Knurling tool and knurling system

A knurling knife and knurling technology are applied in the field of machining, which can solve the problems affecting the qualified rate and stability of patterns, and cannot achieve standardization, and achieve the effects of improving the qualification rate and stability, reducing the abnormal rate and reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

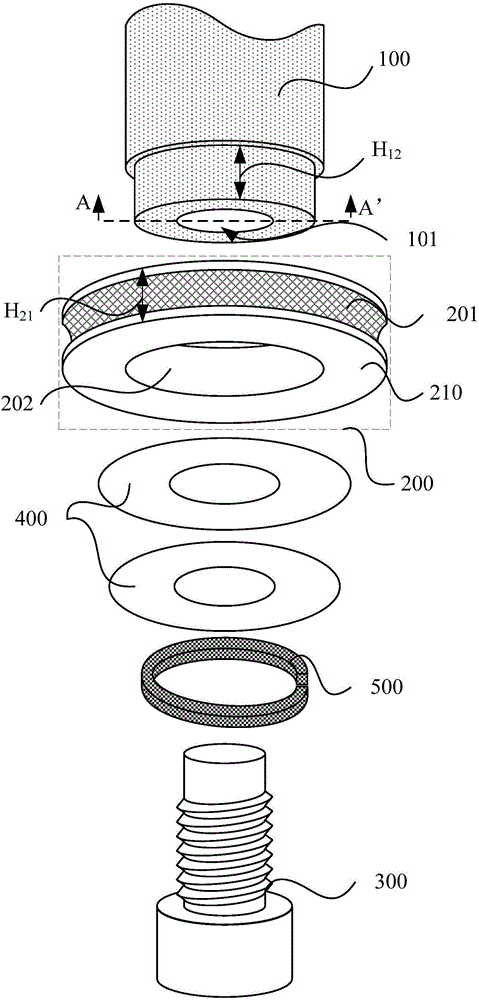

[0031] It can be seen from the background art that the manual knurling method used in the prior art to deal with the structural fracture of the ring cannot realize the standardization of knurling, and problems such as uneven knurling are prone to occur. Now in combination with the process analysis of the ring knurling process in the prior art, the reasons are as follows:

[0032] In the prior art, the knurling treatment of the structural fracture of the ring is basically realized by manual knurling. However, manual knurling cannot achieve the standardization of the knurling effect, and it is prone to shortcomings such as uneven patterns. Moreover, there are many manual knurling steps, and the process is complicated.

[0033] In addition, knurling technicians who perform manual knurling need a long period of study and practice before they can master the technology of manual knurling, which has a great impact on the improvement of production capacity.

[0034] In order to solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com