Locating fixture for realizing coaxial assembling of two pipelines

A positioning tooling and coaxial technology, applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of poor sealing performance and tensile strength, to prevent pipe displacement and deformation, product sealing performance and anti-corrosion Good tensile strength and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

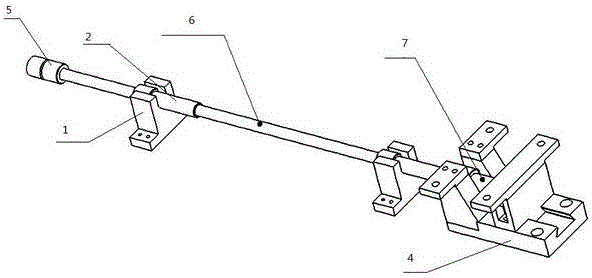

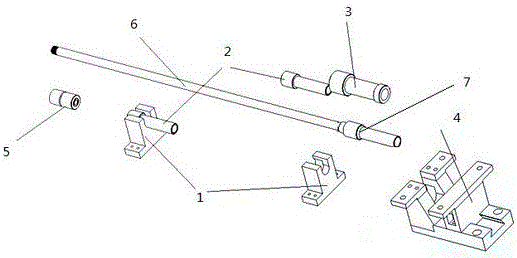

[0048] Such as figure 1 and figure 2 As shown, this embodiment provides a positioning tool for the coaxial assembly of two pipelines. The tooling includes a positioning frame 1, a positioning sleeve 2, a sleeve 3 and a positioning mold 4. The positioning sleeve 2 is assembled on the positioning frame 1. A positioning frame 1 is equipped with a positioning sleeve 2, and the sleeve 3 is assembled on the positioning mold 4. After assembly, the axes of the positioning sleeve 2 and the sleeve 3 are on the same straight line.

[0049] The positioning tool also includes a tailstock positioning sleeve 5 .

[0050] The tailstock positioning sleeve 5 is a stepped shaft, and the interior of the stepped shaft is hollow.

[0051] The positioning frame 1 is provided with a positioning sleeve groove 10 , and the positioning sleeve 2 is assembled in the positioning sleeve groove 10 .

[0052] Such as Figure 4 and Figure 5 As shown, the positioning sleeve 2 is a stepped shaft, and the ...

Embodiment 2

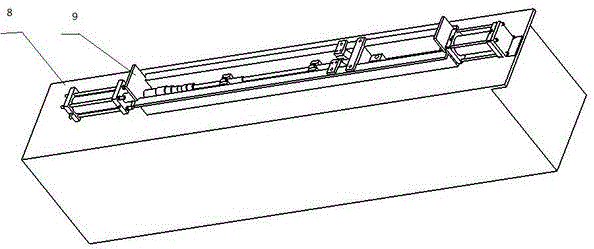

[0073] This embodiment is basically the same as Embodiment 1, except that the positioning sleeve and the positioning frame are fixedly connected together, and the positioning sleeve can be directly integrally formed with the positioning frame, or the positioning sleeve can be directly welded on the positioning frame. The sleeve and the fixing frame are fixedly connected together, and the sleeve can be directly integrally formed with the fixing frame, or can be directly welded on the fixing frame. As for the number of positioning sleeves and positioning frames, it is determined according to the length of the pipe, as long as the pipe can be well supported to prevent the pipe from bending and deforming during extrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com