Safety shoe compression-resistant and piercing-resistant performance inspection device

An inspection device and puncture-resistant technology, which is applied to the measurement device of feet or shoe lasts, measurement devices, footwear, etc., can solve the problem of inflexible rotation of screw sleeve and screw, immobility of worm gear and worm, and increased error of test force and other problems, to achieve the effect of easy automatic control operation, easy stepless speed change, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

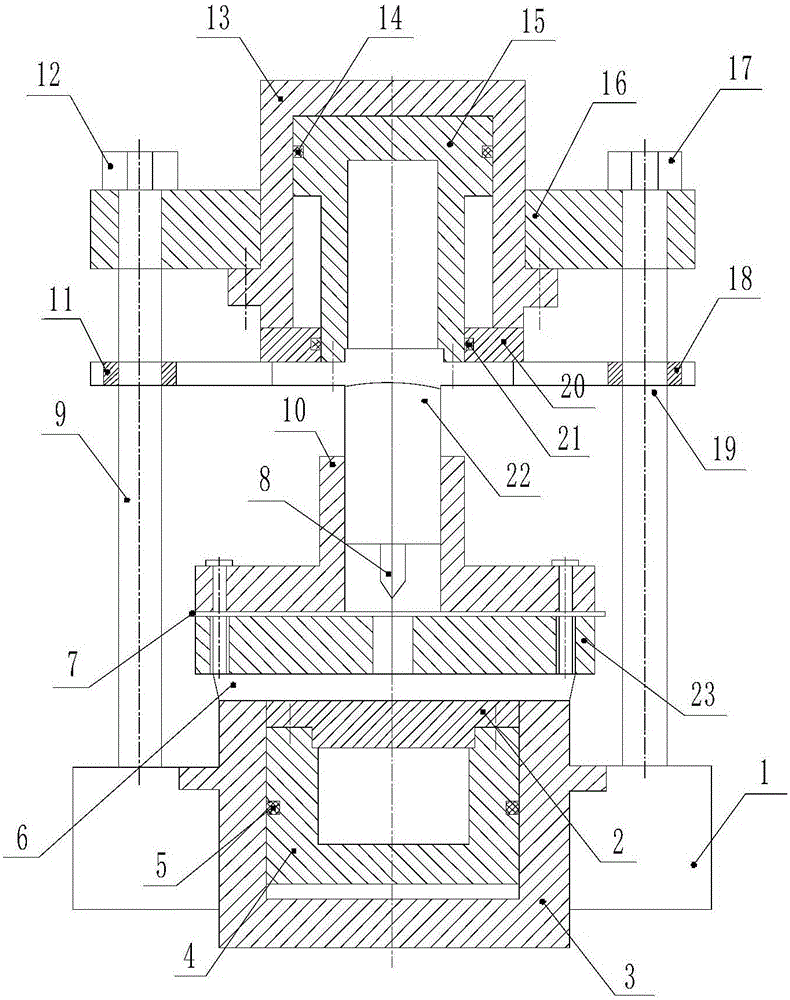

[0017] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0018] A test device for compression resistance and puncture resistance of safety shoes, including: machine base 1, adapter plate 2, main oil cylinder 3, main piston 4, first sealing ring 5, workbench 6, sample 7, thorns 8 , left guide column 9, upper module 10, left guide sleeve 11, left lock nut 12, lift cylinder 13, second sealing ring 14, lift piston 15, beam 16, right lock nut 17, right guide sleeve 18, right Guide column 19, lifting cylinder head 20, third sealing ring 21, pressure head 22 and lower module 23, the main cylinder 3 is installed on the base 1 through a two-dimensional motion platform, and the main piston 4 is installed on the main A first sealing ring 5 is installed in the oil cylinder 3 and between the main piston 4 and the main oil cylinder 3, the adapter plate 2 is fixedly installed on the top surface of the main piston 4 by scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com