Spiral pipe steam generator

A technology of a steam generator and a spiral tube, which is applied in the directions of steam generation, steam generation device, steam generation method, etc., can solve the problems of long heating time, large energy consumption, low efficiency, etc., and achieves low water consumption, reduced energy consumption, produce fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

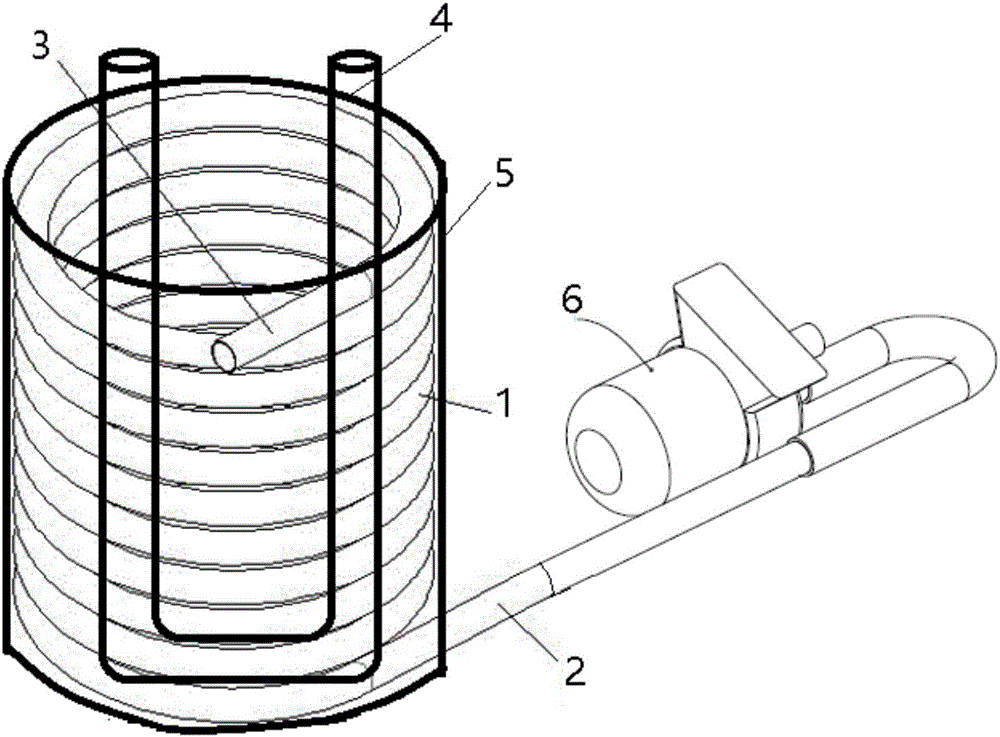

[0027] Such as figure 1 As shown, a spiral tube steam generator includes a heating element U-shaped tube 4, a spiral tube 1, and a water pump 6; wherein, the water pump 6 communicates with the water inlet 2 at one end of the spiral tube, and the other end of the spiral tube is a steam outlet 3 ; The U-shaped tube 4 of the heating assembly is located in the spiral ring of the spiral tube 1, and the outer periphery of the spiral tube 1 is also provided with a heat-preserving layer 5 .

[0028] Further, the steam outlet 3 is connected to the steam inlet nozzle on the side wall of the steam pot, and high-temperature steam can be fed in from the side wall of the steam pot. Example 2

Embodiment 2

[0029] Such as figure 1 and 2 As shown, a helical tube steam generator, a helical tube steam generator, includes a heating element U-shaped tube 4, a helical tube 1, and a water pump; wherein, the water pump communicates with the water inlet 2 at one end of the helical tube, and the other end of the helical tube One end is a steam outlet 3 ; the U-shaped tube 4 of the heating element is located in the spiral ring of the spiral tube 1 , and a heat-preserving layer 5 is provided on the periphery of the spiral tube 1 .

