Material cleaner for shaping furnace

A cleaning device and a technology for shaping furnaces, applied in glass furnace equipment, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of clogging in the furnace, difficult to clean, high hardness of solid glass blocks, etc., and achieve high cleaning efficiency. , the effect of easy dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

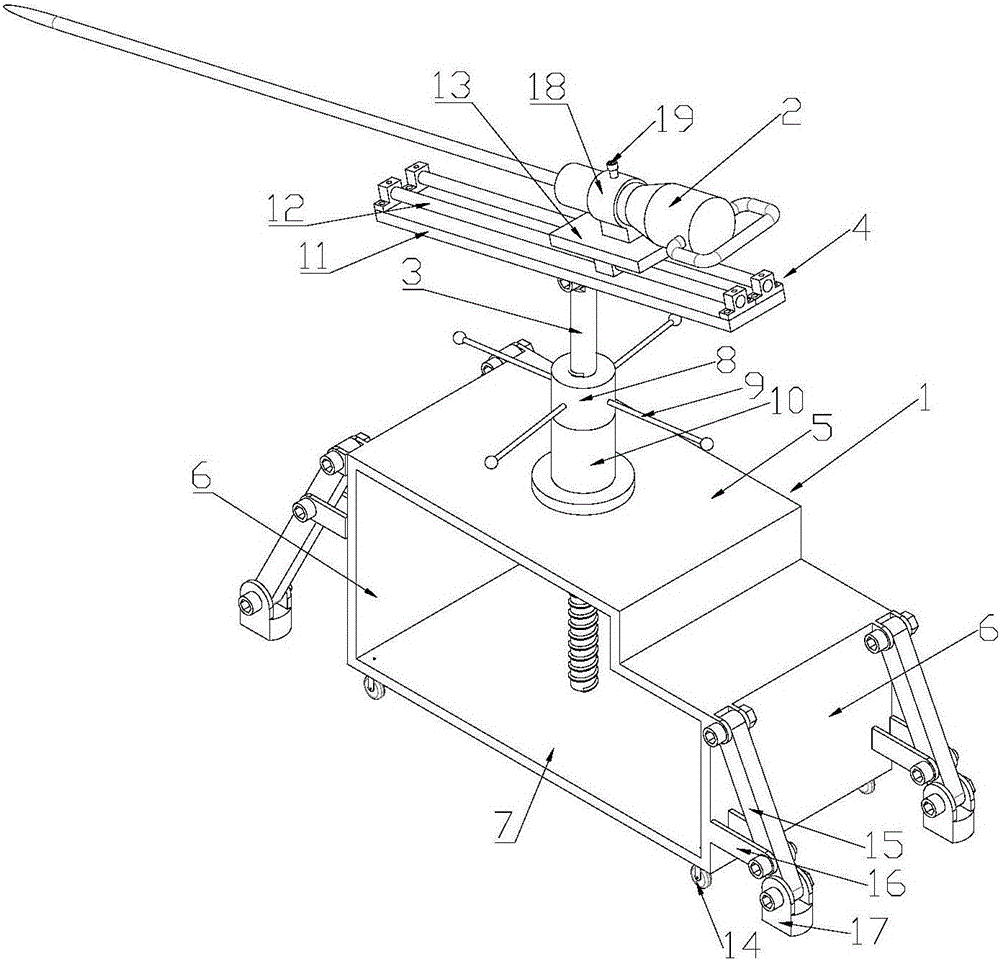

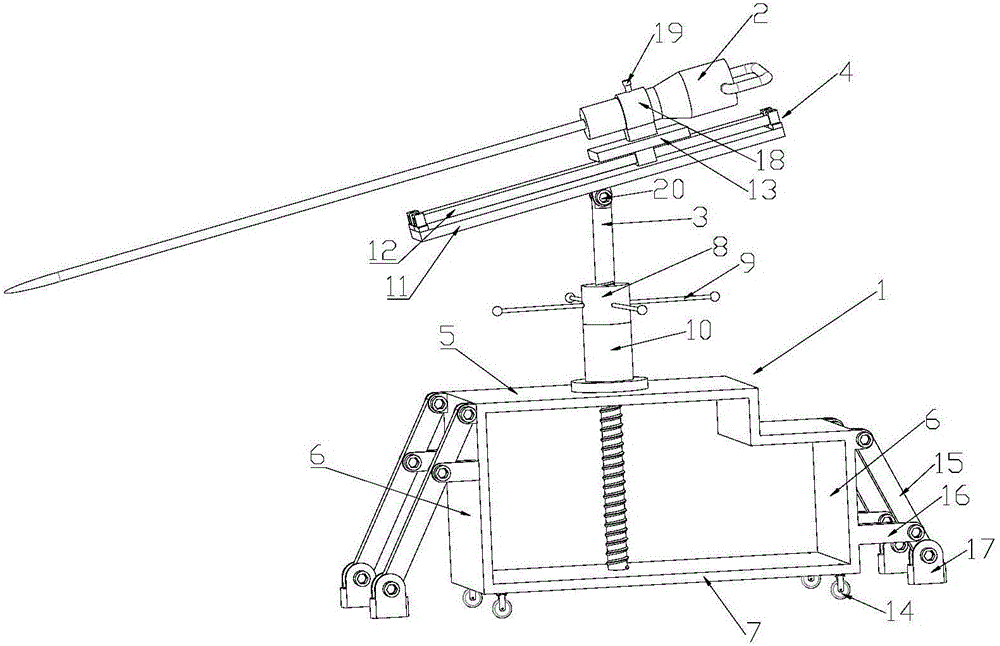

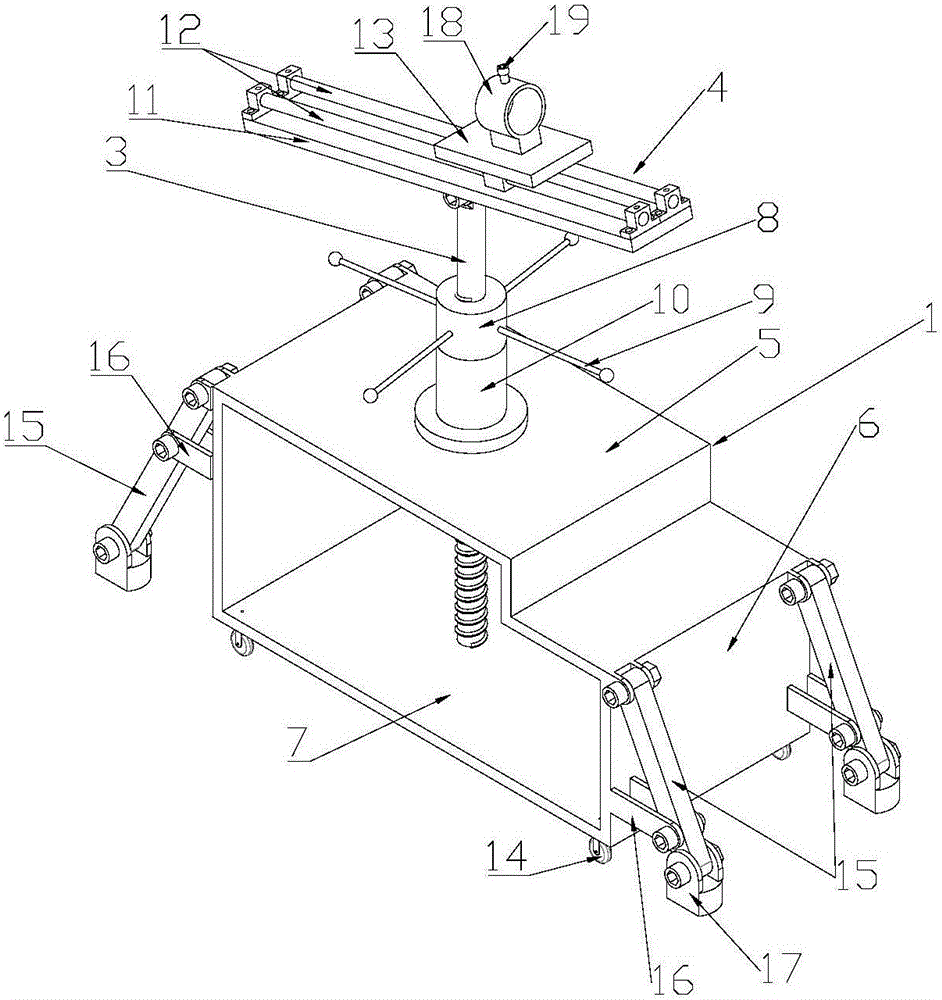

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0040] The invention provides a material cleaning device for a shaping furnace, which includes a movable frame 1, a lifting adjustment mechanism and a dredging mechanism 4, and the dredging mechanism 4 is arranged on the frame 1 through the lifting adjusting mechanism to be able to Lifting and lowering relative to the vehicle frame 1, the dredging mechanism 4 has a dredging tool 2 capable of reciprocating movement along at least one direction relative to the lifting adjustment mechanism, for dredging the materials in the shaping furnace. Through the above structure, that is, the dredging mechanism 4 is lifted relative to the vehicle frame 1 through the lifting a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap