Mini-type piling device for construction site

A piling device and construction site technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as troublesome, unsafe for people to support, and achieve the effect of convenient operation, improved efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

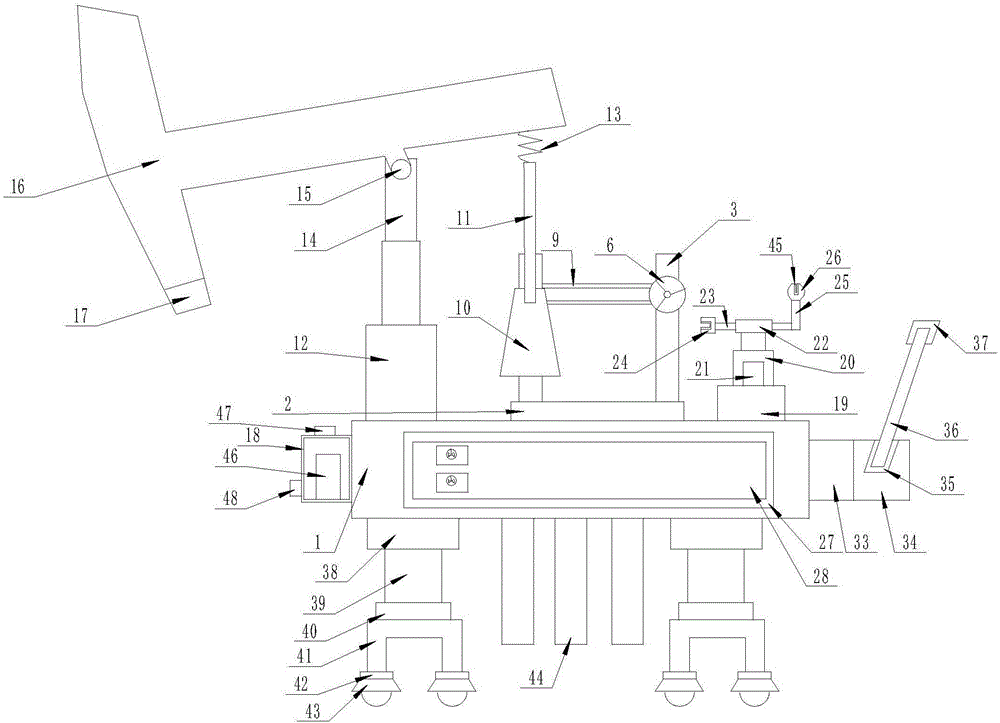

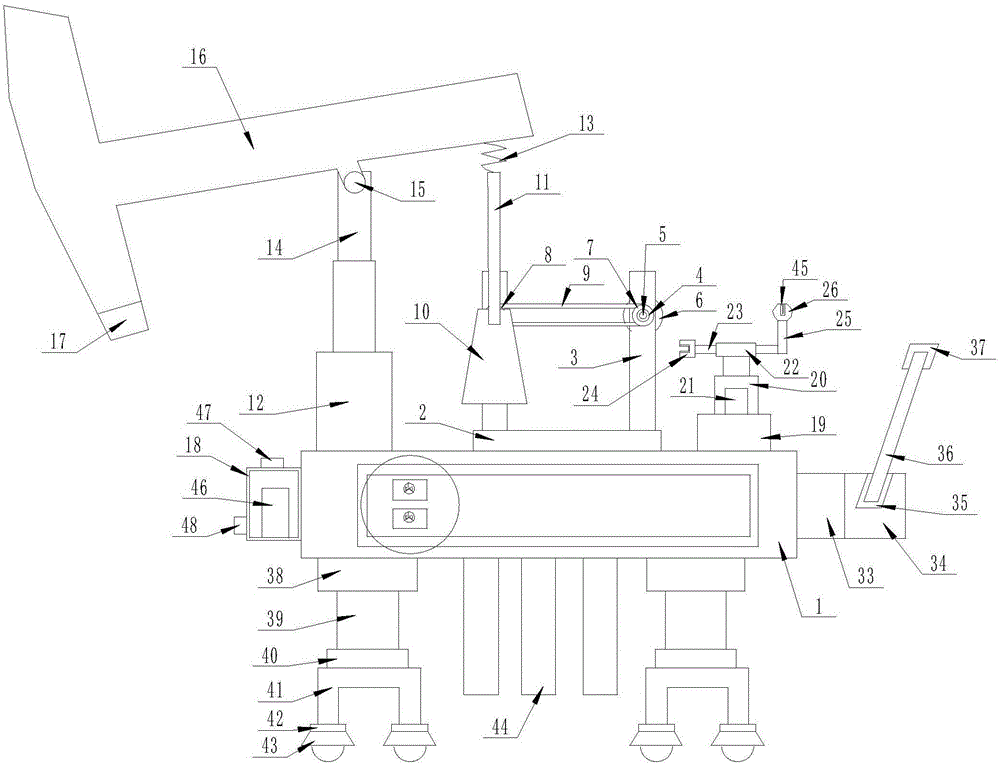

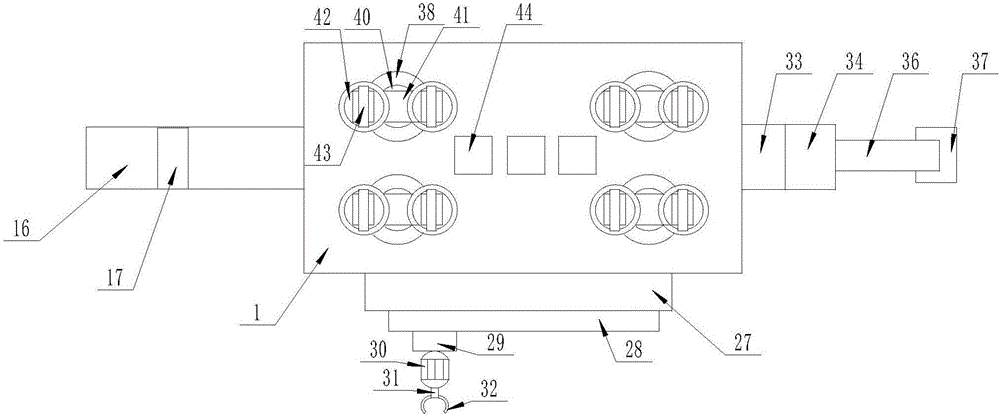

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4Shown, a kind of construction site miniature piling device, comprises bar-shaped base (1), described bar-shaped base (1) lower surface is provided with moving mechanism, and described bar-shaped base (1) upper surface is provided with automatic Beating mechanism, a clamping mechanism is provided at one end of the upper surface of the strip-shaped base (1), a pushing mechanism is provided on the side surface of the strip-shaped base (1), and the front side of the strip-shaped base (1) There is a digging mechanism on the surface, and the automatic beating mechanism is supported by a rectangular mounting platform (2) arranged on the upper surface of the strip base (1) and a set of N-shaped supports fixedly connected to the upper surface of the rectangular mounting platform (2). Frame (3), the No. 1 circular through hole (4) that is opened on the side surface of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com