Material performance test device applicable to high-temperature vacuum environment

A material performance, high temperature vacuum technology, applied in the investigation phase/state change and other directions, can solve the problems of the deformation measurement component not working properly, the accuracy of the test test results being low, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The core of the present invention is to provide a material performance testing device suitable for high-temperature vacuum environment, so as to improve the accuracy of test results.

[0020] In order to enable those skilled in the art to better understand the technical solutions provided by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

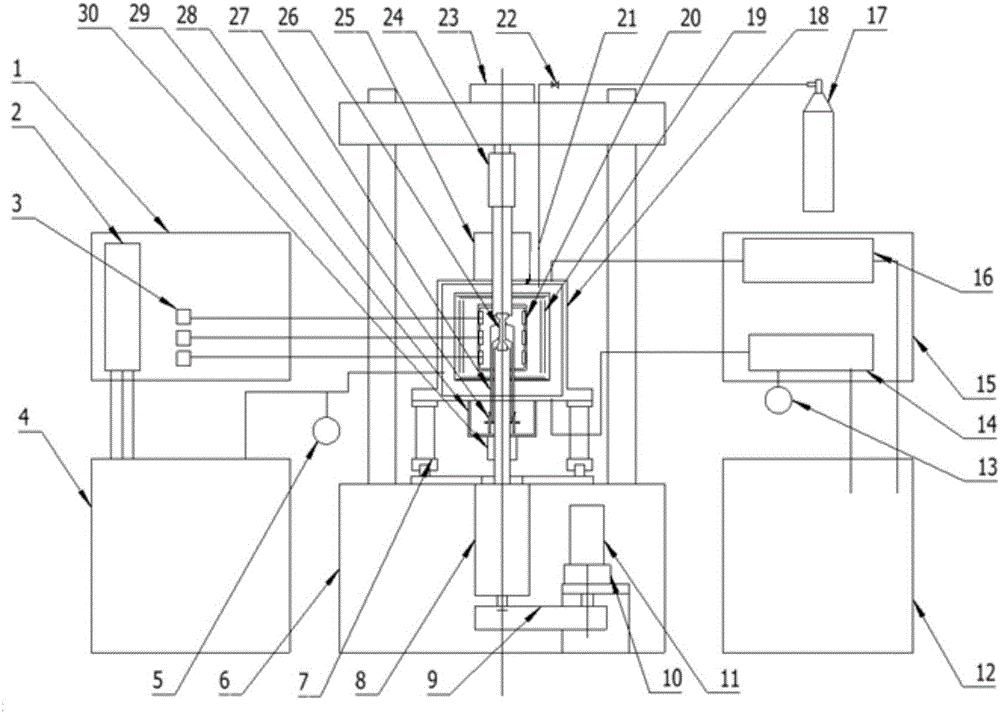

[0021] Such as figure 1 As shown, the embodiment of the present invention provides a material performance testing device suitable for a high-temperature vacuum environment, including a vacuum furnace box body, a heating device 20, a clamp for fixing a sample 26 and a tool for measuring The deformation measurement assembly 27 of the deformation amount of the sample 26 gauge, the heating device 20 is used to heat the sample, the vacuum furnace box includes a first vacuum chamber 18 and a second vacuum chamber 29, the heating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com