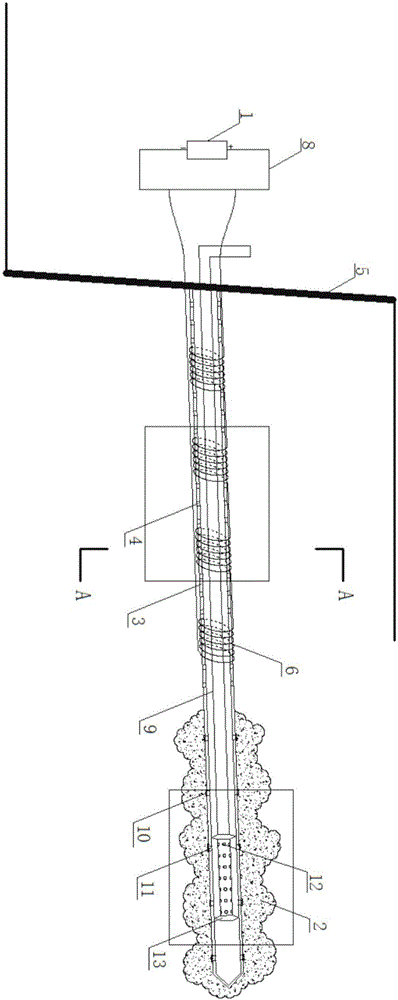

Sleeve-valve-pipe grouting and draining soil-nailing retaining device and construction method thereof

A sleeve valve pipe grouting and construction method technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of reduced drainage effect and low permeability of drainage soil nails, achieve good drainage effect and improve tensile strength Performance, the effect of unimpeded drainage channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A construction method of a sleeve valve pipe grouting drainage soil nail support device, comprising the following steps:

[0055] 1) Investigate and analyze the geological conditions of the slope, conduct engineering geological exploration and design, analyze and determine the design length and diameter of soil nails.

[0056] 2) According to the design length and diameter, make the steel sleeve valve tube 3 in advance:

