Transformer fault monitoring method

A transformer fault and transformer technology, which is applied in the field of internal fault monitoring of power equipment, can solve the problems of monitoring lag and direct monitoring without taking advantage of gas floating, so as to prevent the deterioration of faults, improve the detection efficiency and effect, and protect the safety of transformers and power grids. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

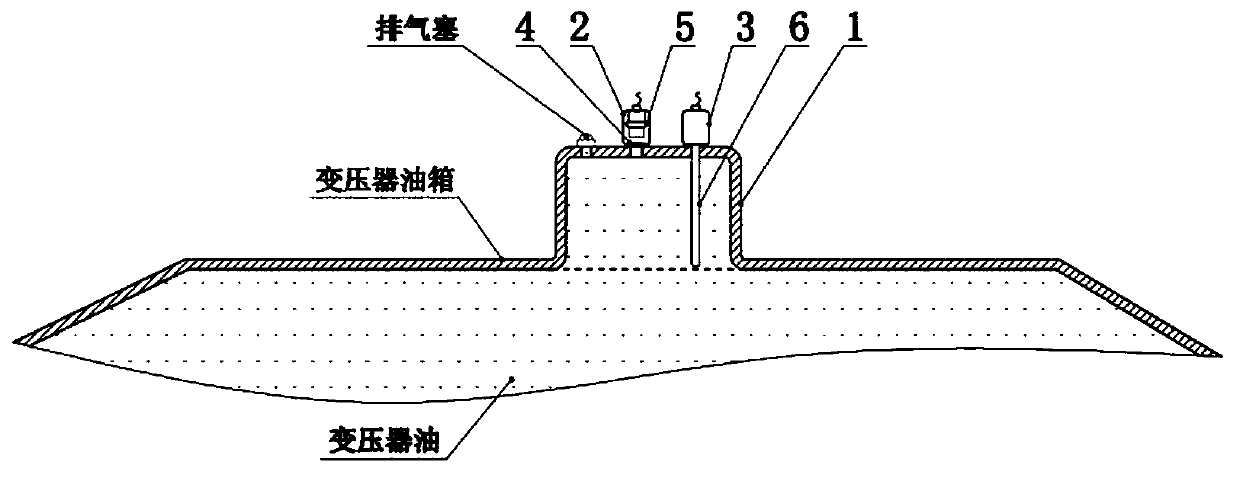

[0034] Embodiment 1: as figure 1As shown, in the part where the transformer fault gas floats upward or is easy to store, such as the upper cover of the oil tank, a gas collection chamber 1 is provided, and a gas composition detection device 2 and a gas volume detection device 3 are arranged on the upper part of the gas collection chamber. The gas component detection device 2 includes a detection element 5 and circuit elements for power supply and signal processing of the detection element. The detection element 5 can choose various types of combustible gas sensors, such as infrared type, semiconductor type, electrochemical type and catalytic combustion type. In order to realize the detection and prevent the insulating oil from polluting the detection element, the oil-gas isolation film 4 can be used to isolate the detection element from the insulating oil. The oil-gas isolation film 4 can be made of polytetrafluoroethylene material with good air permeability and isolation of i...

