Rotary type oil coater for end cover of motor

A motor end cover and rotary technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as uneven oiling, oil waste, and difficulty in ensuring the quality of oiling, so as to achieve uniform oiling and use Quantitatively stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

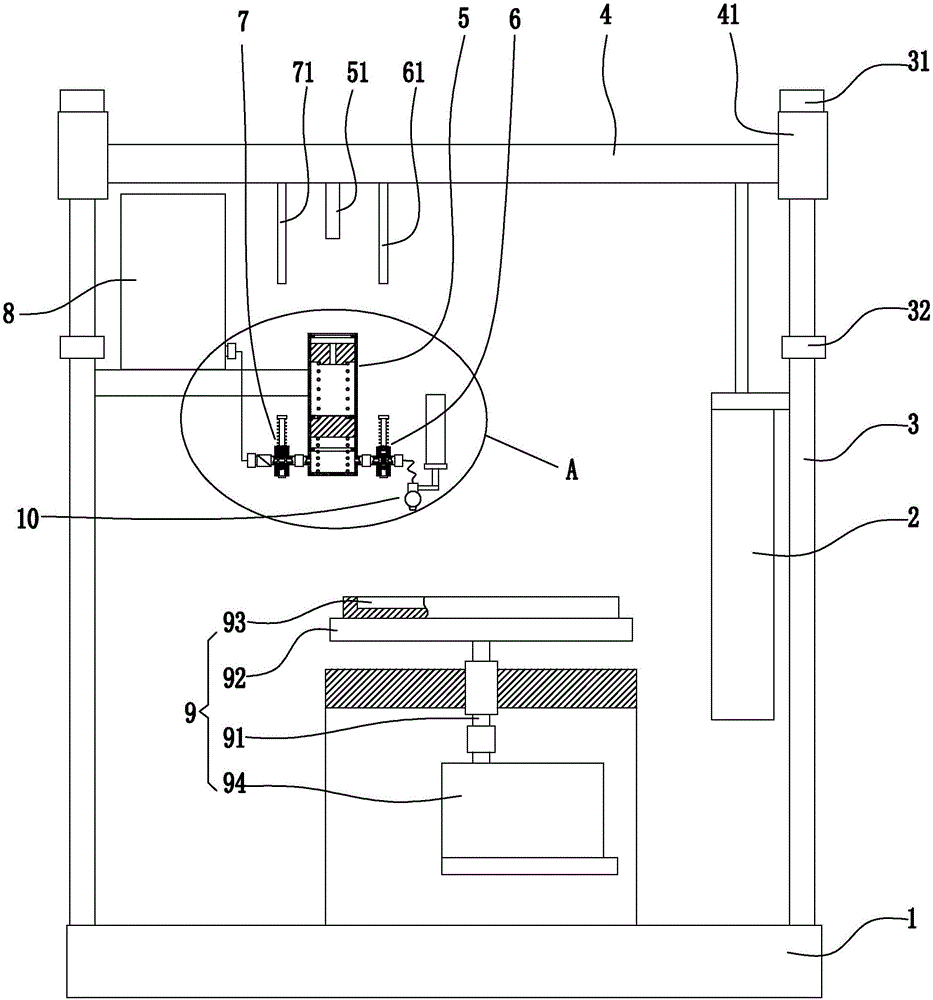

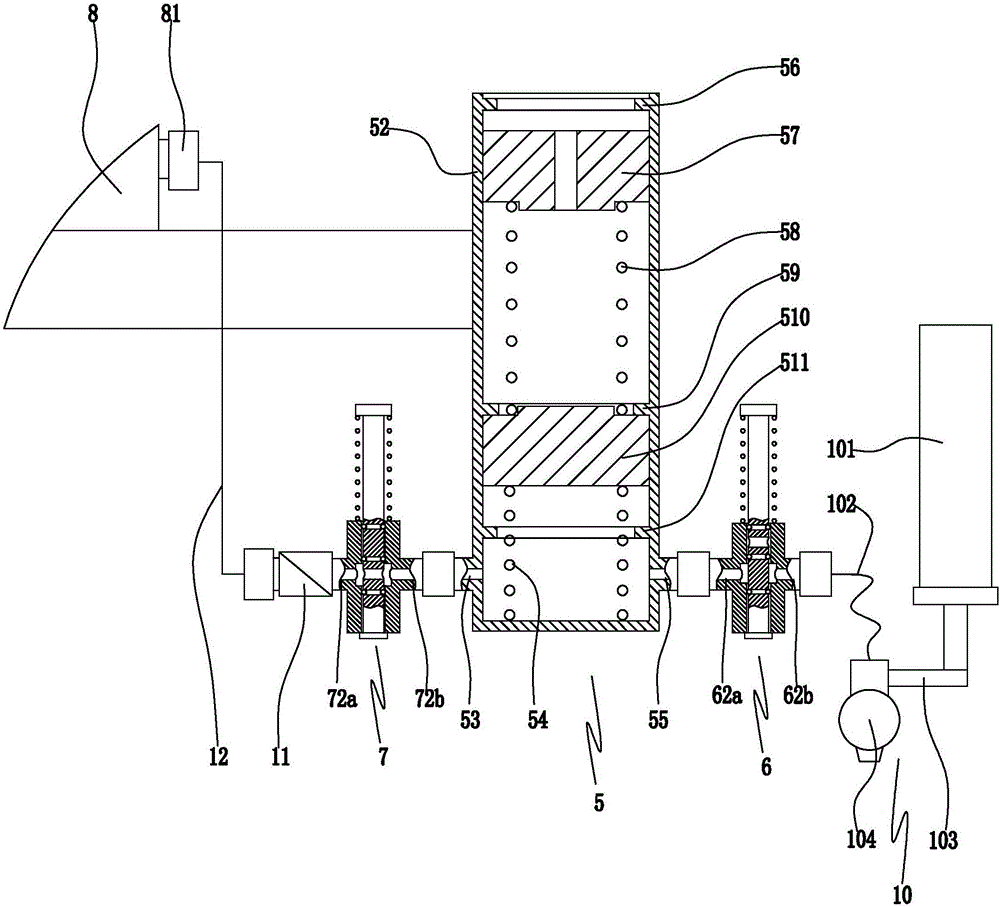

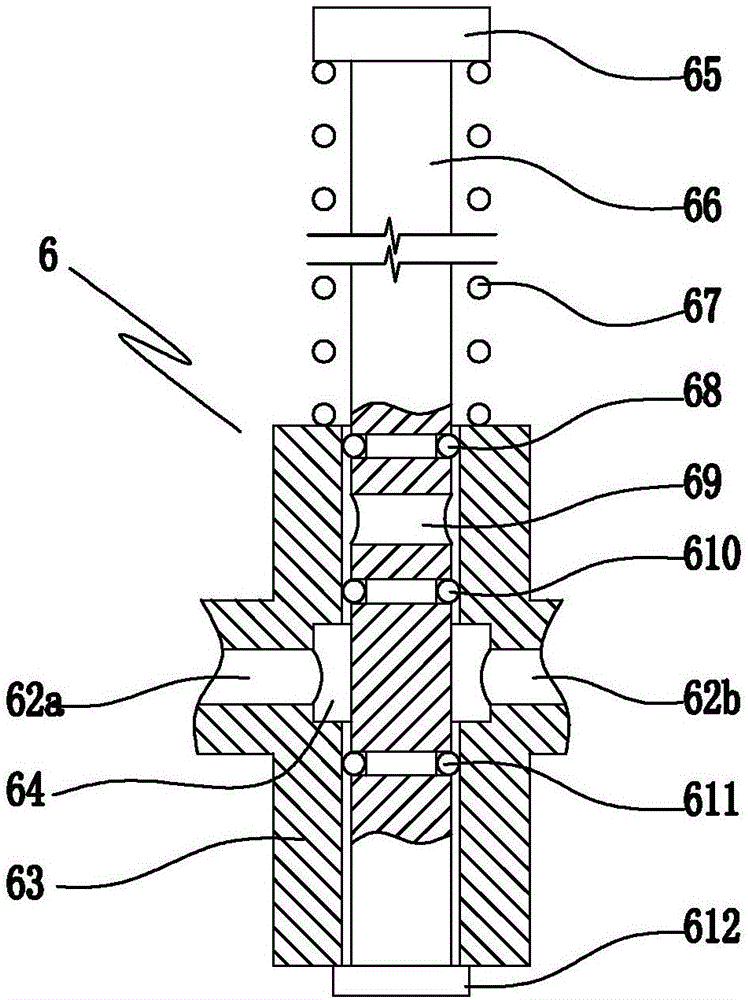

[0024] Such as figure 1 As shown, a rotary motor end cover oiler includes a fuel tank 8, a chassis 1, a vertical guide column 3 arranged on the chassis, an upper frame 4 that can be lifted and lowered along the vertical guide column, and a lifting mechanism for lifting the upper frame. Device 2, adaptive quantitative oiling device 5 and end cap rotation device 9. The vertical guide post is provided with a guide post upper limit block 31 and a guide post lower limit block 32 . The upper frame is provided with a guide sleeve 41 cooperating with the vertical guide post, and the guide sleeve is located between the upper limit block of the guide post and the lower limit block of the guide post. The lifting device is a lifting cylinder.

[0025] The end cap rotating device comprises an end cap placing plate 92 rotatably arranged on the underframe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com