Lifting device for cooling tower steel structure construction and using method thereof

A technology for cooling towers and steel structures, applied in transportation and packaging, traveling bridge cranes, load suspension components, etc., can solve problems such as poor assembly accuracy, inapplicable lifting devices, and high construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further illustrated below by specific examples.

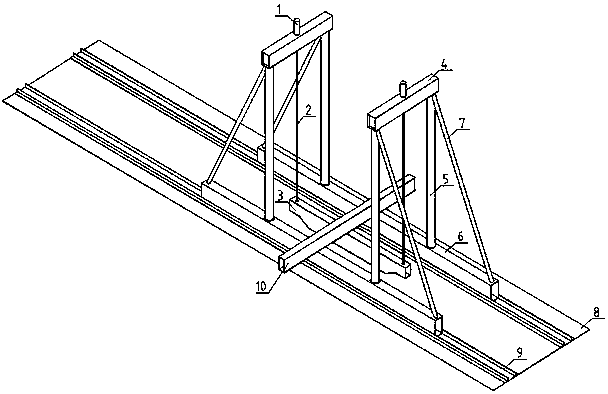

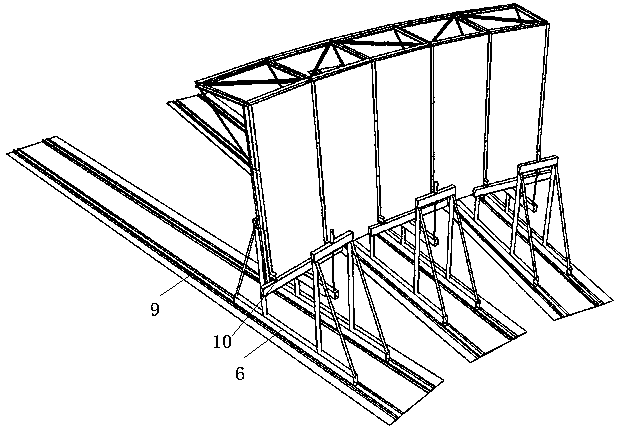

[0022] Such as figure 1 As shown, a lifting device for cooling tower steel structure construction includes a base plate 8, a guide rail 9, a support, a lifting device and a bracket; the guide rail 9 is laid on the base plate 8, and the support is arranged on the guide rail 9 and can be Slide back and forth along the guide rail 9, and the lifting device is arranged on the support. The lifting device includes a lifter 1 arranged on the support and a connecting steel cable 2 connected with the lifter 1 and the bracket respectively, and the steel structure module of the cooling tower After the ground is built, it is placed on the bracket and lifted by the lifter 1 for subsequent hoisting operations.

[0023] The lifting device for cooling tower steel structure construction, the bracket is a frame structure, which includes two bottom beams 6, diagonal braces 7, columns 5 and top beams 4 arranged in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com