Embodiment 2

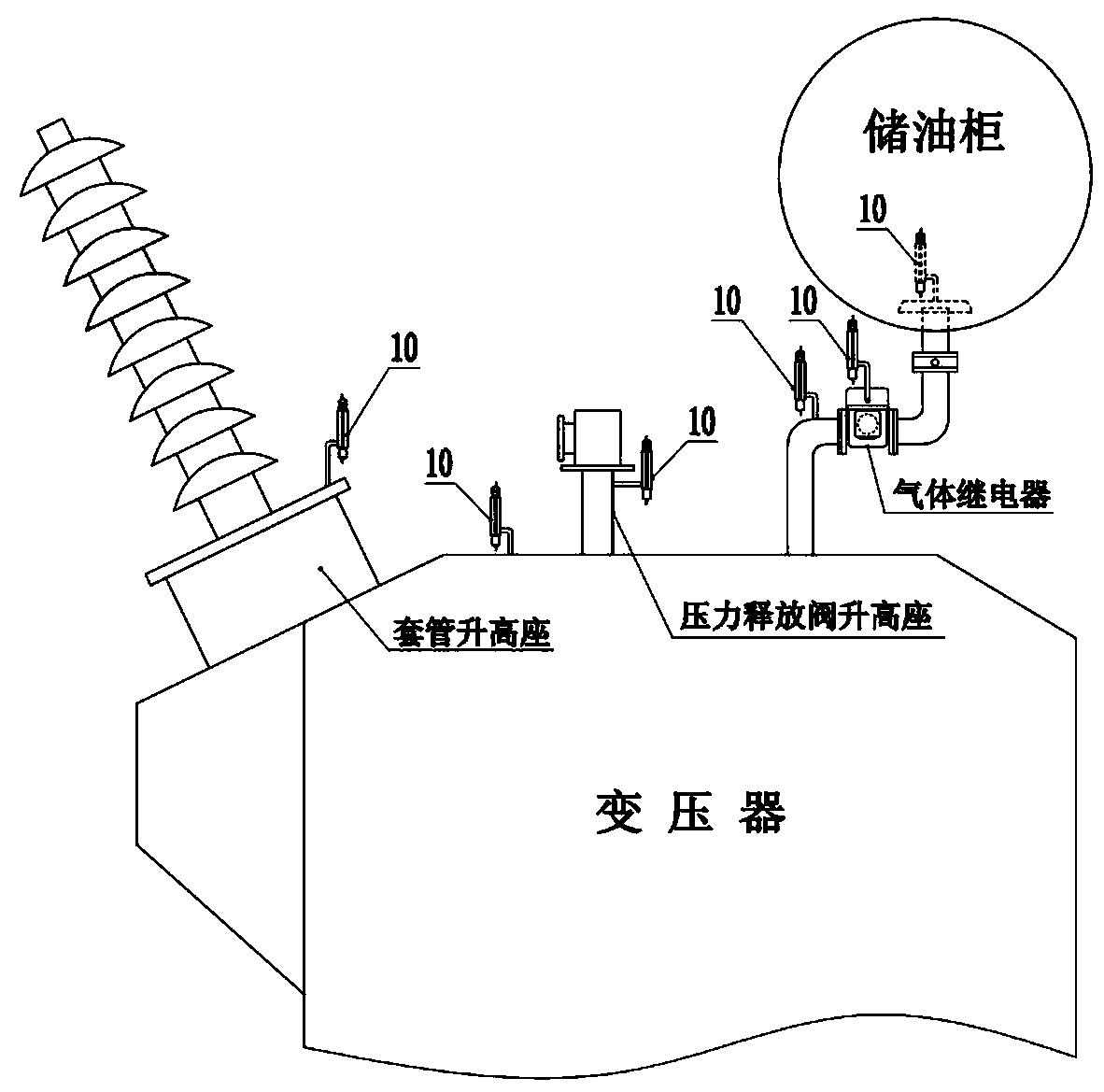

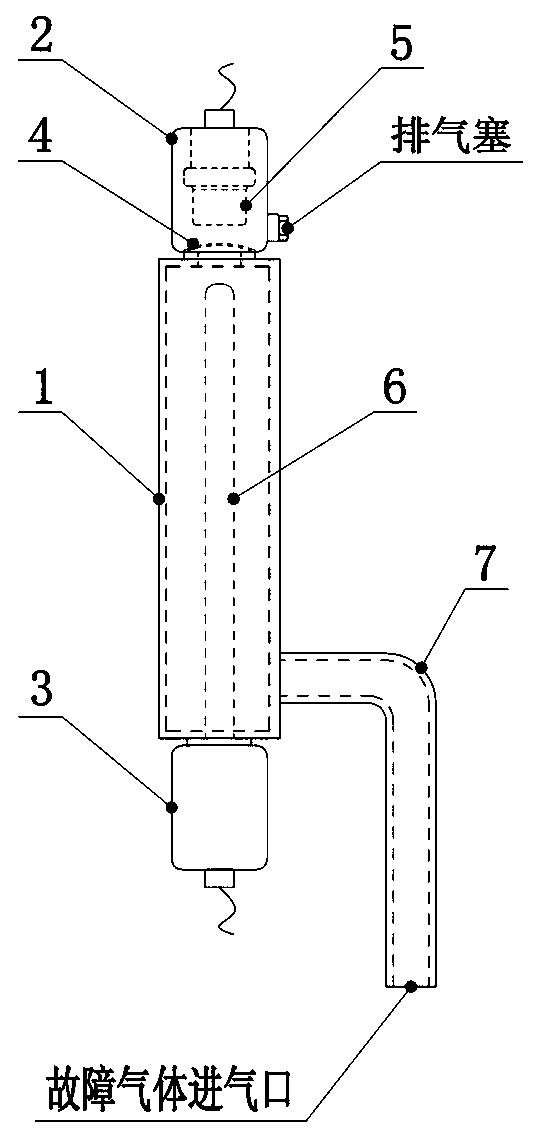

[0037] Embodiment 2: as figure 2 As shown, in the parts where the transformer fault gas floats upward or is easy to store, such as the upper cover of the oil tank, the rising seat of the bushing, the rising seat of the pressure release valve, the connection pipe of the oil tank leading to the gas relay, and the connection port of the gas relay and the oil storage tank At the high point where the gas is stored or passed, a detection component that communicates with the insulating oil inside the transformer is installed. Detection components such as image 3 As shown, it adopts a type that is easy to install, and is composed of a gas collection chamber 1, a gas component detection device 2 and a gas volume detection device 3. The air-collecting cavity is provided with a connecting port or connecting pipe 7 to communicate with the inside of the transformer. For the convenience of disassembly, a valve can be arranged at the connection with the transformer. The gas component det...

Embodiment 3

[0040] Embodiment 3: Gas relays are provided on the connecting pipes leading to the oil conservator from the upper part of the existing transformer oil tank, such as Figure 4 with Figure 5 As shown, the gas component detection device 2 and the gas quantity detection device 3 are arranged on the gas relay, communicated with the gas collection chamber of the gas relay, and the gas collection chamber of the gas relay is used as the gas collection chamber of the detection component. The gas component detection device 2 can be installed on the upper part of the gas collection chamber of the gas relay, guide the gas collected in the gas collection chamber to the gas detection element 5 through the air guide hole and the pipeline, and isolate the detection element 5 from the oil through the oil-gas separation film . The gas sampling hole on the upper part of the side wall of the gas relay can also be used to connect the tee, the upward pipeline is connected to the gas composition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com