Wood and plastic co-extruded door pocket adjusting plate extrusion die

A technology of extrusion die and adjustment plate, applied in the field of extrusion die, can solve the problems of consuming a lot of wood resources, easy to be deformed by moisture, poor safety, etc., and achieve the effect of reducing cost, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

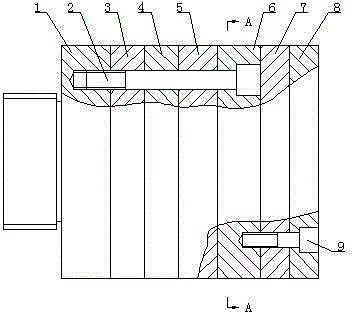

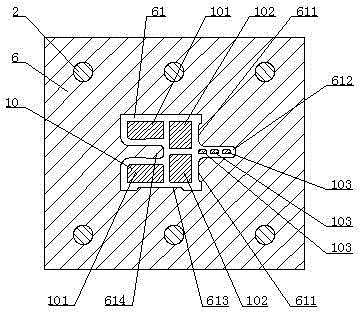

[0008] see Figure 1 to Figure 2 , the present invention includes a die head 1, a long screw 2, a transition plate 3, a support plate 4, a manifold 5, a mouth template 6, a cooling water jacket 7, a cooling water jacket 2 8, a short screw 9 and a mandrel group 10. The middle part of the mouth template 6 is provided with a die hole 61, and on the right side of the die hole 61, two leftward protrusions 611 symmetrical up and down are arranged, and on the right side of the die hole 61, The middle part of the side is provided with a horizontal groove 612, the middle part of the lower side of the die hole 61 is provided with a wide boss 613, and the middle part of the left side of the die hole 61 is provided with a horizontal groove 612. Groove 612 is adapted to the right protrusion 614. The mandrel set 10 includes two rectangular mandrels I101, two rectangular mandrels II102 and three small rectangular mandrels 103. The mandrel set 10 is mounted on On the support plate 4, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com