Integrated four-point contact ball bearing with heart-shaped roller paths

A four-point contact, integral technology, applied in the direction of ball bearings, bearing components, shafts and bearings, can solve the problems of increased production costs, affecting the production system, easy loose sets, etc., and achieve the effect of improving the stability and life of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

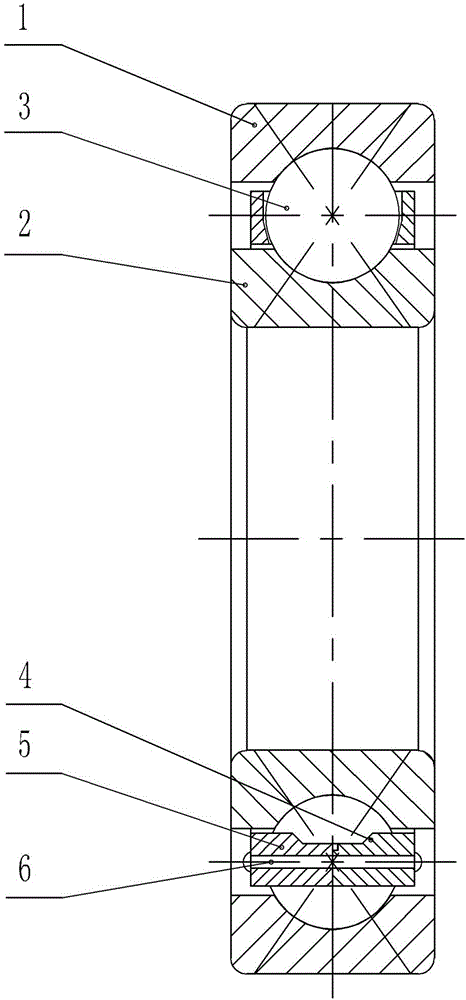

[0010] A peach-shaped raceway integral four-point contact ball bearing, mainly composed of an outer ring 1, an inner ring 2, a plurality of steel balls 3, a cage seat 4 and a cage cover 5, and each steel ball 3 is mounted on In a pocket corresponding to the cage seat 4, the cage seat 4 with a plurality of steel balls 3 is arranged in the raceway formed by the outer ring 1 and the inner ring 2, and the cage cover 5 is installed on the cage seat 4 to keep The frame base 4 and the cage cover 5 are fixedly connected by a plurality of rivets 6 . It is characterized by:

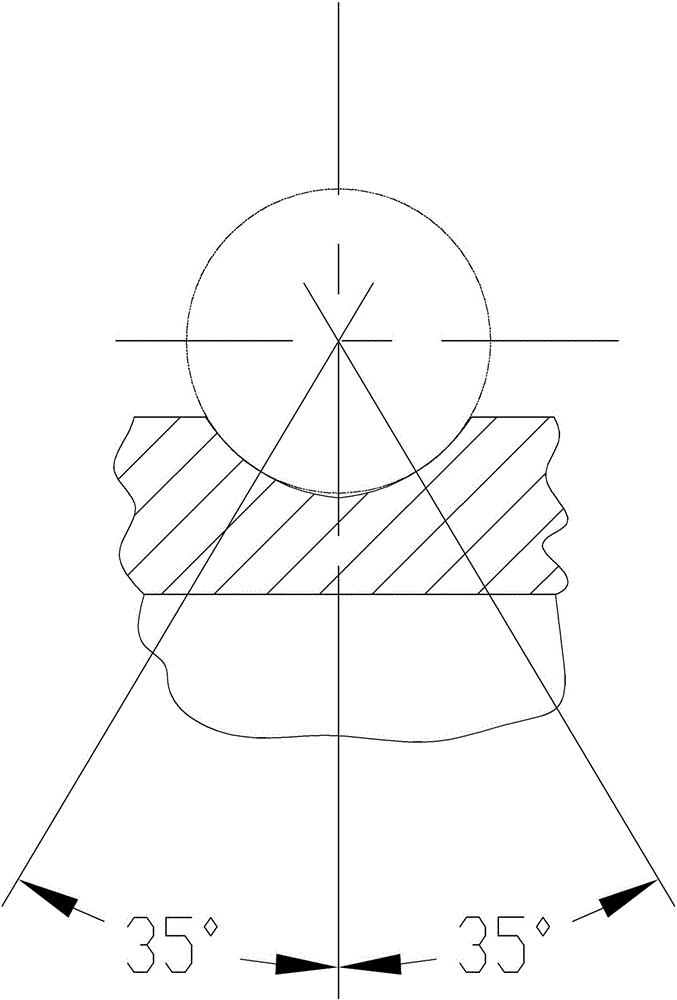

[0011] The inner ring 2 is an integral structure, and the outer wall of the inner ring 2 is provided with two sections 35 。 The peach-shaped groove raceway where the angle contacts with the steel ball 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com