A kind of preparation method and application of montan wax resin modified product

A technology of montan wax resin and modified products, which is applied in the field of preparation of modified products of montan wax resin, can solve problems such as not involving detailed instructions, and achieve the effect of improving the level of applied research and increasing income and profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

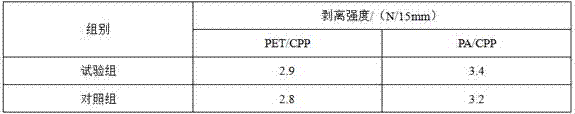

Embodiment 1

[0020] Embodiment 1: this montan wax resin modification is prepared according to the following steps:

[0021] Step 1. Place 1kg of montan wax resin in the reaction kettle, add co-solvent according to the mass ratio of co-solvent:montan wax resin=1:20, stir and mix under the condition of 50°C, the stirring speed is 40r / min, The stirring time is 20min; then add the reaction solution according to the mass ratio of montan wax resin:reaction solution=1:10, and then carry out stirring reaction under the condition of 100°C, the stirring speed is 80r / min, and the stirring time is 30min. Afterwards, cool to room temperature, stand for 10 minutes, and carry out liquid-solid separation, discharge the liquid, and keep the solid for later use;

[0022] Step 2, according to the mass ratio of montan wax resin: oil = 1:0.1, add oil into the reaction kettle after step 1 is completed, and then carry out stirring reaction at 150°C, the stirring speed is 80r / min, and the stirring time is 1h , a...

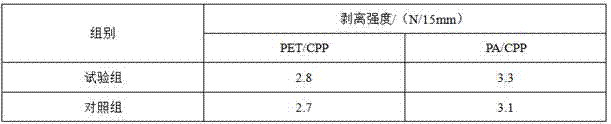

Embodiment 2

[0040] Embodiment 2: This montan wax resin modification is prepared according to the following steps:

[0041] Step 1. Place 1kg of montan wax resin in the reaction kettle, add co-solvent according to the mass ratio of co-solvent:montan wax resin=1:18, stir and mix evenly under the condition of 60°C, the stirring speed is 50r / min, Stirring time is 25min; then add the reaction solution according to the mass ratio of montan wax resin:reaction solution=1:15, then carry out stirring reaction under the condition of 130°C, the stirring speed is 90r / min, and the stirring time is 45min. Afterwards, cool to room temperature, stand for 20 minutes, and carry out liquid-solid separation, discharge the liquid, and keep the solid for later use;

[0042] Step 2, according to the mass ratio of montan wax resin: oil = 1:0.3, add oil into the reaction kettle after step 1 is completed, and then carry out stirring reaction at 180°C, the stirring speed is 90r / min, and the stirring time is 1.5 h, ...

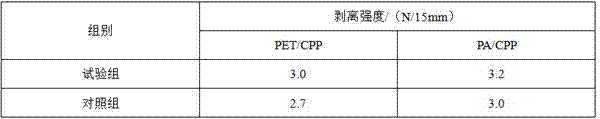

Embodiment 3

[0061] Step 1, place 1kg of montan wax resin in the reaction kettle, add the cosolvent by the mass ratio of cosolvent:montan wax resin=1:15, stir and mix evenly under the condition of 70°C, the stirring speed is 60r / min, Stirring time is 30min; Then add the reaction solution according to the mass ratio of montan wax resin:reaction solution=1:20, then carry out stirring reaction under the condition of 150°C, the stirring speed is 100r / min, and the stirring time is 60min. Afterwards, cool to room temperature, stand still for 30 minutes, and carry out liquid-solid separation, discharge the liquid, and keep the solid for later use;

[0062] Step 2. According to the mass ratio of montan wax resin: oil = 1:0.5, add oil into the reaction kettle after step 1 is completed, and then carry out stirring reaction at 200 ° C. The stirring speed is 100r / min, and the stirring time is 2h , add reactive polyamide resin by the mass ratio of montan wax resin after reaction finishes: reactive poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com