Connection part for installing ceiling, installation structure and installation method

A technology for installing structures and connectors, which is applied to building components, building structures, buildings, etc., can solve problems such as high production costs, complex keel connection structures, and inconvenient installation, and achieve simple structures, which are conducive to processing and production. The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

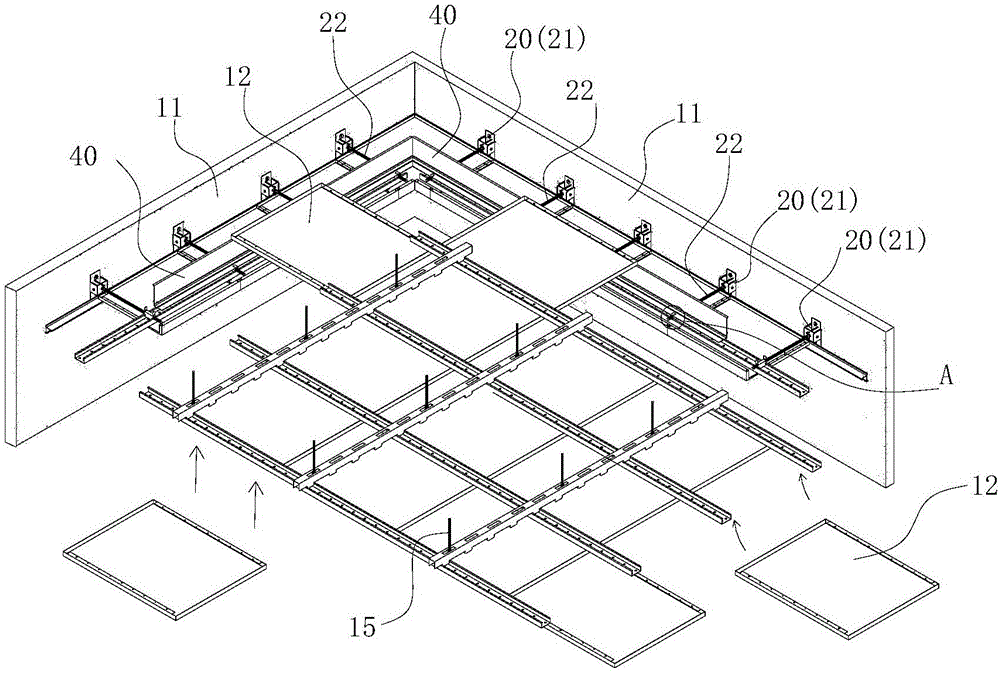

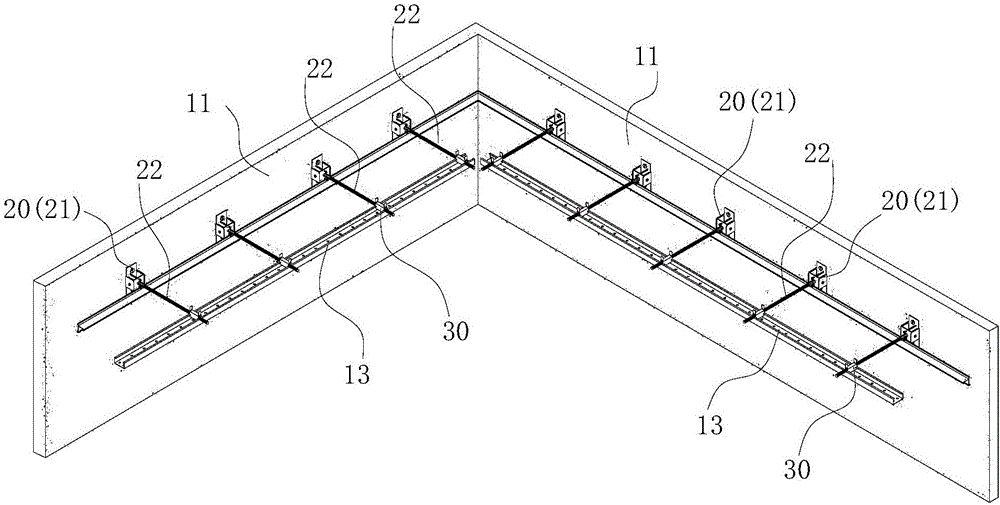

[0055] Such as figure 1 , figure 2 , image 3 As shown, the ceiling installation structure, the installation structure described in this embodiment adopts the upper and lower two-level installation method: that is, the first-level ceiling is installed on the periphery, the ceiling 12 is installed on the wall 11 through the ceiling installation leveling support structure, and the keel 13 passes The connecting piece 30 is connected with the supporting rod 22, and the light blocking plate 40 is installed on the connecting piece 30; the second-level ceiling is the main area of the ceiling, which is supported by the suspender 15, the skeleton 14 (or called the main keel), and the keel 13; as follows:

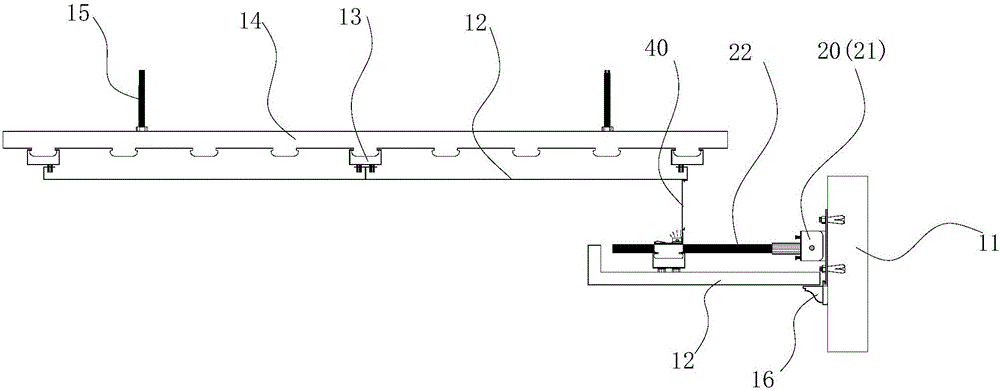

[0056] Ceiling-mounted leveling support structures such as Figure 2 to Figure 9As shown, it includes a fixed base body 20, a movable base body 21 and a support rod 22, the fixed base body 20 is provided with a fixed portion, the movable base body 21 and the fixed base body 20 ...

Embodiment 2

[0092] Such as Figure 21 , Figure 22 As shown, the ceiling installation structure, the installation structure described in this embodiment adopts the upper and lower two-level installation method: that is, the first-level ceiling is the main area for installation, and the ceiling 12 is installed on the wall 11 through the ceiling installation leveling support structure, and the keel 13 is connected to the support rod 22 through the connecting piece 30, and the light blocking plate 40 is installed on the connecting piece 30; the second-level ceiling is located in the central area, and is supported by the suspender 15, the skeleton 14, and the keel 13; the principle is the same as that of the first embodiment, I won't repeat them here.

Embodiment 3

[0094] Such as Figure 23 , Figure 24 As shown in the ceiling installation structure, the installation structure described in this embodiment adopts the upper and lower three-level installation method: that is, the first-level ceiling and the second-level ceiling are installed on the wall 11 through the ceiling installation leveling support structure, and are staggered up and down. The keel 13 is connected to the support rod 22 through the connecting piece 30, and the light blocking plate 40 is installed on the connecting piece 30; while the third-level ceiling is located in the central area, supported by the suspender 15, the skeleton 14, and the keel 13; its principle is the same as The first embodiment is the same, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com