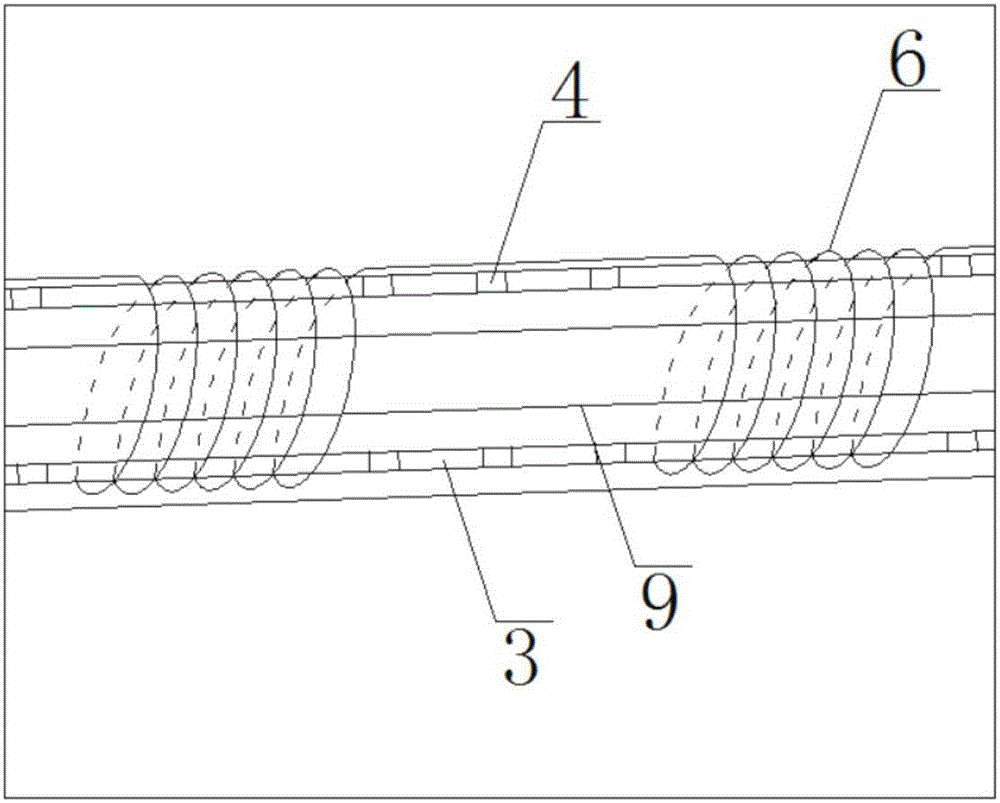

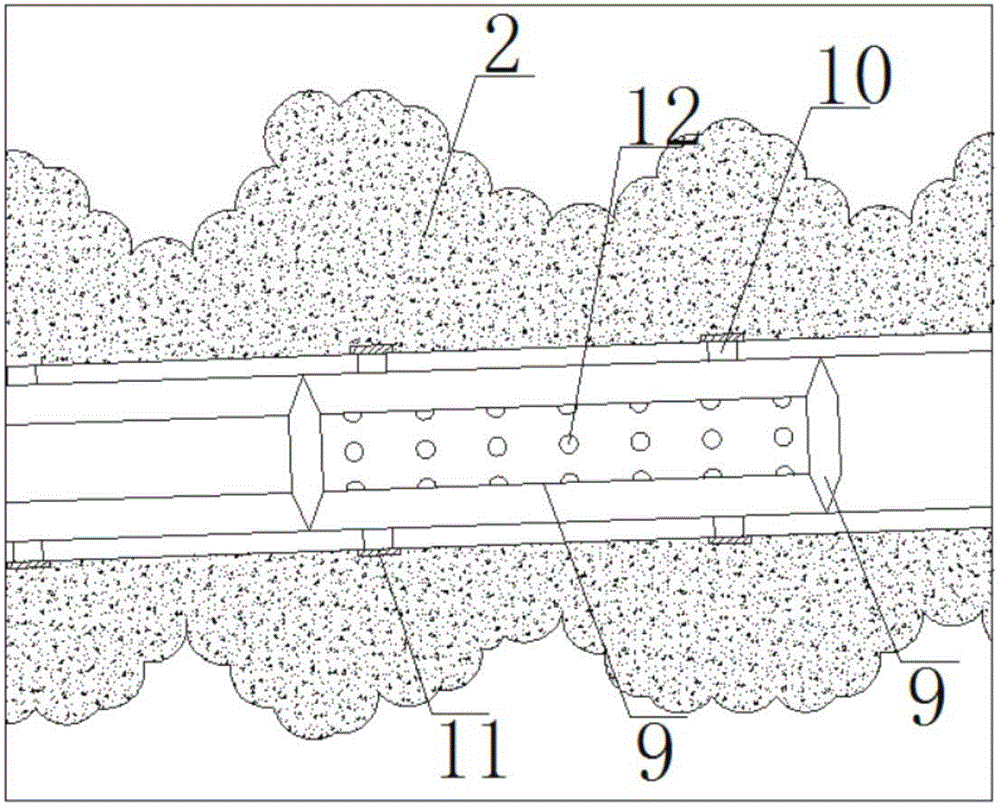

[0057] The steel sleeve valve pipe 3 includes a grouting pipe 9 and an outer pipe. The outer pipe of the steel sleeve valve pipe 3 has several drainage holes 4 and grouting holes 10 . The area with drainage holes 4 is close to the tail of the steel sleeve valve pipe 3 , and the area with grouting holes 10 is close to the head of the steel sleeve valve pipe 3 . The orifice of the grouting hole 10 has a rubber sleeve 11 .

[0058] The inner and outer walls of the outer tube of the steel sleeve valve tube 3 are covered with an epoxy resin protective la...

Embodiment 2

[0076] A construction method of a sleeve valve pipe grouting drainage soil nail support device, comprising the following steps:

[0077] 1) Investigate and analyze the geological conditions of the slope, conduct engineering geological exploration and design, analyze and determine the design length and diameter of soil nails.

[0078] 2) According to the design length and diameter, make the steel sleeve valve tube 3 in advance:

[0079] The steel sleeve valve pipe 3 includes a grouting pipe 9 and an outer pipe. The outer pipe of the steel sleeve valve pipe 3 has several drainage holes 4 and grouting holes 10 . The area with drainage holes 4 is close to the tail of the steel sleeve valve pipe 3 , and the area with grouting holes 10 is close to the head of the steel sleeve valve pipe 3 . The orifice of the grouting hole 10 has a rubber sleeve 11 .

[0080] The inner and outer walls of the outer tube of the steel sleeve valve tube 3 are covered with an epoxy resin protective la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com