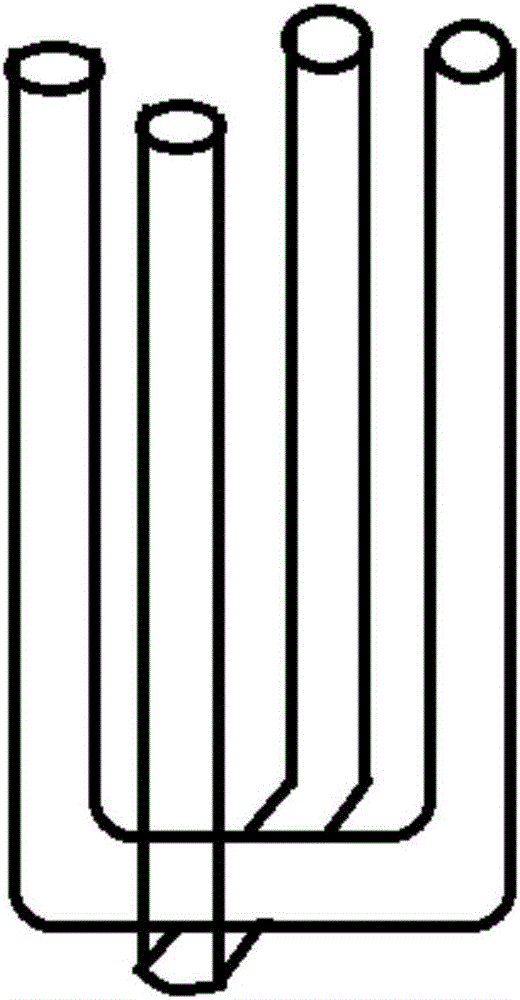

[0030] Such as figure 2 As shown, preferably, there are two U-shaped tubes, which are arranged crosswise.

Embodiment 3

[0032] Such as figure 1 As shown, a spiral tube steam generator includes a heating element U-shaped tube 4, a spiral tube 1, and a water pump 6; wherein, the water pump 6 communicates with the water inlet 2 at one end of the spiral tube, and the other end of the spiral tube is a steam outlet 3 ; The U-shaped tube 4 of the heating assembly is located in the spiral ring of the spiral tube 1, and the outer periphery of the spiral tube 1 is also provided with a heat-preserving layer 5 .

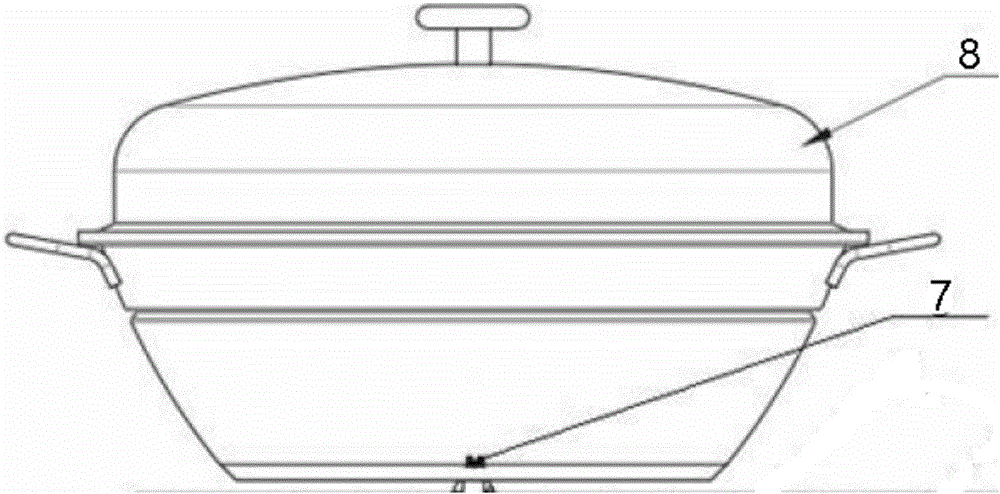

[0033] Such as image 3 As shown, the steam outlet 3 is connected to the steam inlet nozzle 7 at the bottom of the steam pot, and high-temperature steam can be fed from the bottom of the steam pot, and also includes a pot cover 8 for cooking food.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com