Electric heat tracing liquid level meter with RS485 monitoring function

A RS485, electric heat tracing technology, applied in the field of liquid level gauge, can solve the problems of not being able to know the liquid level of field equipment in real time, difficult to ensure safe and reliable operation of production, and not having monitoring functions, etc., to achieve flexible and convenient control methods and stable performance. Reliable and guaranteed to work properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

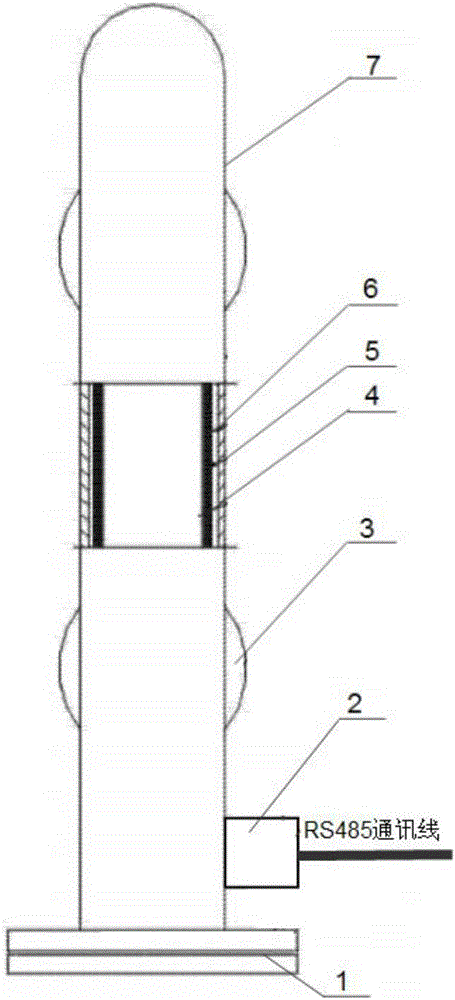

[0017] An electric heating liquid level gauge with RS485 monitoring function, such as figure 1 As shown, it includes a sealing flange 1, an electric control device 2, a connecting flange 3, a measuring cylinder 4, an electric heating belt 5, an insulating layer 6 and a protective shell 7, and the sealing flange is installed at the bottom of the protective shell, and the The measuring cylinder, electric heating band, and insulation layer are installed in the protective shell from the inside to the outside in sequence. The connecting flange and the electric control device are installed on the protective shell. work under the control of the device. In this embodiment, the protective shell is made of protective aluminum skin, and the electric heating belt can be a self-limiting heating heating belt, or an ordinary heating heating belt.

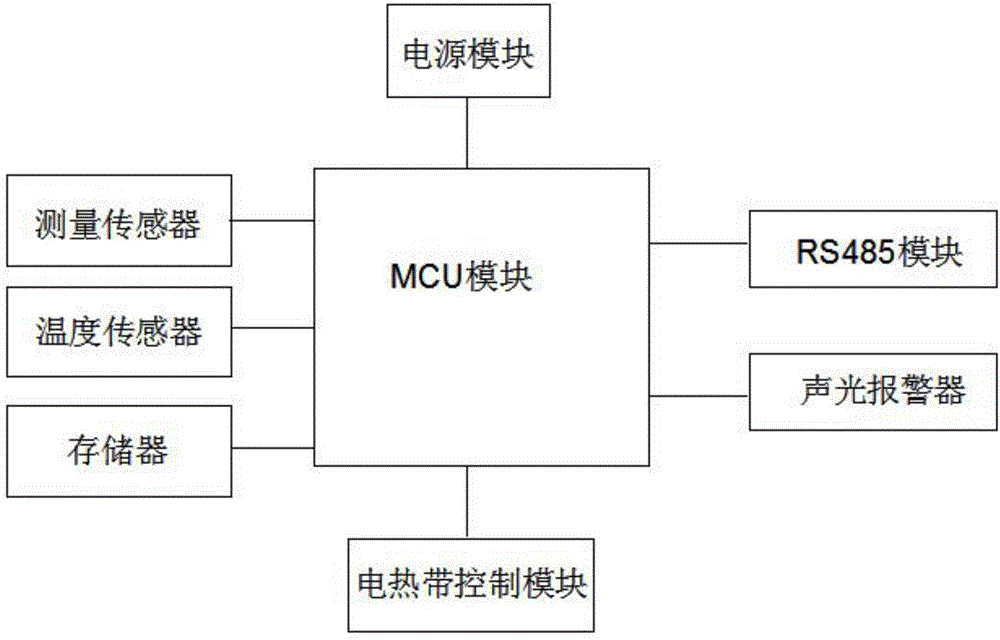

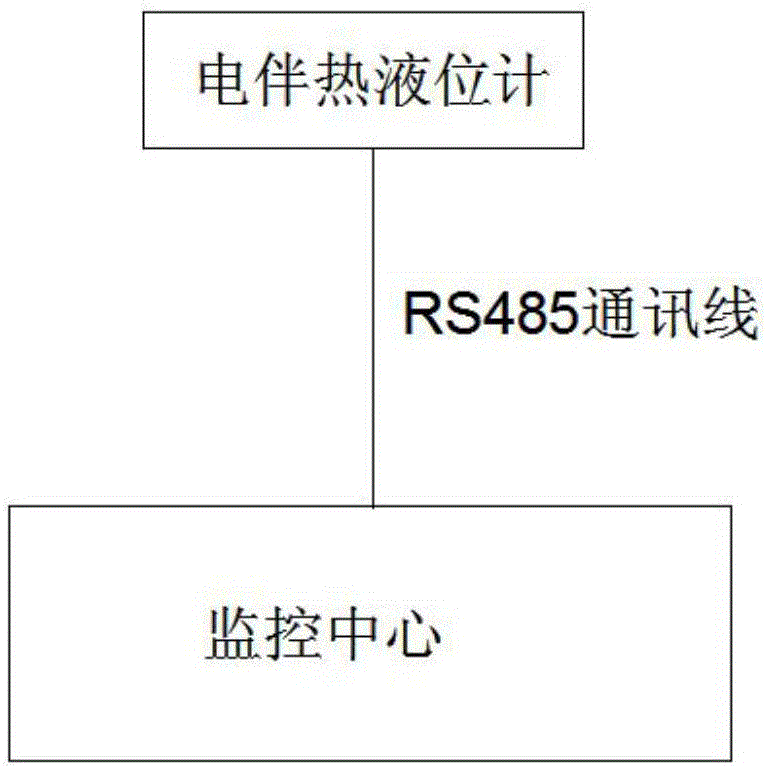

[0018] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com