Clutch control with hysteresis consideration

A friction clutch and hysteresis technology, applied in clutches, mechanical equipment, etc., can solve problems such as friction and elastic effect hysteresis, achieve precise transmission and improve driving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

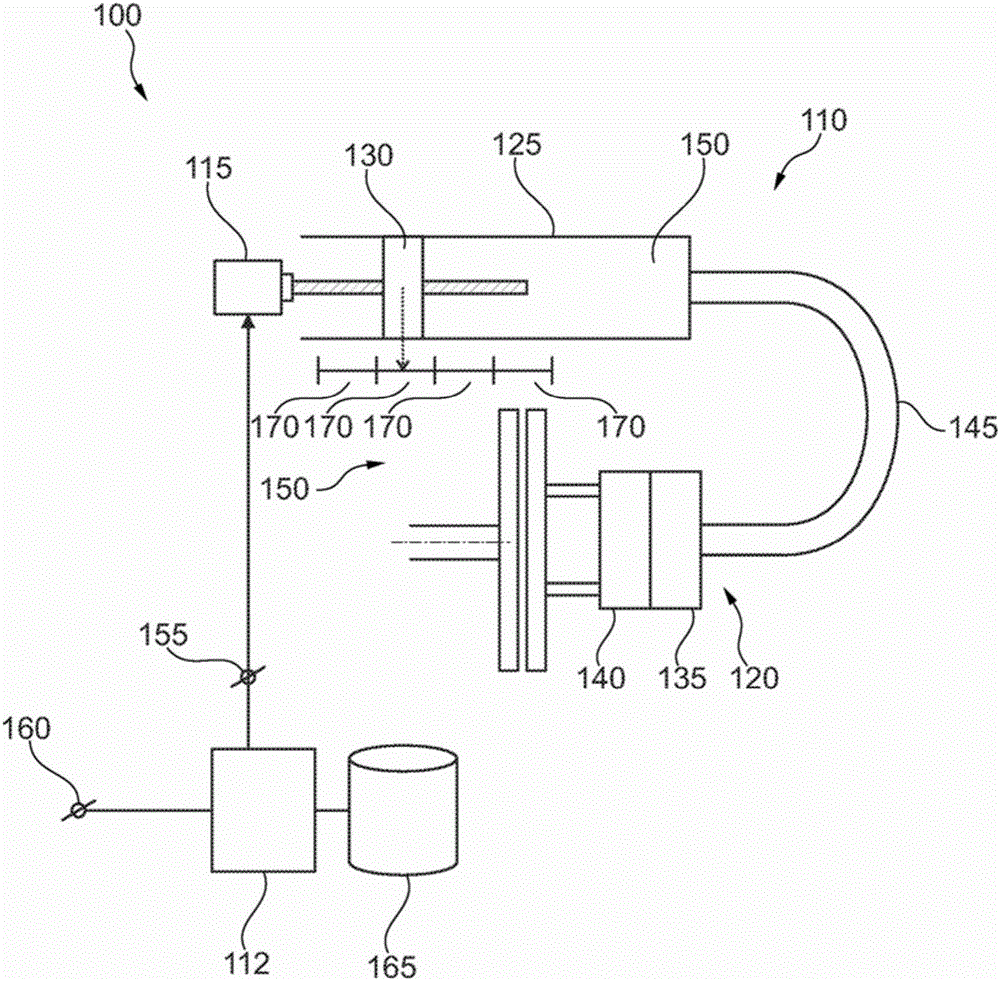

[0024] figure 1 A clutch system 100 is shown for use in a drive train, for example in a motor vehicle. The clutch system 100 includes a friction clutch 105 , an actuating device 110 and a control device 112 , which in the present embodiment are designed electrohydraulically. It is irrelevant for the consideration whether the torque transmittable via friction clutch 105 increases when the actuation by means of actuation device 110 is increased or decreased. Friction clutch 105 is especially capable of transmitting torque between the engine and the transmission. In one embodiment, friction clutch 105 is part of a dual clutch of a dual clutch transmission.

[0025] In the embodiment shown, the actuating device 110 can be controlled electrically. This is also a "clutch-by-wire" system if actuation is performed by means of an electro-sensitive clutch pedal. Actuating device 110 includes an electric actuator 115 and a hydrostatic line 120 . The hydrostatic line 120 includes a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com