Polylactic acid composition with ductility and impact toughness and preparation method thereof

A technology of impact toughness and polylactic acid, which is applied in the field of polylactic acid composition with both ductility and impact toughness and its preparation, can solve the problem of material strength decline, elongation at break, low impact strength, and inability to toughen or plasticize and other problems, to achieve the effect of increasing impact toughness and ductility, improving interfacial cohesion, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

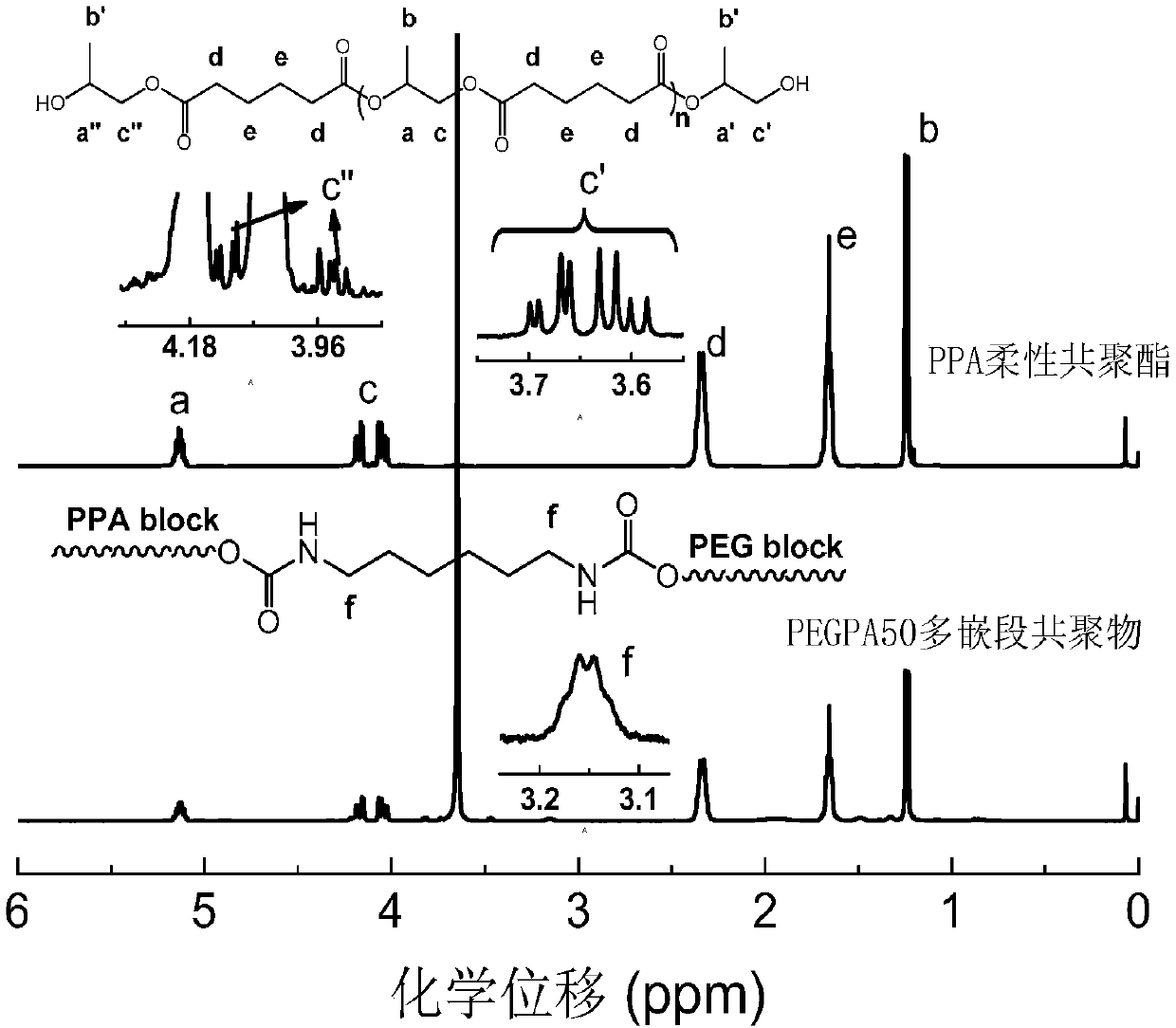

[0049] Synthesis of hydroxyl-terminated flexible polyester prepolymer PPA:

[0050] Add 1,2-propanediol and adipic acid, the molar ratio of 1,2-propanediol and adipic acid is 1.2:1, stir the above reaction system at 160°C until the solution becomes clear, then add the catalyst n-butyl titanate, Add n-butyl titanate in an amount of 0.1% of the molar amount of adipic acid, raise the temperature to 170°C, carry out the esterification reaction under a nitrogen atmosphere, raise the temperature by 10°C every 1 to 3 hours, and control the maximum esterification temperature to 190°C , until the end of the esterification reaction when there is no distillate.

[0051] The reaction system was evacuated, and the temperature was raised to 200° C. for polycondensation reaction. After 10 hours of reaction, a hydroxyl-terminated flexible polyester prepolymer PPA was obtained.

[0052] After testing, the hydroxyl-terminated flexible polyester prepolymer PPA has a number-average molecular wei...

