Bearing and locking device firm in connection

A technology of locking device and load device, applied in the direction of fixing device, supporting machine, engine frame, etc., can solve problems such as bolt corrosion and inconvenient operation, and achieve the effect of improving stress condition, enhancing structural stability, and avoiding loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

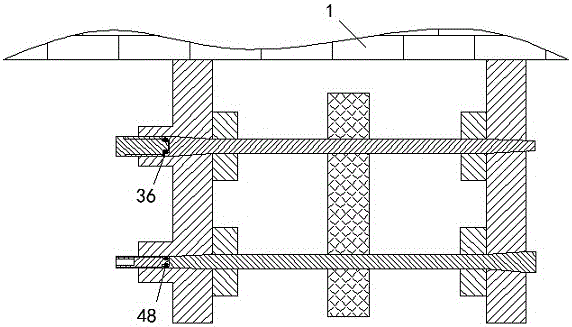

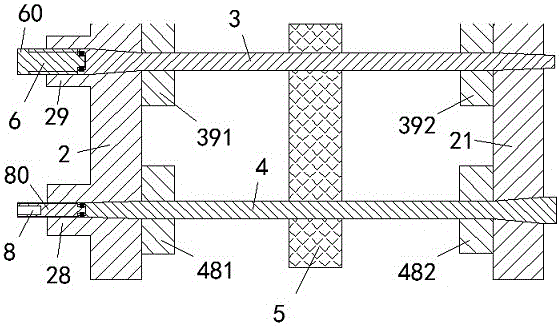

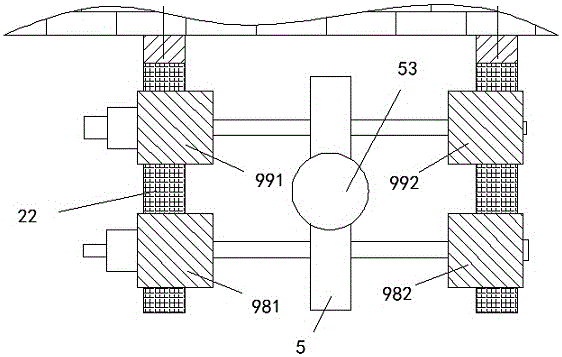

[0012] Combine below Figure 1-6 The present invention will be described in detail.

[0013] According to the embodiment of the present invention, the firmly connected bearing locking device is used to carry the load device and lock the loaded load device, including the left bracket 2 and the right bracket 21 for separately fastening on the base 1 and their respective Both pass through the rear locking rod 3 and the front locking rod 4 of the left bracket 2 and the right bracket 21, wherein the rear locking rod 3 includes a rear rod main body and is connected to the left end of the rear rod main body through a rear thrust bearing 36. To the fixedly connected pushing stud member 6, the front locking rod 4 includes a front rod main body and a pull screw sleeve 8 axially fixedly connected to the left end of the front rod main body through a front thrust bearing 48, wherein , the outer circumferences of the push-off stud member 6 and the pull-screw set 8 are provided with externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com