Camshaft-adjusting device

A technology of camshaft adjustment and regulator, which is applied to valve devices, engine components, machines/engines, etc., and can solve problems such as the rotor not being locked on one side, high cost, and noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

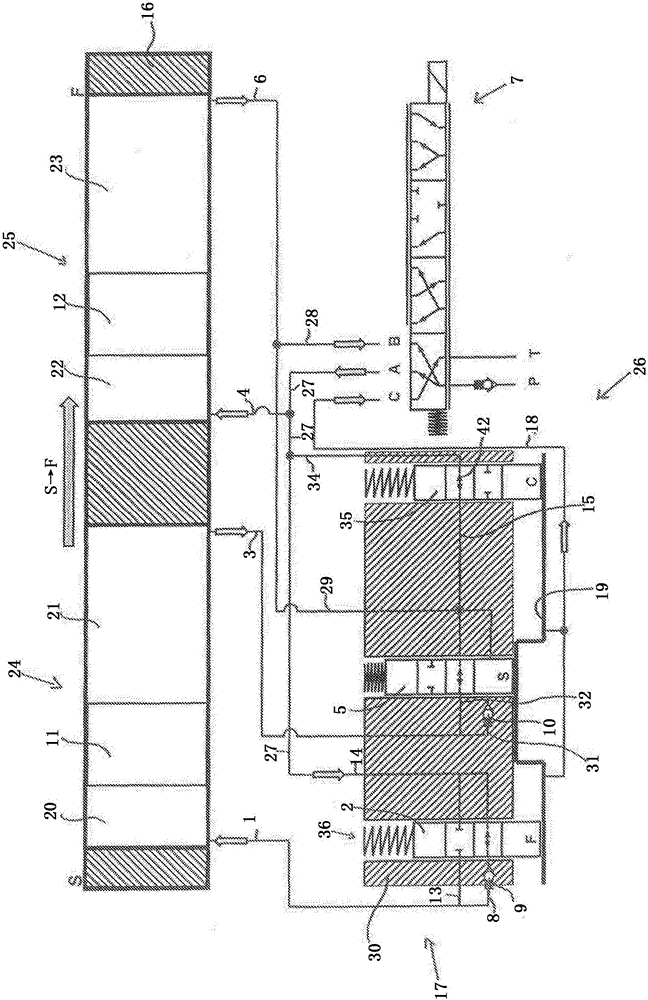

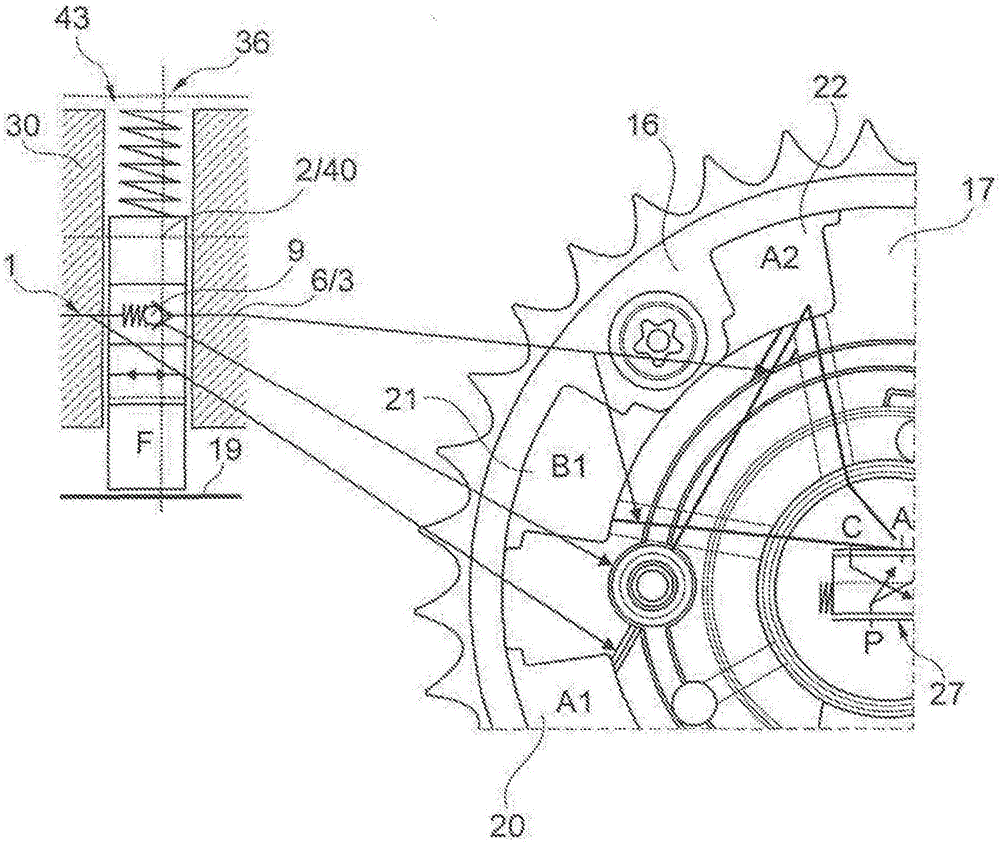

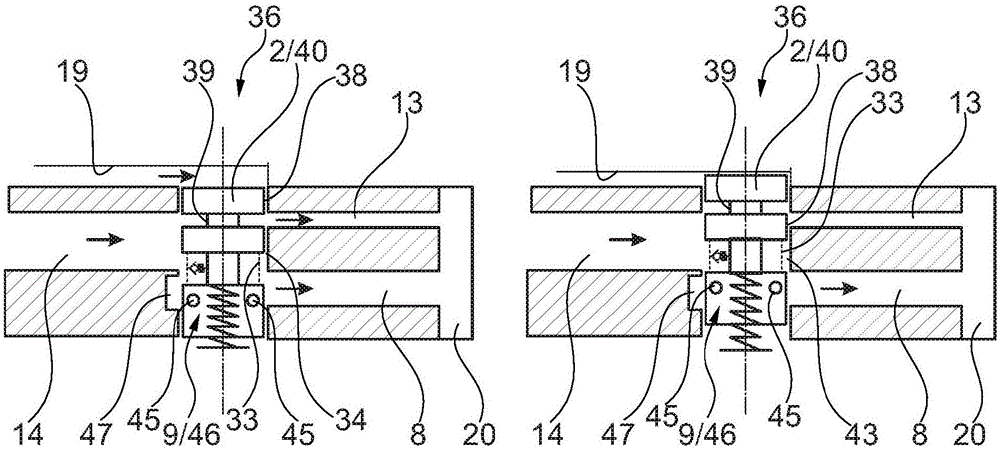

[0026] exist figure 1A camshaft adjusting device with a known basic structure can be seen in the figure, with a schematically shown vane chamber adjuster as a basic component, which comprises a stator 16 that can be driven by a crankshaft, not shown, and that can A rotor 17 , which is connected in a rotationally fixed manner to a camshaft, likewise not shown, has a plurality of vanes 11 and 12 extending radially outward from it. In the upper representation the vane chamber regulator can be seen unfolded, and at the bottom left schematically a section of the rotor 17 with the central locking device 26 can be seen, and at the bottom right the form can be seen schematically. is a switching device for controlling the pressure medium flow of the multi-way switching valve 7 . The multi-way switching valve 7 has an A port, a B port and a C port, to which the pressure medium lines 18 , 27 and 28 are fluidically connected. Furthermore, the multi-way switching valve 7 is fluidically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com