Carbon black and rubber composition

A technology of rubber composition and carbon black, applied in fibrous fillers, tire parts, transportation and packaging, etc., can solve the problem of low heat generation and achieve the effect of improving reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

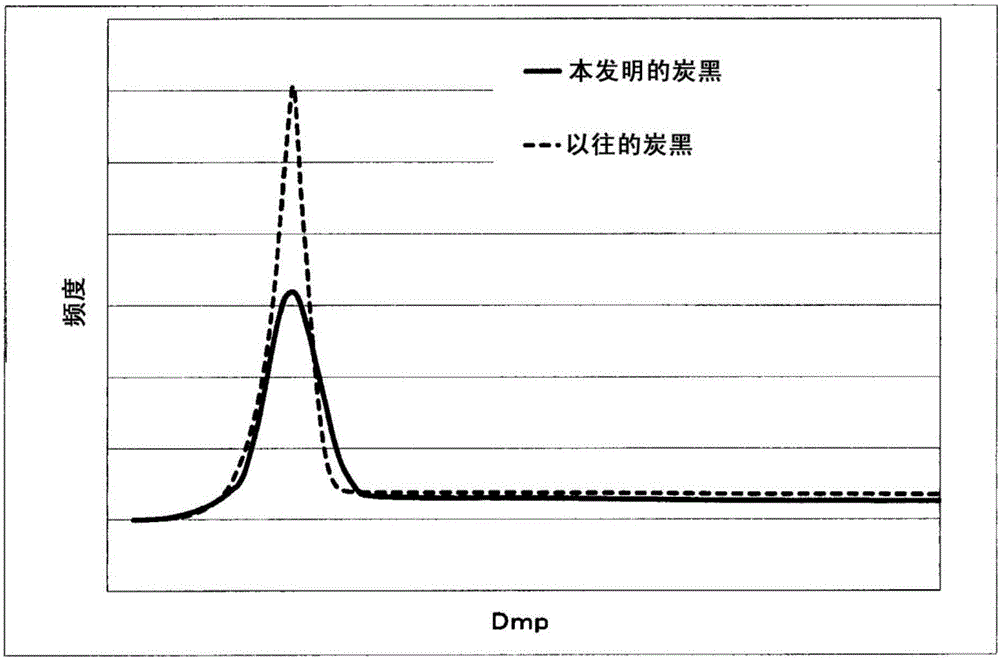

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

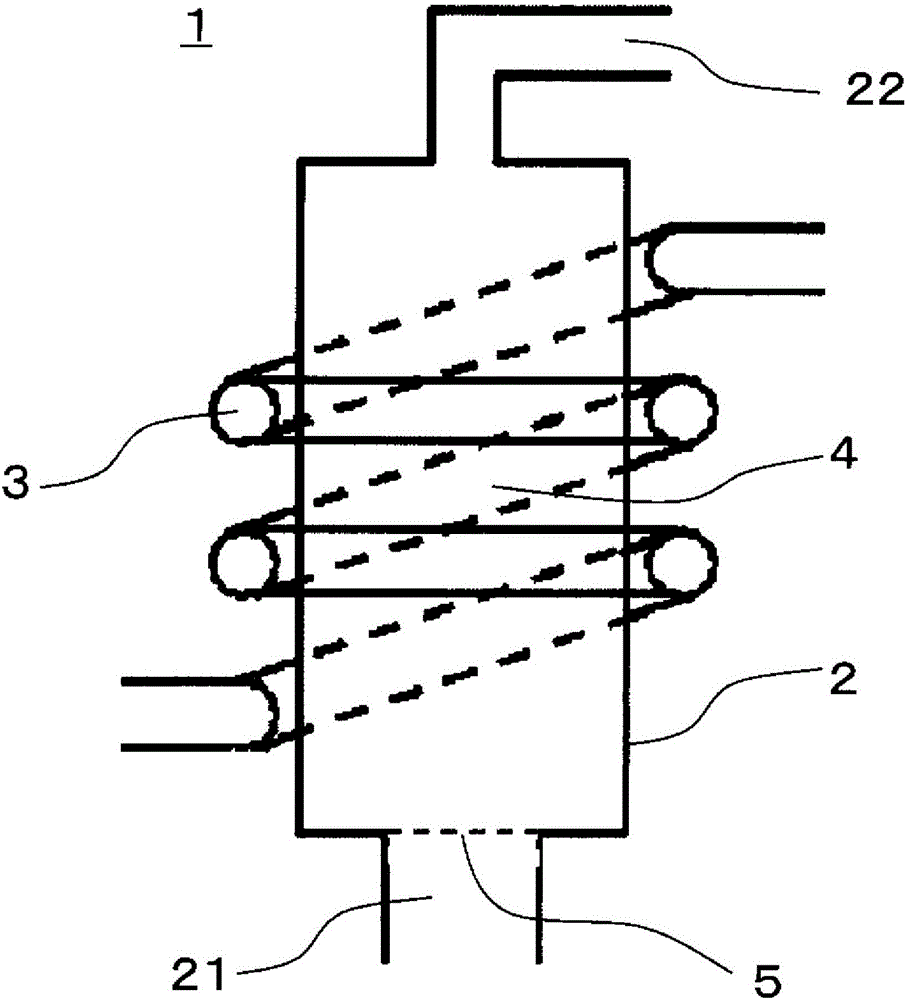

[0090] use figure 2 The shown fluidized bed reaction furnace 1 having a substantially cylindrical shape with a furnace axis extending in a vertical direction was used to produce carbon black.

