Powder coating as well as preparation method and application thereof

A powder coating and graphene technology, applied in powder coatings, natural rubber coatings, reflective/signal coatings, etc., can solve the problems of affecting the reflective effect of road markings, easy detachment of reflective beads, and failure to provide adhesion, etc., to achieve Excellent reflective effect, high weather resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The powder coating in this example is white and has the following formula:

[0065] Element parts by weight C5 Hydrogenated Petroleum Resin 16 thermoplastic acrylic resin 8 natural rubber powder 5 talcum powder 8 Titanium dioxide 33.5 Quartz sand 5.0 Reflective aluminized ceramic beads 22 Acrylic leveling agent 1 plasticizer 1 Graphene oxide 0.5

Embodiment 2

[0067] The powder coating in this example is white and has the following formula:

[0068] Element parts by weight C5 Hydrogenated Petroleum Resin 20 thermoplastic acrylic resin 6 polyisoprene rubber 3 talcum powder 8 Titanium dioxide 35.5 Quartz sand 3 Reflective aluminized ceramic beads 25 Acrylic leveling agent 1 plasticizer 1 Graphene oxide 0.3

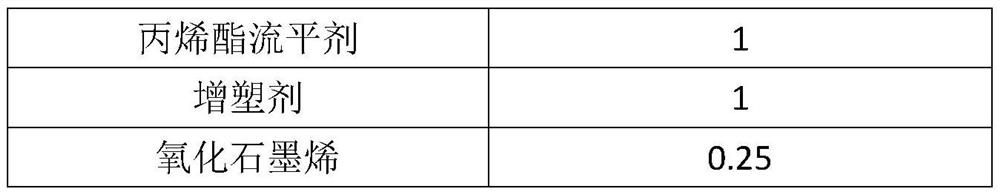

Embodiment 3

[0070] The powder coating in this example is yellow and has the following formulation:

[0071]

[0072]

[0073] The powder coating in embodiment 1 to embodiment 3 adopts following preparation method to prepare:

[0074] C5 petroleum resin fixed bed hydrogenation process;

[0075] The fixed-bed hydrogenation process of C5 petroleum resin is mainly divided into one-stage hydrogenation process and two-stage hydrogenation process, and the present invention adopts the method of two-stage hydrogenation process.

[0076] Specifically: first dissolve C5 petroleum resin and toluene in a mixer, then let the C5 petroleum resin solution enter the heating furnace, mix with hydrogen and enter a hydrogenation reactor for hydrogenation reaction, and the hydrogenated material passes through the separator After cooling and separation, the intermediate product after separating hydrogen and hydrogen chloride gas enters the storage tank, then sends it to the heating furnace for heating, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com