Parallel type express packing robot

A parallel and robotic technology, applied in the field of robotics, can solve problems such as repetitive operations, time-consuming, labor-intensive, and time-wasting problems, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

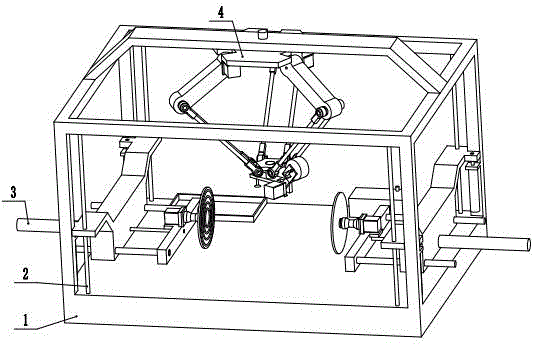

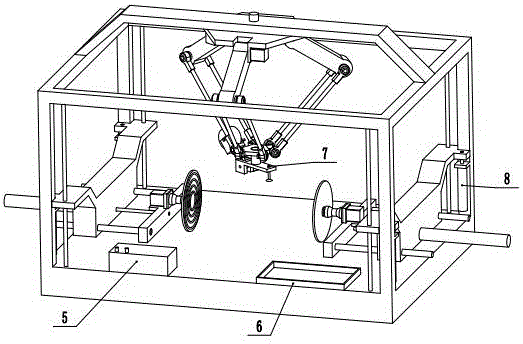

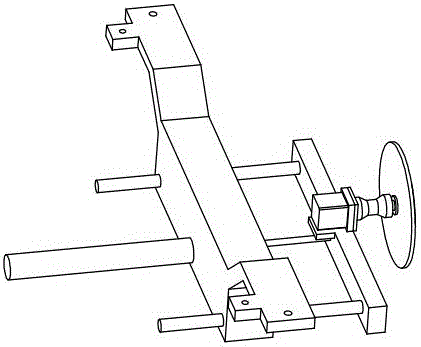

[0017] Such as Figure 1 to Figure 6 As shown, a parallel express packaging robot includes a frame 1, four first guide shafts 2, two sets of lifting and turning function modules 3, an action function module 4, a vacuum pump 5, a label box 6, an execution function module 7, a second An electric cylinder 8, the bottom of the frame 1 is a cuboid structure with four square columns at the four corners, four beams above, a curved beam between the left and right beams, and a round through hole in the middle of the beam ; The left and right sides of the front and back sides of the frame 1 respectively have a pair of round holes; the four first guide shafts 2 are placed vertically, and are respectively fixedly installed at the round holes at the four corners of the frame 1; Two groups of lifting and turning functional modules 3 are distributed on both sides of the frame 1, and are respectively slidably installed between the first guide shafts 2 on both sides through the round holes on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com