A single shaft shredder

A shredder, single-shaft technology, used in grain processing and other directions, can solve the problems of easy overheating of the cutter shaft and movable knife, insufficient cutting force, and high energy consumption of the cutter roller, so as to reduce temperature, large cutting force, and energy consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

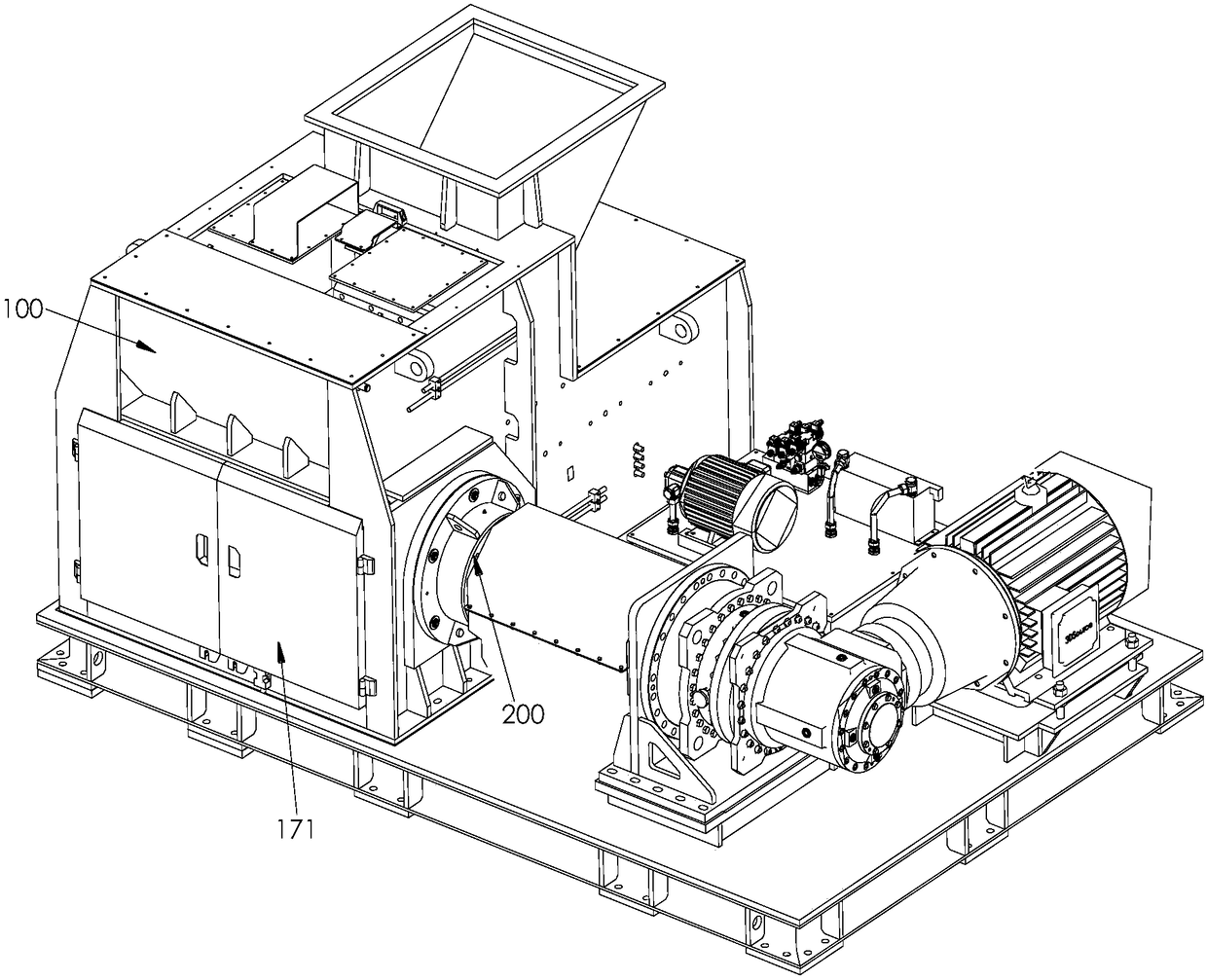

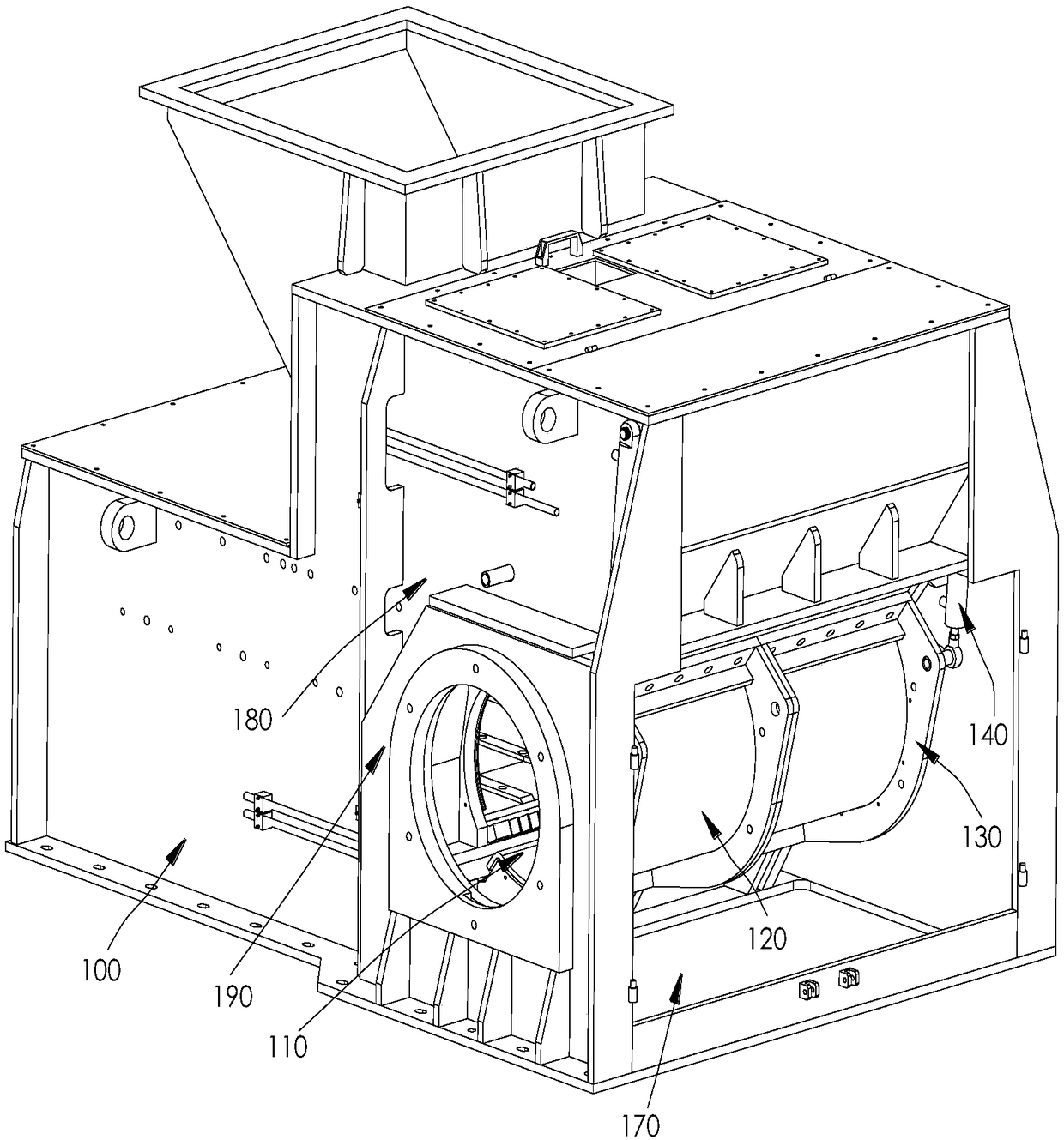

