Intelligent moving line edge bin applicable to SMT (surface mount technology)

A mobile line, intelligent technology, applied in the field of online side warehouse, can solve the problems of low work efficiency, waste of manpower and material resources, waste of working time, etc., to achieve the effect of reasonable layout, saving space, and satisfying the picking and placing of a large number of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

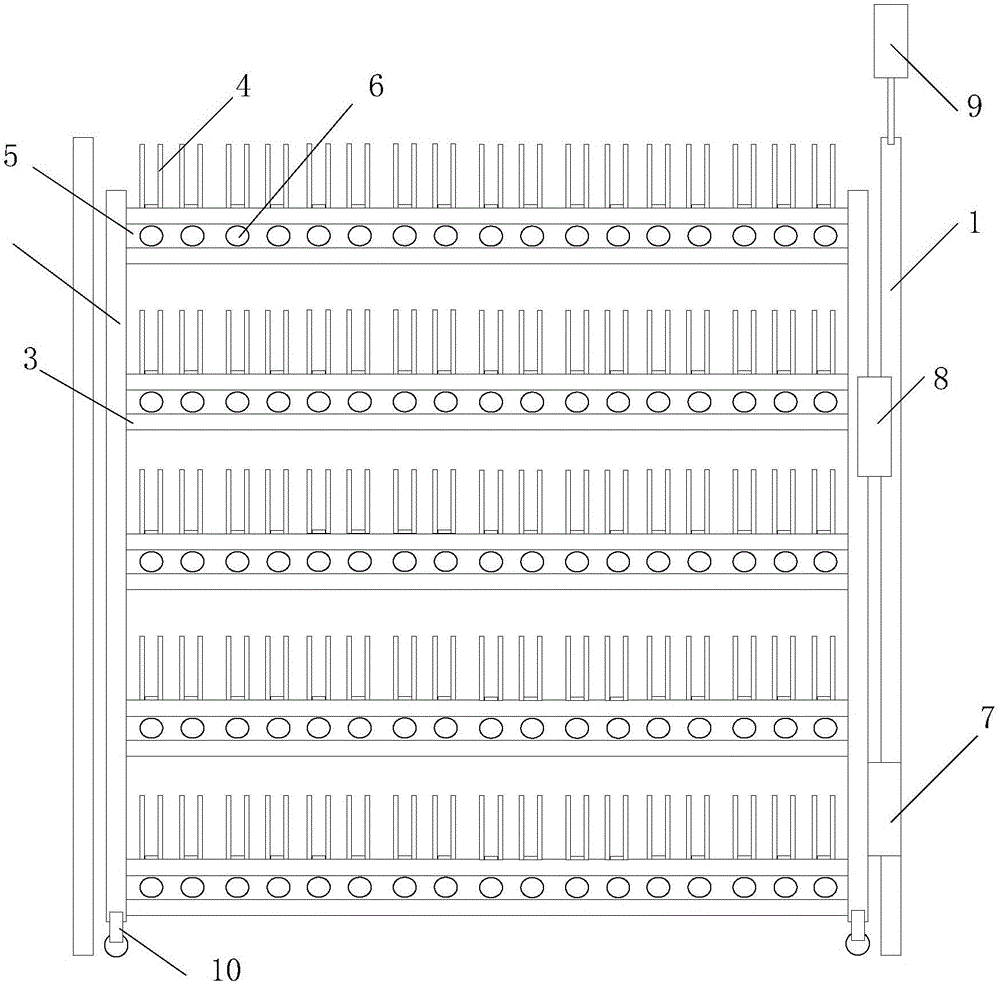

[0020] Example: such as figure 1 The shown intelligent mobile line side warehouse suitable for SMT includes a peripheral bracket 1, and a material rack 2 is arranged inside the peripheral bracket 1. A number of material levels are distributed on the plate 3, and a number of bearing brackets 4 are arranged on the material levels. At the same time, a marking device is provided at the front end of the laminate 3 , and a material sensing device is provided on the material level or the supporting bracket 4 . Moreover, considering the daily power supply needs of each device to meet stable work, an energy supply device 7 is provided on the material rack 2, and the energy supply device 7 is connected to the identification device and the material sensing device. Displacement device 10.

[0021] In view of a preferred embodiment of the present invention, several bearing brackets 4 are equidistantly distributed, and the bearing brackets 4 are rectangular brackets or elliptical brackets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com