Tool of using vertical type drilling machine for hole depth measurement and processing guarantee

A vertical drilling machine and hole depth technology, which is applied in the direction of mechanical depth measurement, etc., can solve problems such as processing guarantees that cannot be effectively solved, and achieve the effects of simple and convenient installation, accurate measurement, and convenient overall replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

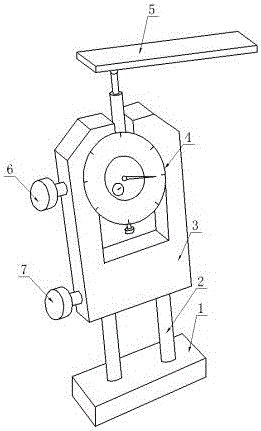

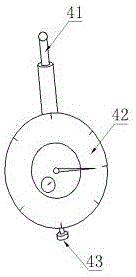

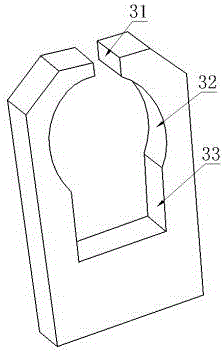

[0021] Such as figure 1 , 2 , 3, the present invention includes a base 1 standing on the upper surface of the workbench, two or three support rods 2 fixed on the base 1 by threads, located above the support rod 2 and fixing the support rod 2 by the lower adjusting screw 7 The bracket 3, the bracket 3 is provided with a similar arch bridge, for the through groove for measuring meter 4 to put in, including measuring groove 31, circular groove 32, adjustment groove 33, respectively corresponding to accommodate the measuring end 41 of measuring meter 4, the meter Body 42, adjustment end 43, the upper side of bracket 3 is provided with the upper adjustment screw 6 of fixed measuring gauge 4. In order to make the dimensions guaranteed by measurement or processing accurate and effective, a position transmission block 5 is also set up, such as Figure 4 Shown, the upper surface of its one end is close to the lower surface of a certain plane that lifts synchronously with the drill bi...

Embodiment 2

[0024] Such as Figure 5 As shown, this embodiment is basically consistent with Embodiment 1, the only difference is that the end of the position transmission block 5 and the drilling machine are fixed in a box shape, and a certain plane of the vertical drilling machine that is synchronously lifted and lowered with the drill bit is inserted into it. , In this way, the position transfer block 5 is movable, and it is only installed when needed, so as to prevent the drilling machine from being convenient for other operations because of the welding position transfer block 5 .

Embodiment 3

[0026] Such as Figure 6 As shown, in this embodiment, on the basis of implementation 1, a level 8 is provided at the bottom of the measuring groove 31 of the bracket 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com