Array float-type wave power generation device

A power generation device and wave energy technology, which is applied to ocean energy power generation, engine components, machines/engines, etc., can solve the problems of inconvenient operation and maintenance, oil pollution of marine water bodies, high manufacturing cost, etc. The effect of energy utilization and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

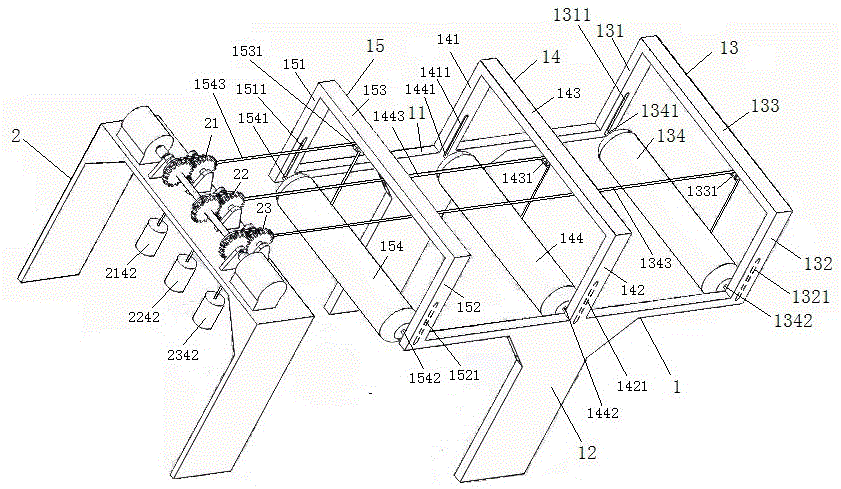

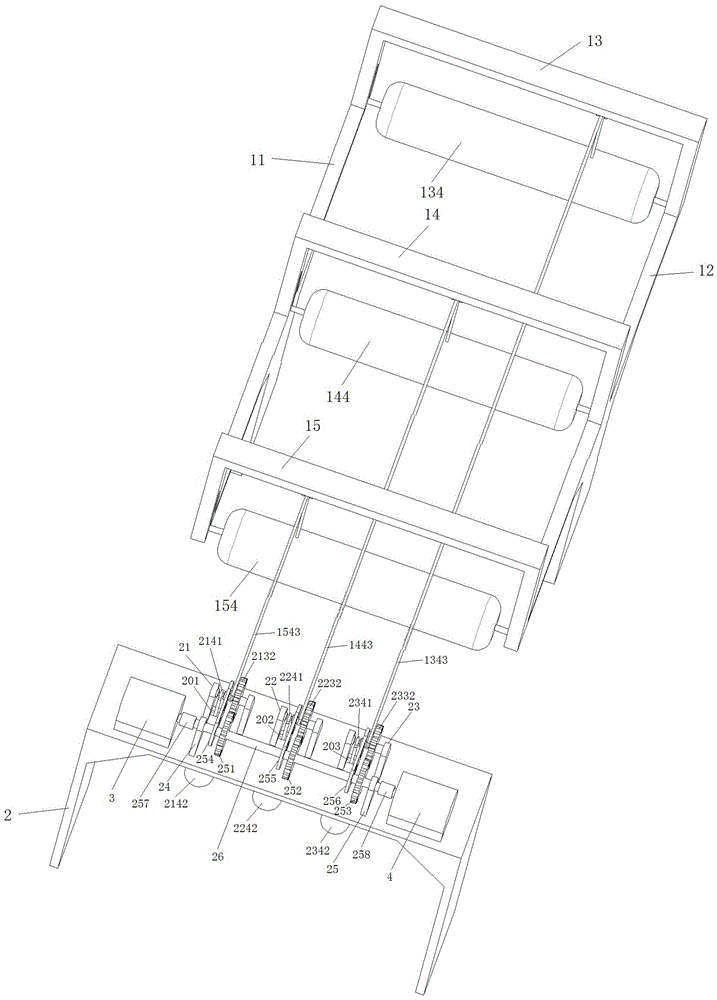

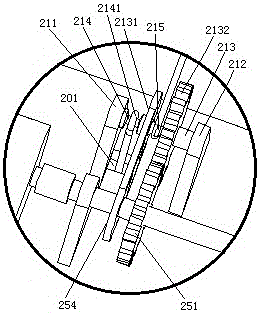

[0023] The array buoy type wave energy generating device of the present invention will be further described in detail below with reference to the accompanying drawings.

[0024] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the array buoy type wave energy generating device of the invention includes a generating device body, and the generating device body is formed by a front frame 1 and a rear frame 2 .

[0025]Described front frame 1 is formed by left and right support seat 11,12 and the front support 13 that is distributed on left and right support seat 11,12, middle support 14 and rear support 15. The left and right bracket seats 11, 12 are in the shape of a "T", the front bracket 13, the middle bracket 14 and the rear bracket 15 are in the shape of an inverted groove, and the front bracket 13 in the shape of an inverted groove is all in the shape of an inverted groove. , the middle bracket 14 and the rear bracket 15 bridge over the upper end surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com