Reciprocating type feeding mechanism on LED chip mounting machine

A technology of LED placement machine and feeding mechanism, which is applied in the direction of assembling printed circuits, electrical components, printed circuits, etc. of electrical components, which can solve the problems of low efficiency and long time for refueling, and achieve convenient use, stable mechanism and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

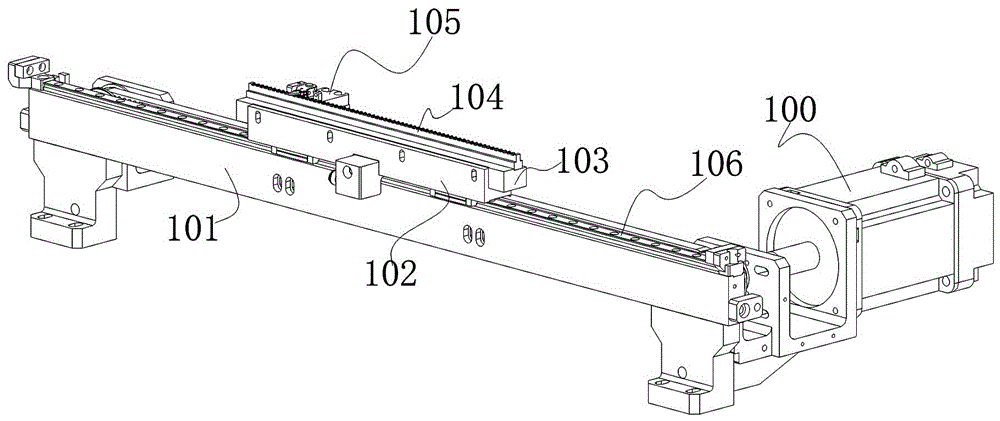

[0010] combine figure 1 , describe the specific implementation of the present invention in detail, but do not make any limitation on the claims. The reciprocating feeding mechanism used on the LED placement machine of the present invention includes a motor 100, and the motor 100 is connected with a transmission belt 106. The below of 106 is provided with transmission block base 101, and above described transmission belt 106 is provided with feed track base 102, and above described feed track base 102 is provided with feed track 104, and above described feed track 104 is provided with trough, in the trough The LED material is placed. In practice, the feed rail base 102 is provided with a feed confluence block 103 , and the feed confluence block 103 is provided with a feed rail. A material blocking structure 105 is provided on one side of the feeding track 104; during implementation, the trough is a clamping position arranged on the feeding track, and when the suction nozzle ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com