Dish washing robot

A robot and dishwashing technology, applied in the field of robotics, can solve problems such as low work efficiency and unacceptable costs for operators, and achieve the effects of labor saving, simplified functions, and high overall integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

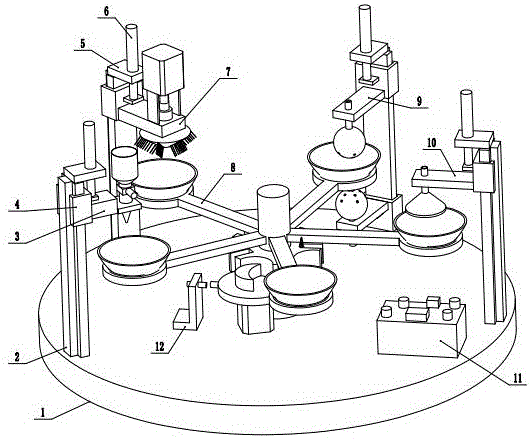

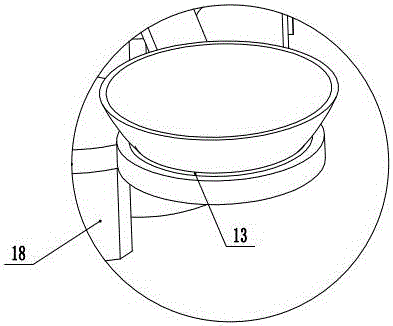

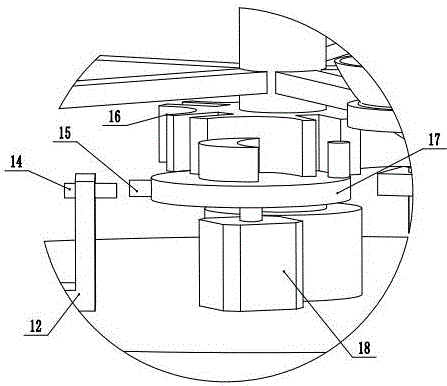

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, a dishwasher robot includes a base 1, four lifting slide rails 2 and four module installation sliders 4, four installation plates 5 and four electric cylinders 6, and a detergent extrusion station working module 3. Scrubbing station working module 7, washing station working module 9, drying and disinfection station working module 10, a bowl rack 8, five rubber pads 13, a control panel 11, a sensor seat 12, a receiving Sensor 14, a sending sensor, a sheave 16, a pin disc 17 and a first stepping motor 18; there is a boss processing a vertically downward through hole in the middle of the base 1; Four lifting slide rails 2 are vertically placed and installed, wherein the second, third and fourth ones in clockwise order are separated from the first one by 72 degrees; There is a T-shaped slot on the side, and a boss connected to the electric cylinder 6 is provided on the insid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap