Fluid injection area light source indicating and positioning device

A technology of fluid injection and positioning device, applied in the direction of injection device, etc., can solve the problem of difficulty in accurately monitoring the cooling medium injection area, etc., and achieve the effect of precise control and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

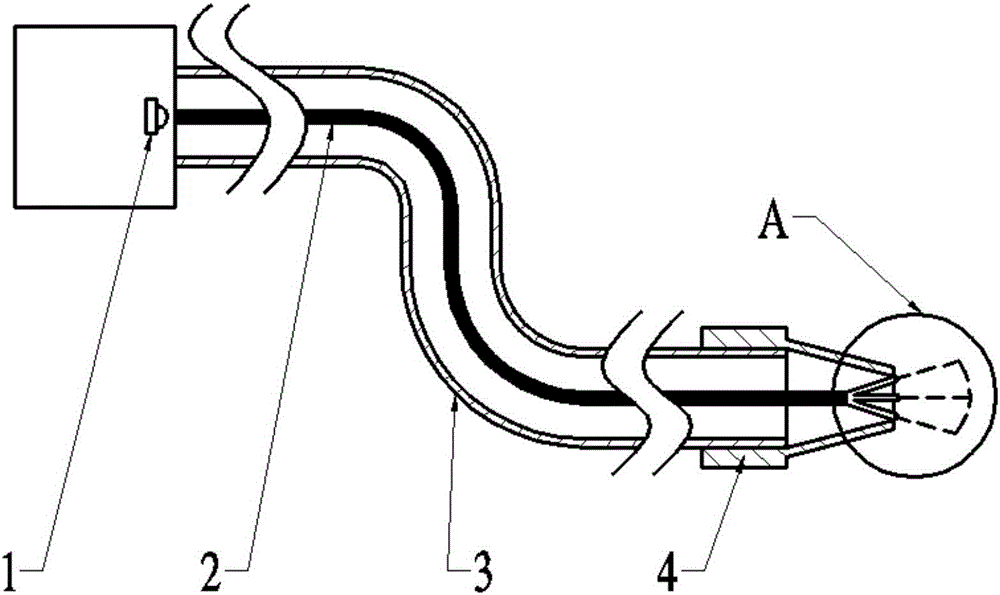

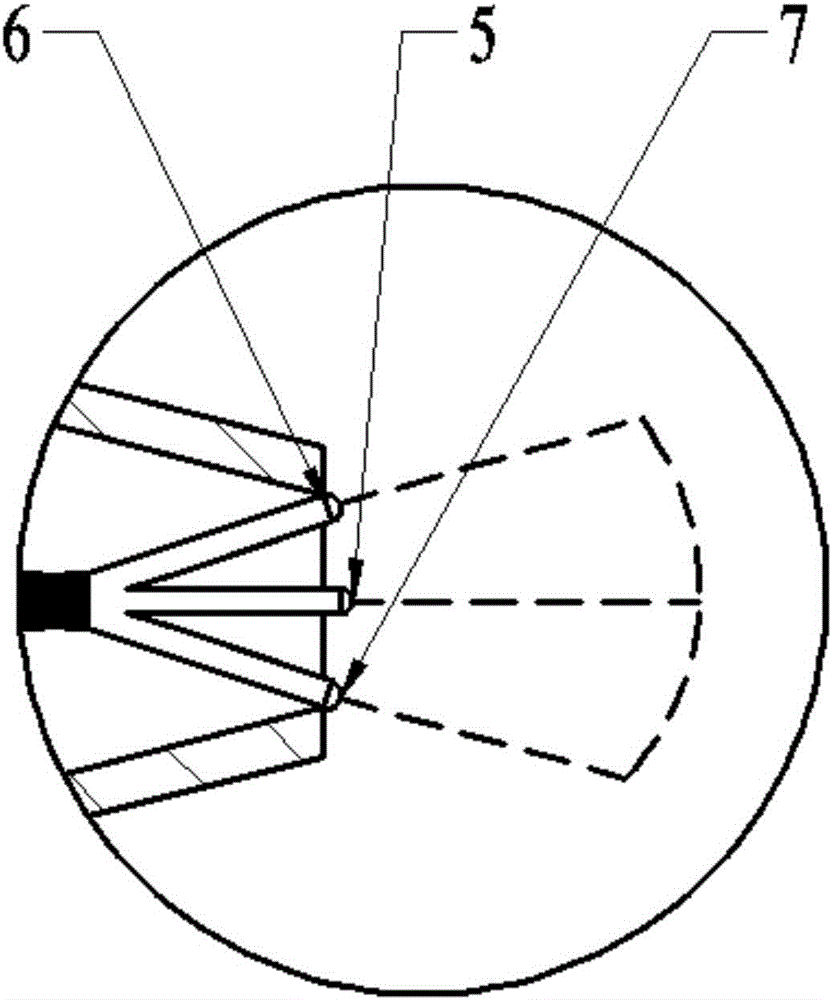

[0019] The light source in this embodiment indicates the positioning device, such as figure 1 As shown, it mainly includes a light source 1, a light guide 2, a flexible nozzle 3, a nozzle 4, a first daylighting cover 5, a second daylighting cover 6 and a third daylighting cover 7. The light source 1 is placed at one end of the flexible nozzle 3 , the light guide 2 is placed inside the flexible nozzle 3 , and the other end of the flexible nozzle 3 is provided with a nozzle 4 . see figure 2 , the light guide 2 is provided with a first daylighting cover 5, a second daylighting cover 6 and a third daylighting cover 7 at the nozzle 4. Wherein, the first daylighting cover 5 is positioned at the center line of nozzle 4, as positioning light emitter; Indicating light emitters.

