A kind of montan wax resin activation modification liquid and its production method and application

A montan wax resin and modified liquid technology, applied in the field of agricultural chemistry, can solve the problems of low yield of degradation products, failure to accurately grasp, long production cycle, etc., and achieve the goal of increasing revenue generation profits, good promotion value, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

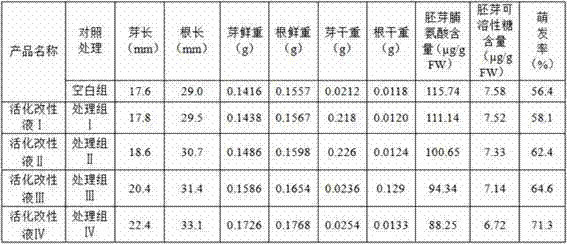

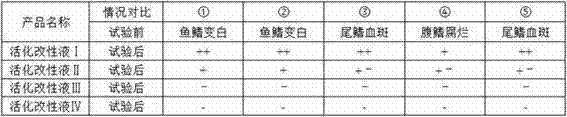

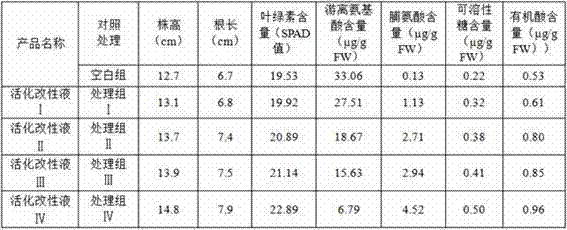

Examples

Embodiment 1

[0023] The montan wax resin activation modified liquid described in the present embodiment is obtained according to the following production steps:

[0024] (1) Crush the rice flour and pass through a 10-mesh sieve to obtain rice flour and set aside;

[0025] (2) Put the montan wax resin in the reaction kettle, add the reaction aid according to the mass ratio of reaction aid: montan wax resin = 1:4, stir under normal pressure conditions of 50°C, and the stirring speed is 40r / min , the stirring time is 30min;

[0026] (3) After step (2) is completed, put rice powder into the reactor according to the mass ratio of rice powder: montan wax resin = 1:90, and then press the mass ratio of montan wax resin: reaction solution = 1:5 Put the reaction liquid into the reaction kettle, and then stir it under a closed and pressurized condition at 100°C. The stirring speed is 80r / min, the stirring time is 0.5h, and the gauge pressure is 0.2Mpa. After the reaction is completed, reduce the pre...

Embodiment 2

[0072] The montan wax resin activation modified liquid described in the present embodiment is obtained according to the following production steps:

[0073] (1) Crush the rice flour and pass through a 20-mesh sieve to obtain rice flour and set aside;

[0074] (2) Put the montan wax resin in the reaction kettle, add the reaction aid according to the mass ratio of reaction aid: montan wax resin = 1:6, stir under the normal pressure condition of 60°C, and the stirring speed is 50r / min , the stirring time is 45min;

[0075] (3) After step (2) is completed, put rice powder into the reaction kettle according to the mass ratio of rice powder: montan wax resin = 1:60, and then press the mass ratio of montan wax resin: reaction solution = 1:10 Put the reaction solution into the reaction kettle, and then stir it under a closed and pressurized condition at 150°C. The stirring speed is 90r / min, the stirring time is 1h, and the gauge pressure is 0.35Mpa. After the reaction is completed, r...

Embodiment 3

[0115] The montan wax resin activation modified liquid described in the present embodiment is obtained according to the following production steps:

[0116] (1) Crush the rice flour and pass through a 30-mesh sieve to obtain rice flour and set aside;

[0117] (2) Put the montan wax resin in the reaction kettle, add the reaction aid according to the mass ratio of reaction aid: montan wax resin = 1:8, stir under the normal pressure condition of 70°C, and the stirring speed is 60r / min , the stirring time is 60min;

[0118] (3) After step (2) is completed, put rice powder into the reactor according to the mass ratio of rice powder: montan wax resin = 1:30, and then press the mass ratio of montan wax resin: reaction solution = 1:20 Put the reaction liquid into the reaction kettle, and then stir it under a closed pressure condition of 200°C. The stirring speed is 100r / min, the stirring time is 2h, and the gauge pressure is 0.5Mpa. After the reaction is completed, reduce the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com