Energy-saving composite window

A composite window and aluminum alloy frame technology, which is applied in the direction of window/door, window glass installation, synthetic resin layered products, etc., can solve the problem of not being able to reduce indoor lighting power consumption, windows do not have reflection function, and cannot achieve Energy saving and other issues, to achieve the effects of reducing light power consumption, good transparency, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

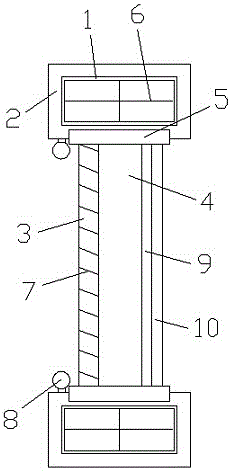

[0018] Such as figure 1 As shown, an energy-saving composite window includes an aluminum alloy frame 1, a solid wood sheath 2, a plexiglass layer 3 and a tempered glass layer 4, the solid wood sheath 2 is arranged outside the aluminum alloy frame 1, and the solid wood sheath 2 Glue connection with the aluminum alloy frame 1, the inner side of the solid wood sheath 2 is inlaid with a rubber layer 5, the organic glass layer 3 and the tempered glass layer 4 are arranged on the inner side of the rubber layer 5, and the rubber layer 5 is connected with the organic glass layer 3 respectively. It is glued and connected with the tempered glass layer 4, the aluminum alloy frame 1 is hollow, and the aluminum alloy frame 1 is provided with a cross-shaped reinforcing rib 6, and the cross-shaped reinforcing rib 6 is integrally formed with the aluminum alloy frame 1, and the The plexiglass layer 3 is provided with a plurality of reflective sheets 7, the reflective sheets 7 are equidistantly...

Embodiment 2

[0025] Such as figure 1 As shown, an energy-saving composite window includes an aluminum alloy frame 1, a solid wood sheath 2, a plexiglass layer 3 and a tempered glass layer 4, the solid wood sheath 2 is arranged outside the aluminum alloy frame 1, and the solid wood sheath 2 Glue connection with the aluminum alloy frame 1, the inner side of the solid wood sheath 2 is inlaid with a rubber layer 5, the organic glass layer 3 and the tempered glass layer 4 are arranged on the inner side of the rubber layer 5, and the rubber layer 5 is connected with the organic glass layer 3 respectively. It is glued and connected with the tempered glass layer 4, the aluminum alloy frame 1 is hollow, and the aluminum alloy frame 1 is provided with a cross-shaped reinforcing rib 6, and the cross-shaped reinforcing rib 6 is integrally formed with the aluminum alloy frame 1, and the The plexiglass layer 3 is provided with a plurality of reflective sheets 7, the reflective sheets 7 are equidistantly...

Embodiment 3

[0032] Such as figure 1 As shown, an energy-saving composite window includes an aluminum alloy frame 1, a solid wood sheath 2, a plexiglass layer 3 and a tempered glass layer 4, the solid wood sheath 2 is arranged outside the aluminum alloy frame 1, and the solid wood sheath 2 Glue connection with the aluminum alloy frame 1, the inner side of the solid wood sheath 2 is inlaid with a rubber layer 5, the organic glass layer 3 and the tempered glass layer 4 are arranged on the inner side of the rubber layer 5, and the rubber layer 5 is connected with the organic glass layer 3 respectively. It is glued and connected with the tempered glass layer 4, the aluminum alloy frame 1 is hollow, and the aluminum alloy frame 1 is provided with a cross-shaped reinforcing rib 6, and the cross-shaped reinforcing rib 6 is integrally formed with the aluminum alloy frame 1, and the The plexiglass layer 3 is provided with a plurality of reflective sheets 7, the reflective sheets 7 are equidistantly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com