[0020] The light source 1 emits light, which is transmitted to the first lighting cover 5 , the second lighting cover 6 and the third lighting cover 7 located at the nozzle 4 through the light guide 2 plac...

Embodiment 2

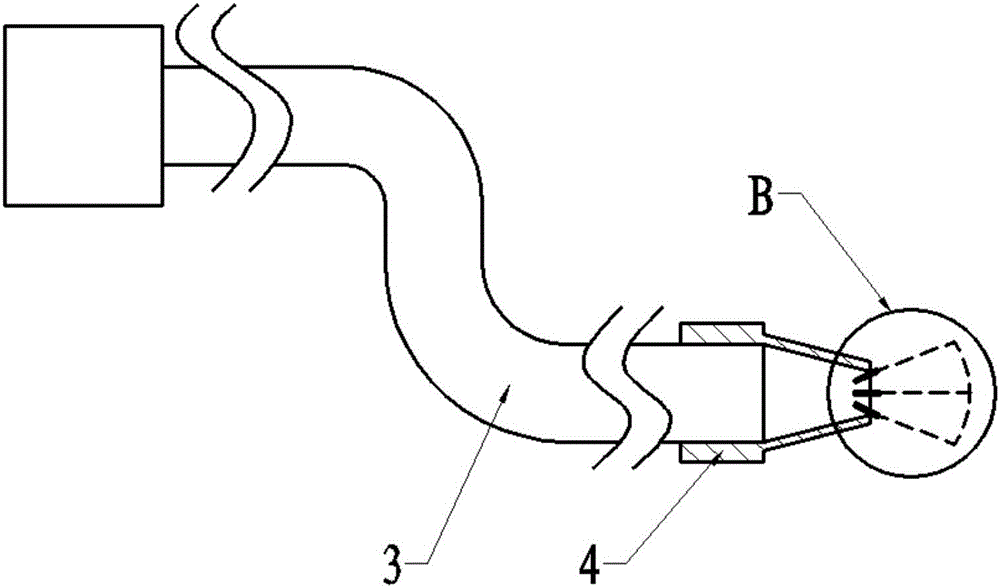

[0022] Such as image 3 As shown, the difference between this embodiment and the first embodiment is that the light in this embodiment does not need to be emitted by the light source and transmitted by the light guide, there is no light guide 2 in the flexible nozzle 3, and only three laser emitters are arranged on the inner wall of the nozzle 4 devices, that is, the first laser emitter 8 , the second laser emitter 9 and the third laser emitter 10 . All laser transmitters used have built-in power supply and can emit light directly. Wherein, the first laser emitter 8 is located on the center line of the nozzle 4, and serves as a light emitter for positioning, and the emitted light is accurately directed to the position that the cooling medium can reach. The second laser emitter 9 and the third laser emitter 10 are respectively located on the upper and lower sides or the left and right sides of the first laser emitter 8, as the light emitter for range indication, and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com