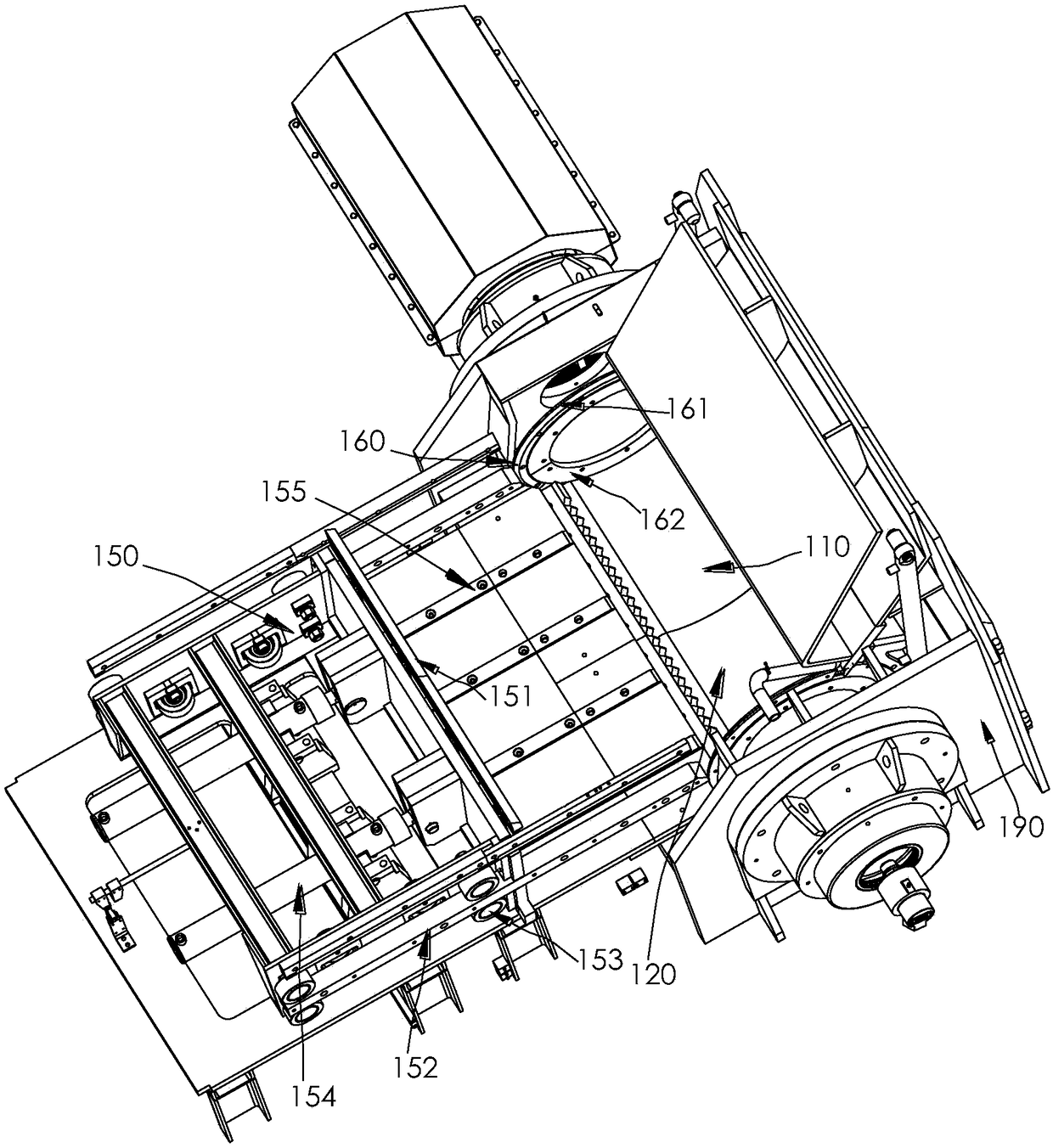

[0032] Such as Figure 1-9 The single-shaft shredder shown includes a box body 100, a pushing mechanism 150, a knife shaft 210, a plurality of moving knives 220 and a fixed knife 230, and a crushing cavity 110 is formed at one end of the box body 100, and the pushing mechanism 150 is located at the end of the box body 100 away from the crushing chamber 110, and the above-mentioned cutter shaft 210 is pivotally connected in the crushing chamber 110, and a water cooling chamber 213 is formed inside the cutter shaft 210, and a plurality of In the first installation slot, a plurality of movable knives 220 can be installed in the plurality of first installation slots in a one-to-one correspondence. The fixed knife 230 is fixed on one side of the crushing cavity 110 and is located on the side of the crushing cavity 110 close to the pushing mechanism 150 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com