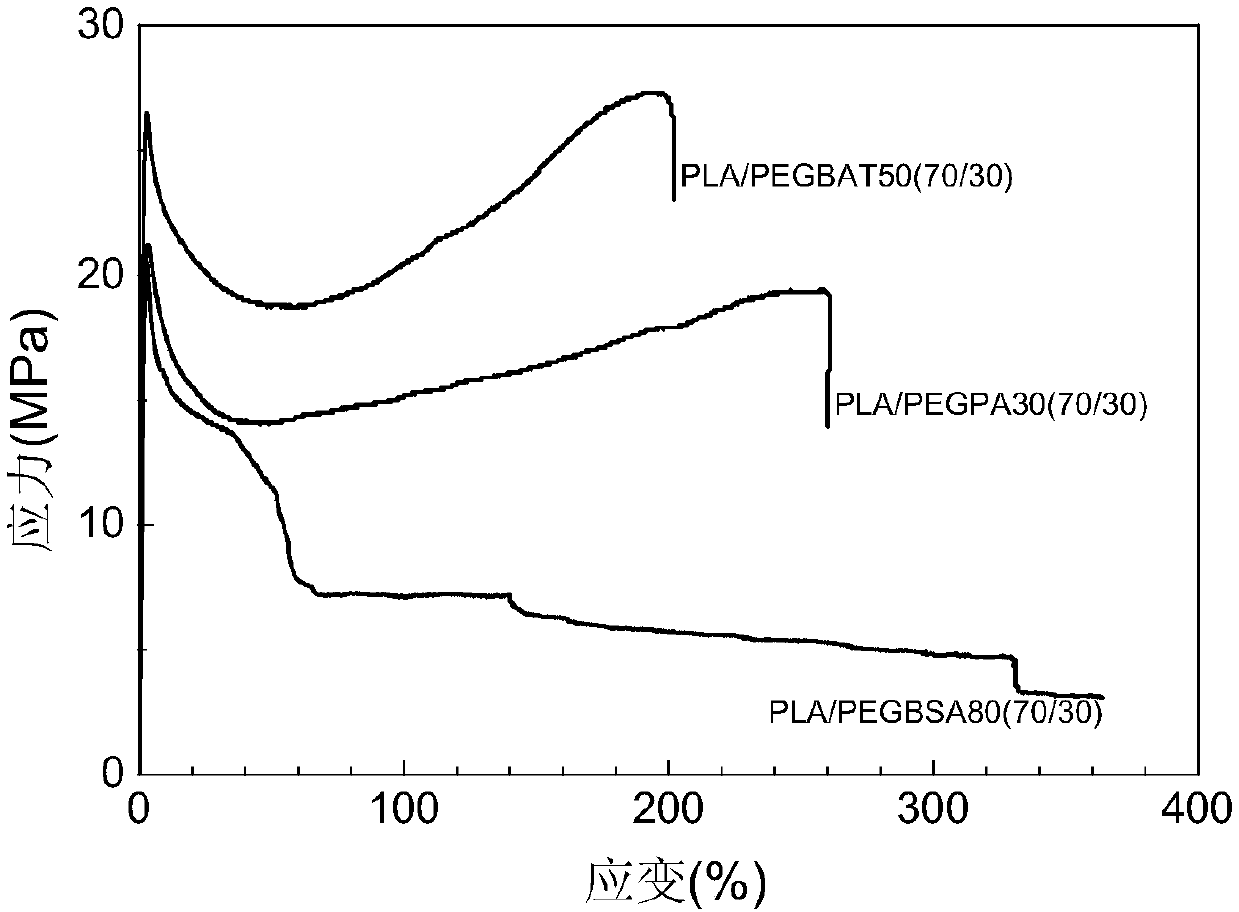

Embodiment 2

[0055] Synthesis of hydroxyl-terminated flexible polyester prepolymer PBAT:

[0056]Add butanediol, terephthalic acid and adipic acid, wherein the molar ratio of terephthalic acid and adipic acid is 45:55, and the alkyd molar ratio in the reaction system is 2:1, and stir the above reaction system at 170°C After 30 minutes, add the catalyst n-butyl titanate, the amount of n-butyl titanate added is 0.1% of the molar amount of dibasic acid, raise the temperature to 180°C, carry out the esterification reaction under nitrogen atmosphere, and raise the temperature by 10°C every 1-3h ℃, and control the maximum esterification temperature to be 200 ℃ until the reaction solution is completely clear and transparent to end the esterification reaction.

[0057] The reaction system was evacuated, and the temperature was raised to 210° C. for polycondensation reaction. After 12 hours of reaction, a hydroxyl-terminated flexible polyester prepolymer PBAT was obtained.

[0058] After testing, ...

Embodiment 3

[0060] Synthesis of hydroxyl-terminated flexible polyester prepolymer PBSA:

[0061] Add butanediol, succinic acid and adipic acid, wherein the molar ratio of succinic acid to adipic acid is 40:60, and the molar ratio of alkyd to acid in the reaction system is 1.2:1, and the above reaction system is stirred at 170°C until complete After clarification and transparency, add the catalyst n-butyl titanate, the amount of n-butyl titanate added is 0.1% of the molar amount of the dibasic acid, and the temperature is raised to 180°C, and the esterification reaction is carried out under a nitrogen atmosphere, and the temperature is raised every 1 to 3 hours 10°C, and control the maximum esterification temperature to 200°C until the reaction solution is completely clear and transparent to end the esterification reaction.

[0062] The reaction system was evacuated, and the temperature was raised to 210° C. for polycondensation reaction. After 12 hours of reaction, a hydroxyl-terminated f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com