Gilding plate, gilding press and gilding method

A bronzing plate, bronzing machine technology, applied in bronzing plate, bronzing machine and bronzing field, can solve the problems of lower product qualification rate, rubbing of bronzing part, temperature difference of holographic bronzing, etc., to improve production efficiency and ensure the effect of quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

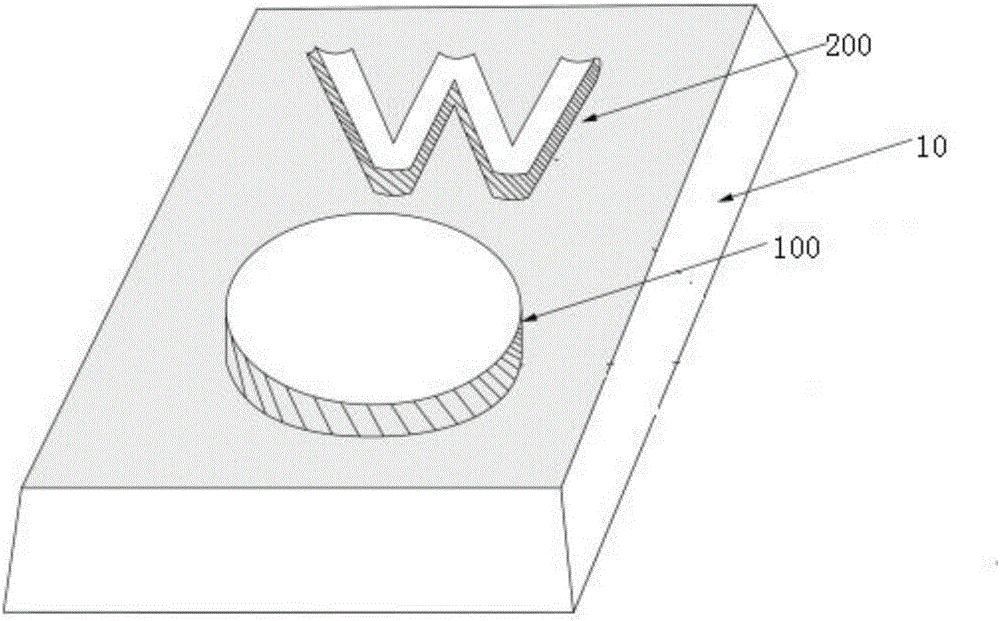

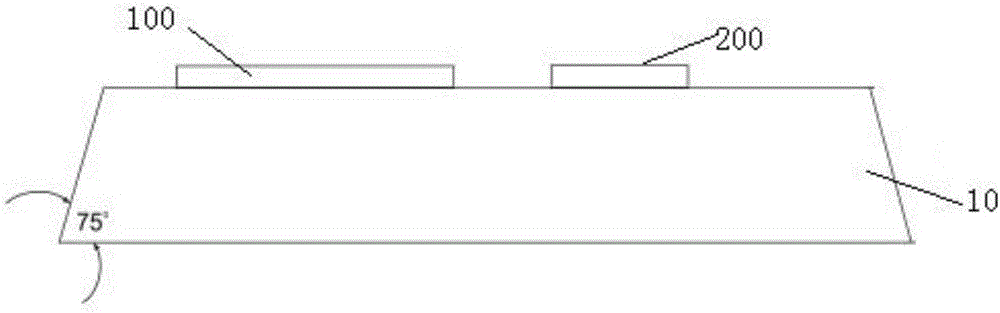

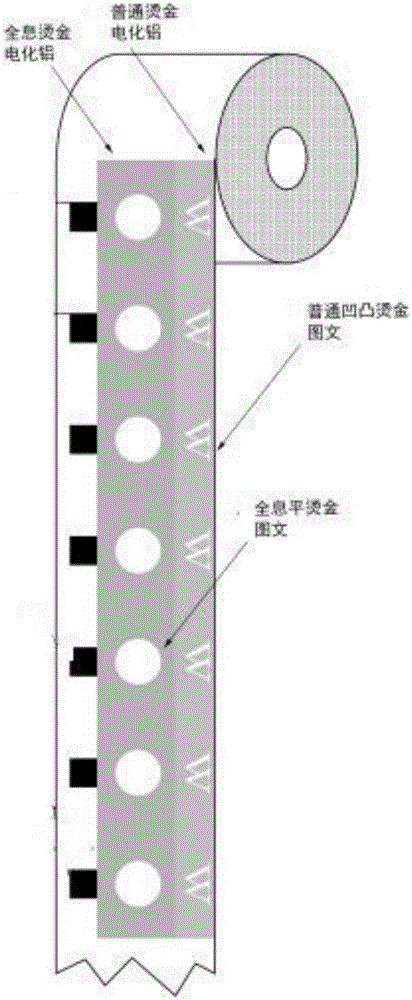

[0039] Such as Figure 1-2 As shown, the hot stamping plate of the present invention includes a plate base 10, on which a holographic hot stamping area 100 and a concave-convex hot stamping area 200 are protrudingly arranged, and between the holographic hot stamping area 100 and the concave-convex hot stamping area 200 The spacing distance is less than or equal to 25mm. More specifically, the holographic hot stamping area 100 and the concave-convex hot stamping area 200 are all carved on the 8mm thick copper plate base by an electric engraving machine. Keep the thickness of the pattern part unchanged at 8mm, and use an electric engraving machine to carve out the parts that do not need hot stamping. At the same time, when engraving, the center of the holographic hot stamping area 100 is raised to form a pot-bottom-like surface, that is, the center is high and the surrounding is low. Concave-convex bronzing area 200 is to engrave and form a downward concave pattern on its surfac...

Embodiment 2

[0044] Such as Figure 4 As shown, the bronzing machine of the present invention includes a paper feeding table 1, a paper feeding table 2 connected with the paper feeding table 1, a positioning pull gauge 3 arranged above the end of the paper feeding table 2, and under the action of the positioning pull gauge 3 , can position the paper surface on the paper feeding table 2; the positioning front gauge 4 arranged at the end of the paper feeding table 2, under the action of the positioning front gauge 4, can position the paper laterally; that is to say, before positioning Under the synergistic effect of the gauge 4 and the positioning pull gauge 3, the paper has a precise and fixed conveying position, which is fully prepared for the subsequent bronzing process; The hot stamping plate above as described in embodiment 1, is installed with the hot stamping plate, is used for the honeycomb version 6 that heats the hot stamping plate, is arranged on the paper gripper bar 7 between th...

Embodiment 3

[0047] Present embodiment is the bronzing method that utilizes the bronzing machine in embodiment 2 to carry out bronzing, and this bronzing method specifically comprises the following steps:

[0048] S1, the installation of hot stamping version

[0049] The hot stamping plate is firmly locked on the honeycomb plate by the self-locking device, and a corresponding number of hot stamping plates are installed according to the needs of the hot stamping pattern;

[0050] S2. Installation of cellular version

[0051] Install the honeycomb version with the hot stamping version at the installation position of the honeycomb version of the hot stamping machine, and lock it;

[0052] S3, installation of anodized aluminum

[0053] Place the anodized aluminum in the anodized aluminum unwinding device. When placing the anodized aluminum, you must pay attention to the direction of the hot stamping of the anodized aluminum to be consistent with the direction of the hot stamping version, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com