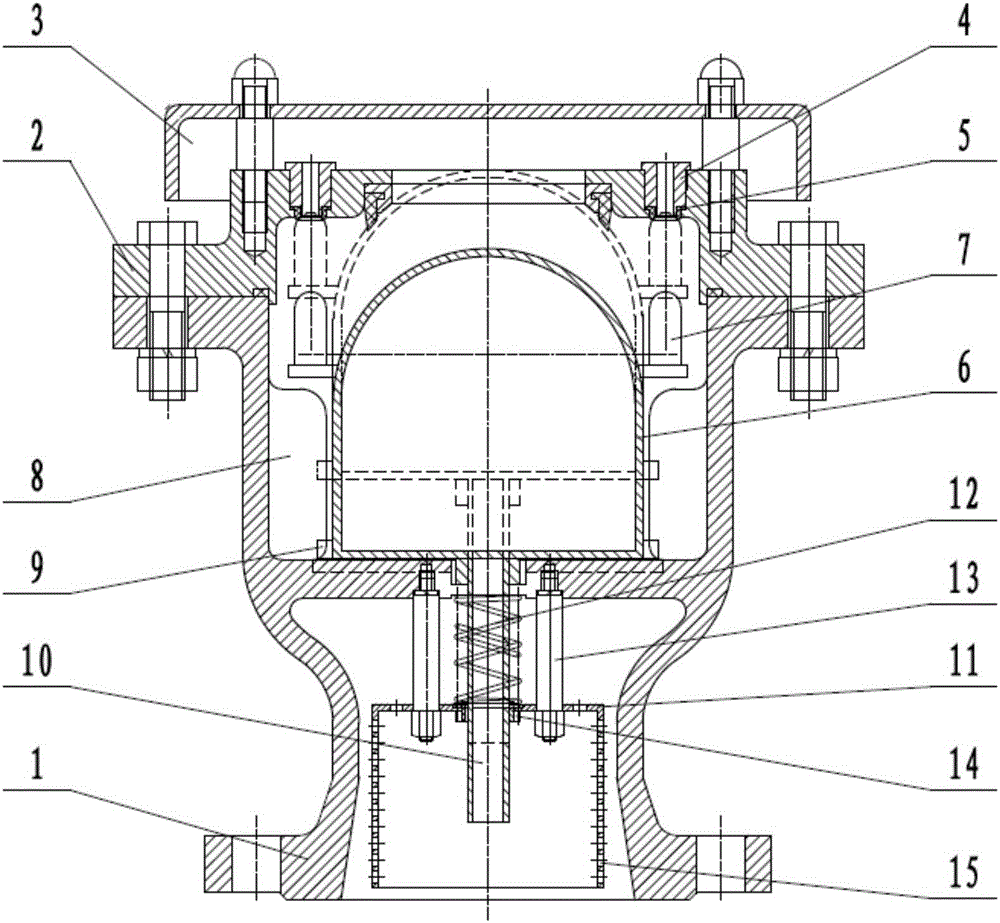

[0017] Such as figure 1 As shown, a high-speed intake and exhaust valve with a built-in anti-hammer device includes a valve body 1, a valve cover 2 is fixed on the top of the valve body 1, and a sealing ring is provided between the valve body 1 and the valve cover 2 , the top of the valve cover 2 is fixed with a gland 3, and the valve cover 2 is provided with multiple groups of micro-exhaust valve seats 4, and the bottom of the micro-exhaust valve seat 4 is provided with a micro-exhaust valve seat sealing ring 5, The valve body 1 includes an upper body cavity and a lower inlet end, a partition is provided between the body cavity and the inlet end, and an anti-hammer spool 11 is arranged inside the inlet end, and the anti-hammer spool 11 The four sides and the upper end surface are provided with a plurality of through holes 15 arranged in an orderly manner. The center of the upper end surface of the waterproof hammer valve core 11 is provided with a buffer spring 12, and the bo...

Embodiment 2

[0022] Such as figure 1 As shown, a high-speed intake and exhaust valve with a built-in anti-hammer device includes a valve body 1, a valve cover 2 is fixed on the top of the valve body 1, and a sealing ring is provided between the valve body 1 and the valve cover 2 , the top of the valve cover 2 is fixed with a gland 3, and the valve cover 2 is provided with multiple groups of micro-exhaust valve seats 4, and the bottom of the micro-exhaust valve seat 4 is provided with a micro-exhaust valve seat sealing ring 5, The valve body 1 includes an upper body cavity and a lower inlet end, a partition is provided between the body cavity and the inlet end, and an anti-hammer spool 11 is arranged inside the inlet end, and the anti-hammer spool 11 The four sides and the upper end surface are provided with a plurality of through holes 15 arranged in an orderly manner. The center of the upper end surface of the waterproof hammer valve core 11 is provided with a buffer spring 12, and the bo...

Embodiment 3

[0027] Such as figure 1 As shown, a high-speed intake and exhaust valve with a built-in anti-hammer device includes a valve body 1, a valve cover 2 is fixed on the top of the valve body 1, and a sealing ring is provided between the valve body 1 and the valve cover 2 , the top of the valve cover 2 is fixed with a gland 3, and the valve cover 2 is provided with multiple groups of micro-exhaust valve seats 4, and the bottom of the micro-exhaust valve seat 4 is provided with a micro-exhaust valve seat sealing ring 5, The valve body 1 includes an upper body cavity and a lower inlet end, a partition is provided between the body cavity and the inlet end, and an anti-hammer spool 11 is arranged inside the inlet end, and the anti-hammer spool 11 The four sides and the upper end surface are provided with a plurality of through holes 15 arranged in an orderly manner. The center of the upper end surface of the waterproof hammer valve core 11 is provided with a buffer spring 12, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com