Novel tool changing structure for tool magazine

A tool magazine, a new type of technology, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of high failure rate of mechanical and electrical parts, difficult long-term guarantee of tool change accuracy, high production cost, etc., to achieve fast and safe tool replacement, reduce The effect of tool change misoperation and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

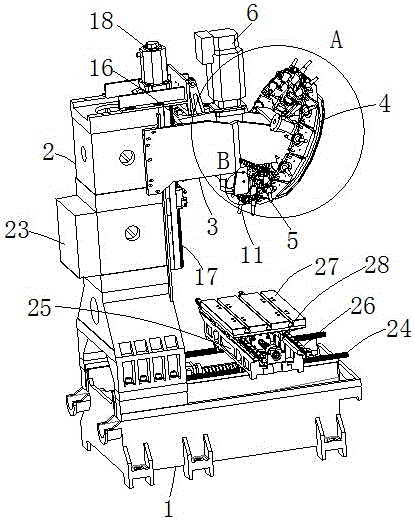

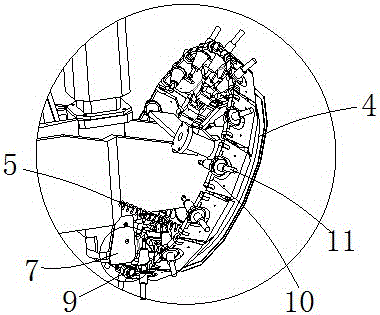

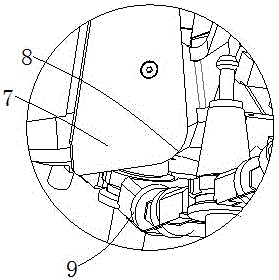

[0017] Such as Figure 1 to Figure 5 As shown, a new type of tool magazine tool change structure, including a base 1 and a host column 2 connected to the base 1, the host column 2 is connected to the tool magazine bracket 3, and the end of the tool magazine bracket 3 is movably connected to the tool magazine rotating seat 4, The tool magazine revolving seat 4 is connected with the tool magazine support 3 through the tension spring 5, and the main shaft 6 is arranged on one side of the host column 2, and the main shaft 6 is connected with the host column 2 through the lifting control mechanism, and the free end of the main shaft 6 is connected with the gripping plate 7 , Grab knife pressing plate 7 is provided with protruding arc surface 8, is provided with a plurality of equidistant notches on the knife storehouse rotating seat 4, is provided with knife storehouse roller 9 in the notch, and the arc shape of grasping knife press plate 7 The surface 8 corresponds to the peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com