Vibration flapping device for harvesting fruit without damage

A driving device and harvesting technology, which is applied in the direction of harvesters, pickers, agricultural machinery and implements, etc., can solve the problems of jujube trees not being able to achieve automatic harvesting, damage to fruit tree branches and root systems, and different crown shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

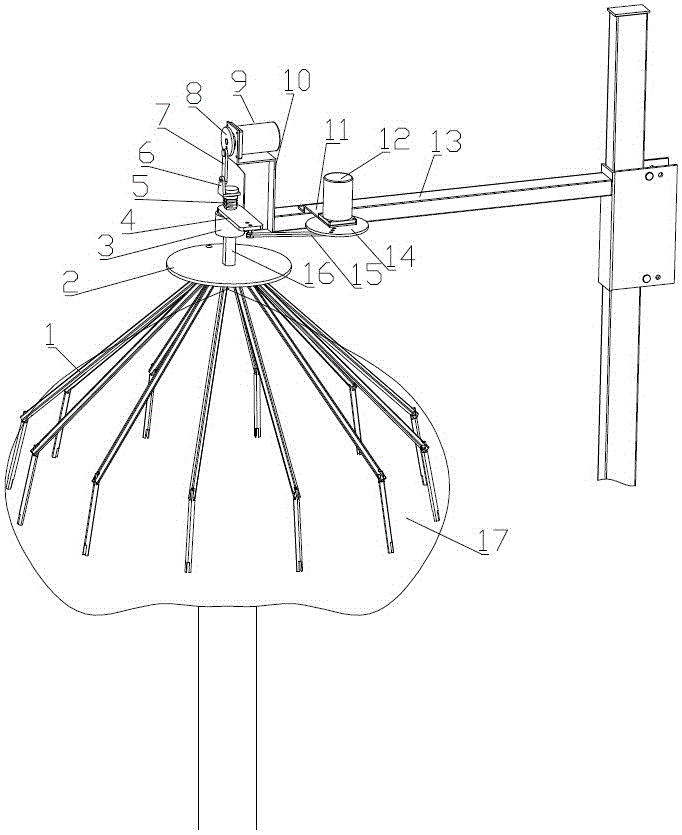

[0020] The plucking object of present embodiment is red jujube fruit tree 17, and the nondestructive fruit harvest vibration that adopts beats device such as figure 1 As shown, it includes a horizontal axis motor 9 and a vertical axis motor 12 arranged at the end of the support 13 through a vertical vibration mechanism base 10 and a circumferential vibration mechanism base 11 respectively. The output end of the horizontal axis motor 9 is equipped with a vertical eccentric wheel 8, the vertical eccentric wheel 8 is hinged with the upper end of the suspension ring 6 through the vertical connecting rod 7, and the lower end of the suspension ring 6 is connected with the upper end of the vertical guide shaft 16. A vertically oscillating crank-link mechanism. The guide shaft 16 is inserted in the guide ring 3 to form a vertical movement pair. The lower end of the guide shaft 16 is fixedly connected with the horizontal positioning plate 2. The bottom surface of the positioning plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com