[0091] figure 2 The casing of the fluidized bed reactor 1 shown is made of SUS304, and the inner wall is made of mullite. The reactor main body 2 constituting the fluidized bed reactor 1 has a gas inlet 21 ( Inner diameter 50mm), there is exhaust port 22 (inner diameter 30mm) at the top of reaction furnace main body 2 simultaneously. Additionally, if figure 2 As shown, the fluidized bed reactor 1 has a heating coil 3 formed by helically winding an electric heating wire on the entire furnace wall outer peripheral surface of the reactor main body 2, and has a stirring area 4 (inner diameter 100mm, Height 200mm) heating structure.

[0092] Moreover, the filter 5 made from SUS was installed in the connection part of the reaction furnace main body 2 and the gas introduction port 21 (s...

Embodiment 2~ Embodiment 6

[0096] For raw carbon black 1 in embodiment 1, change to raw carbon black 2 in embodiment 2 (nitrogen adsorption specific surface area is 120m 2 / g, DBP absorption is the carbon black of 110ml / 100g), in embodiment 3, change to raw material carbon black 3 (nitrogen adsorption specific surface area is 101m 2 / g, DBP absorption is the carbon black of 90ml / 100g), in embodiment 4, change to raw material carbon black 4 (nitrogen adsorption specific surface area is 75m 2 / g, DBP absorption of 99ml / 100g of carbon black), raw material carbon black 5 (nitrogen adsorption specific surface area of 70m 2 / g, carbon black with DBP absorption of 89ml / 100g), raw material carbon black 6 (nitrogen adsorption specific surface area is 71m 2 / g, DBP absorption amount is 84ml / 100g of carbon black), and by processing in the same manner as in Example 1, each of Carbon Black 2 to Carbon Black 6 was obtained.

[0097] The obtained carbon black 2-carbon black 6 nitrogen adsorption specific surface a...

Embodiment 7~ Embodiment 10

[0108] Change the feed rate of hydrocarbon gas in Example 1 to: 6.7 Nm in Example 7 3 / h, embodiment 8 is 7.5Nm 3 / h, embodiment 9 is 8.0Nm 3 Be 8.2Nm in / h, embodiment 10 3 / h, and other than that, by performing the same treatment as in Example 1, each of Carbon Black 7 to Carbon Black 10 was obtained.

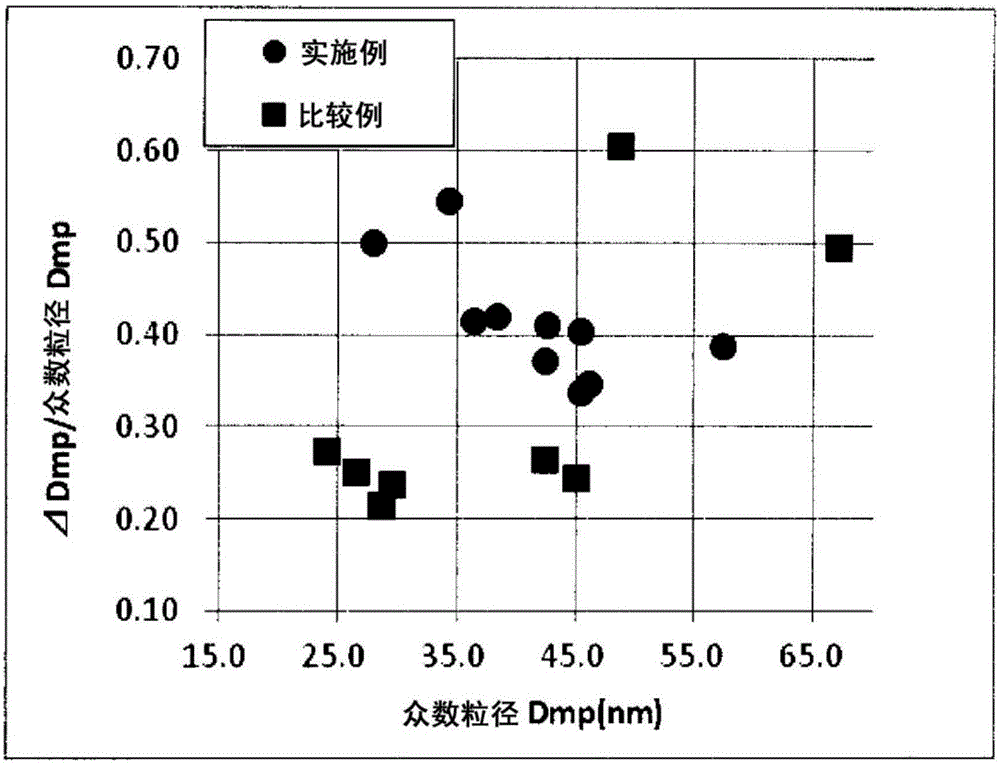

[0109] The obtained carbon black 7-carbon black 10 nitrogen adsorption specific surface area, DBP absorption, aggregate pore mode particle size Dmp, aggregate pore size distribution half-value width ΔDmp and according to the above-mentioned aggregate pore mode particle size Dmp and Table 3 shows ΔDmp / mode particle diameter Dmp defined by the half-value width ΔDmp of the aggregate pore size distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap