Machine vision-based glass surface detect detection apparatus and method

A glass surface and defect detection technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low detection accuracy and no motion control

- Summary

- Abstract

- Description

- Claims

- Application Information

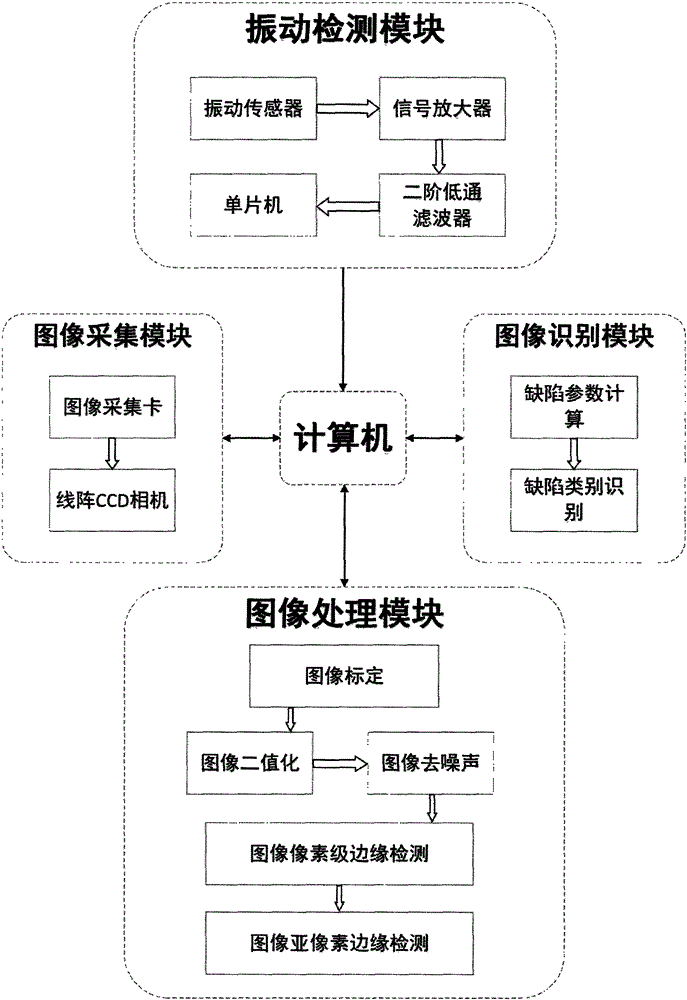

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in more detail and complete below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

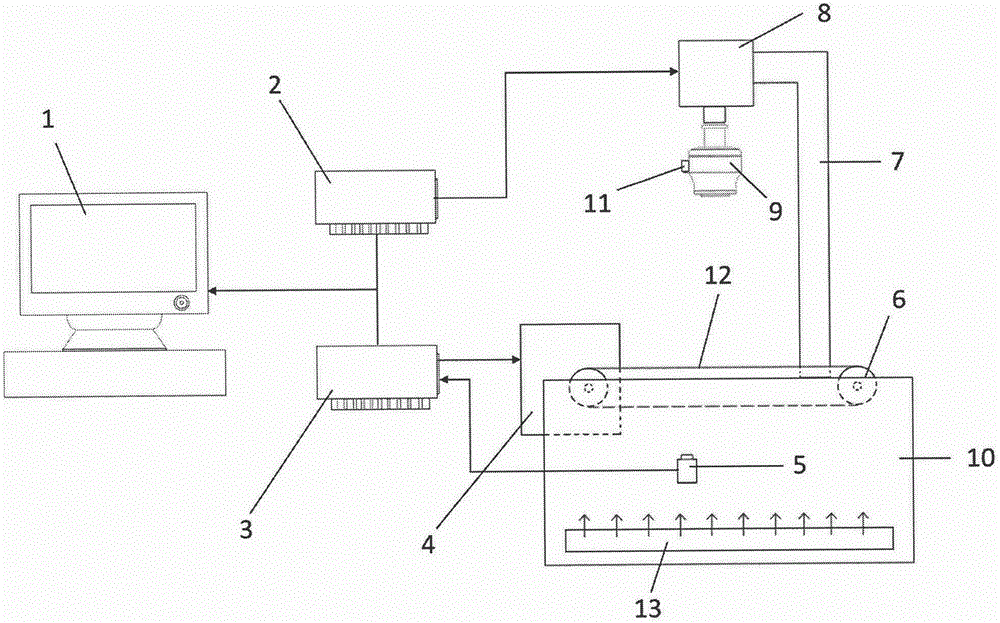

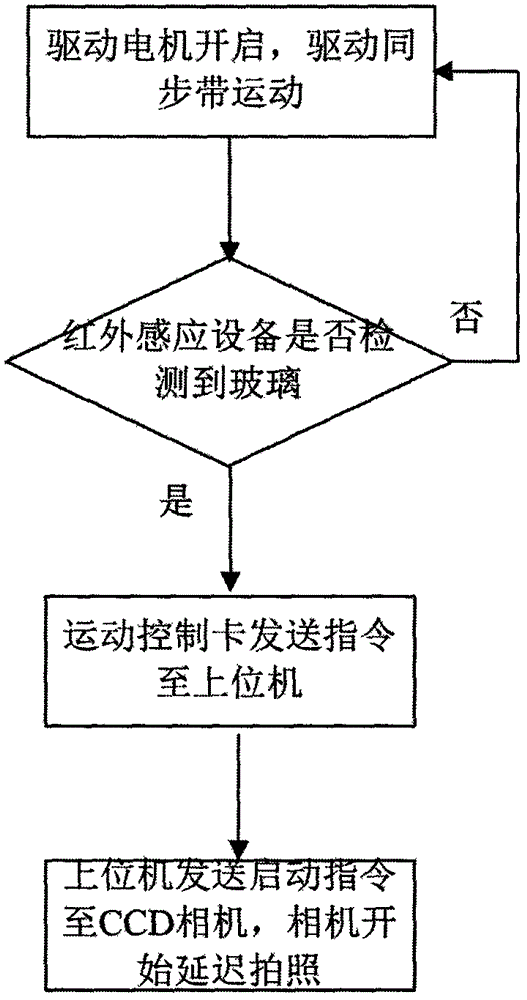

[0042] see figure 1 , the glass surface defect detection device based on machine vision of the present invention consists of a detection platform and a detection system, wherein:

[0043] The test bench includes a workbench 10 for clamping the glass to be tested, a pillar 7 supported on the workbench, a mounting plate 8 above the pillar, a motion mechanism arranged on the workbench and a workbench arranged on the workbench. The LED light source 13 and the CCD camera 9 at the bottom of the table, wherein the motion mechanism is made up of a synchronous belt transmission mechanism on both sides of the workbench and a drive motor 4 connected with the synchronous belt; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com