Internal swelling reverse hooking mechanism for turbocharging exhaust manifold and turbine casing

A technology for exhaust manifolds and turbocharging, applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of poor positioning effect and low machining accuracy of parts, and achieve the effect of improving positioning and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

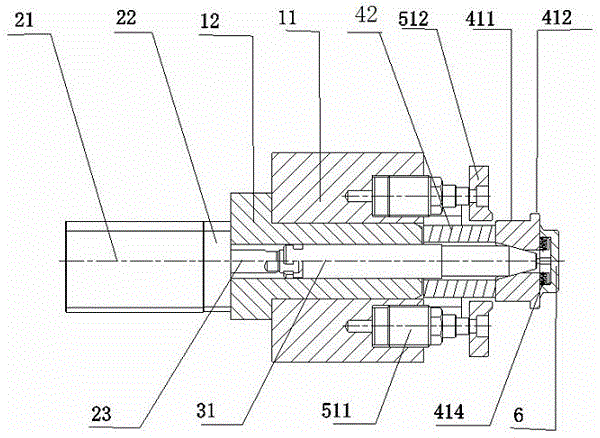

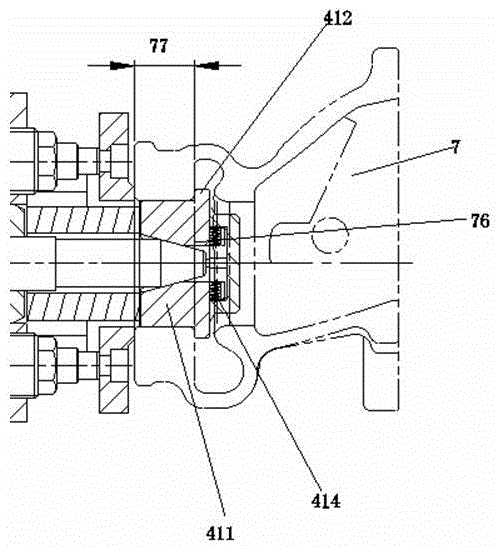

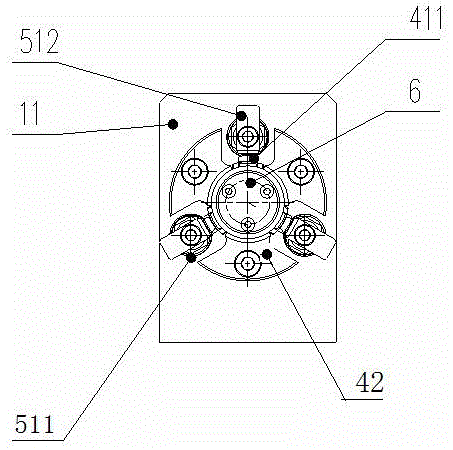

[0021] Combine below Figure 1 to Figure 6 The connection mode and specific implementation of the present invention will be described, but the present invention is not limited to the following connection mode and specific implementation.

[0022] An internal expansion anti-hook mechanism for turbocharged exhaust manifolds and turbine casings, including a seat device, a first hydraulic device, a transmission device in a sleeve, a positioning claw device, and a second hydraulic device. The sleeve One end of the inner transmission device is connected to the positioning claw device, and the other end is connected to the first hydraulic device after passing through the base device; the second hydraulic device is installed on the base device, and the propelling end of the second hydraulic device is located between the base body and the positioning claw device between.

[0023] The seat device includes a seat body 11 and a guide sleeve 12; the first hydraulic device includes an oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com