Air pressure transmitting type magneto-rheological damper

A magnetorheological damper and damper technology, applied in the field of dampers, can solve the problems of expensive magnetorheological fluid, a large amount of magnetorheological fluid, leakage of magnetorheological fluid, etc., and achieve good adjustability and applicability High performance, strong anti-leakage ability, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

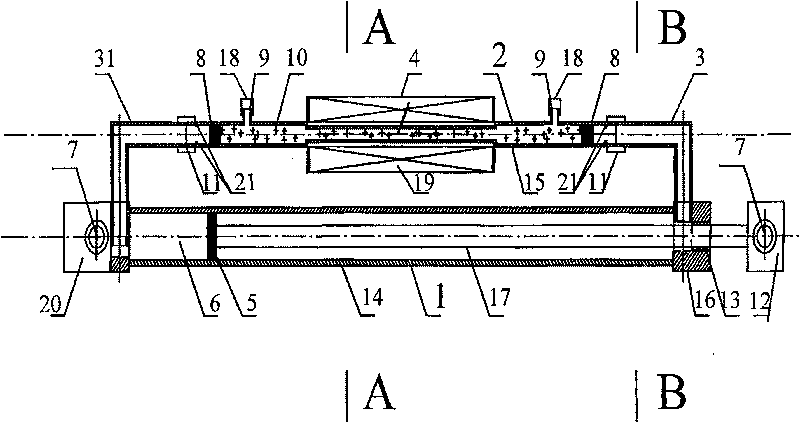

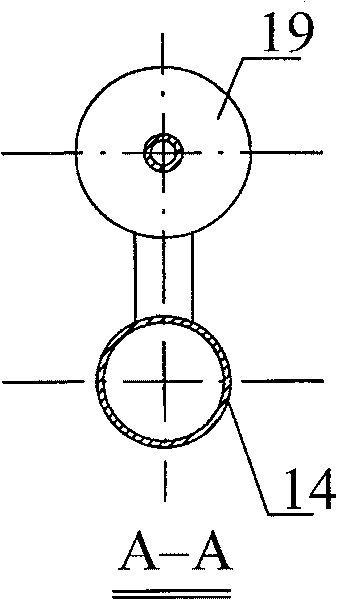

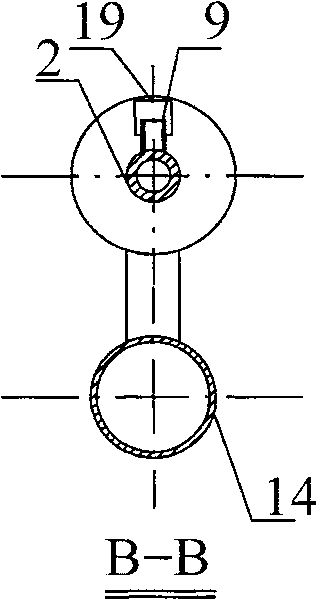

[0018] The air transmission pressure magnetorheological damper of the present invention is composed of a main part 1 and an accessory part 2 . The main part is mainly composed of the main part outer cylinder 14, the main part piston 5, the main part piston rod 17, the cylinder block 6, the right sealing sleeve 16, the left sealing sleeve 20, etc. The accessory 2 consists of the left elbow 31 and the right elbow 3. Piston 8, a damping pipe 4 with variable gap, liquid injection port 9, magnetorheological fluid 10, threaded sleeve 11, stopper 21, accessory outer cylinder 15, nut 18, electromagnetic coil 19 and other parts. There is a threaded hole on the right sealing sleeve 16 to connect with the elbow 3 of the accessory 2, the main part piston rod 17 passes through the right sealing sleeve 16 and is connected to the connecting plate 12 with the bolt hole 7 in the middle, at the main part piston rod 17 There is a rubber sealing ring 13 between it and the right sealing sleeve 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com