Three-arc spring for grid positioning and utilization method of three-arc spring

A three-bend spring and grid technology, applied in the field of nuclear reactor core fuel assemblies, can solve the problems of grid spring stiffness, wear, and fuel rod damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

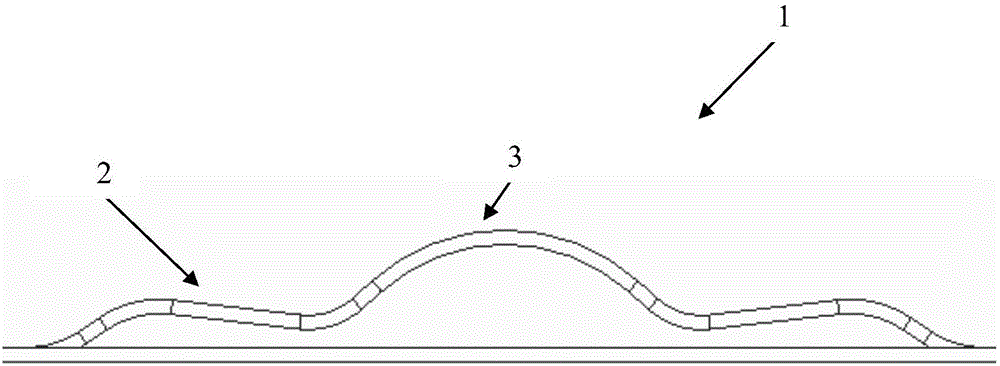

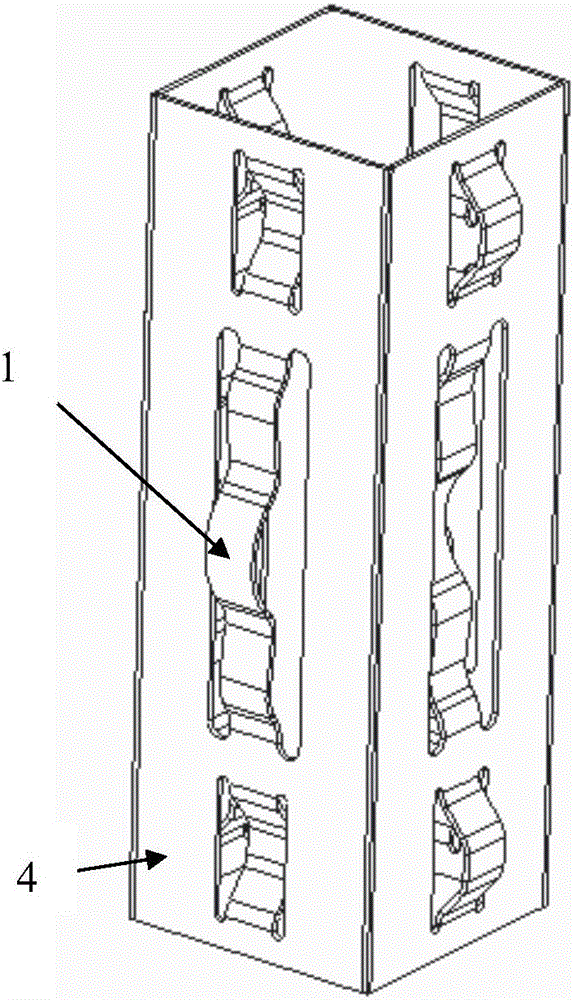

[0027] figure 1 A preferred embodiment of the triple-bend spring of the present invention is shown. Such as figure 1 As shown, the three-curved spring 1 for grid positioning is composed of three wavy arches, which resemble the number "3". In order for the three-curved spring to work stably, the three arches are roughly divided into two types of heights and two types of radians, wherein the height and radians and height and width of the first arch 2 on both sides are equal, while the height of the second arch 3 in the middle is greater than The height of the first arch 2 on both sides, the radian of the second arch 3 in the middle is also greater than the radian of the first arch 2 on both sides.

[0028] Preferably, the height ratio of the first arch 2 on both sides to the second arch 3 in the middle is about 1:2, the radians of the first arch 2 on both sides are equal, greater than 30° and less than 120°, and the second arch 3 in the middle The arc is greater than 60° and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com