Conversion type friction pendulous shock absorption and isolation support

A seismic isolation bearing and conversion technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of poor seismic performance of the bearing, reciprocating lifting, and shortening the service life of the spherical wear plate of the bearing, so as to achieve the anti-seismic effect. better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

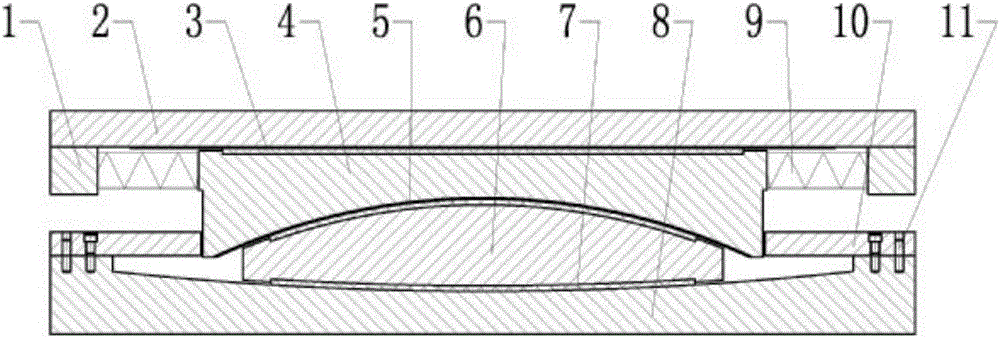

[0021] like figure 1 As shown, a convertible friction pendulum shock-absorbing shock-isolation bearing includes a hyperboloid body 6, and the upper and lower curved surfaces of the hyperboloid body 6 are respectively connected with a spherical wear-resistant slide plate I5 and a spherical wear-resistant slide plate II7, The upper and lower sides of the hyperboloid body 6 are respectively provided with an upper pendulum 4 and a lower pendulum 8, the upper surface of the upper pendulum 4 is connected with a plane wear-resistant slide plate 3, and a plane steel plate 2 is arranged above the upper pendulum 4. The end of the flat steel plate 2 is provided with a steel baffle plate 1 set downwards, and the hem 8 is provided with a steel baffle ring 10 for locking the upper pendulum 4, and the steel baffle ring 10 is fixed on the hem through a shear pin 11. 8, an elastic body 9 is also provided between the upper pendulum 4 and the steel baffle 1.

[0022] In this embodiment, the com...

Embodiment 2

[0025] On the basis of a conversion type friction pendulum shock-absorbing shock-isolation support described in Example 1, the spherical wear-resistant sliding plate I5 and the spherical wear-resistant sliding plate II7 are respectively inlaid on the upper and lower sides of the hyperboloid body 6. On the first curved surface, the plane wear-resistant slide plate 3 is inlaid on the upper surface of the upper pendulum 4. The setting of this embodiment makes the moving surface smoother, and the sealing performance is good when connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com