Constructional column top pouring construction method

A construction method and technology for constructing columns, which are applied in building construction, building material processing, construction, etc., can solve the problems of technology, operating condition limitations, reducing seismic effect, and difficulty in ensuring the pouring of top concrete, and achieving a simple production process. , The effect of improving construction quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

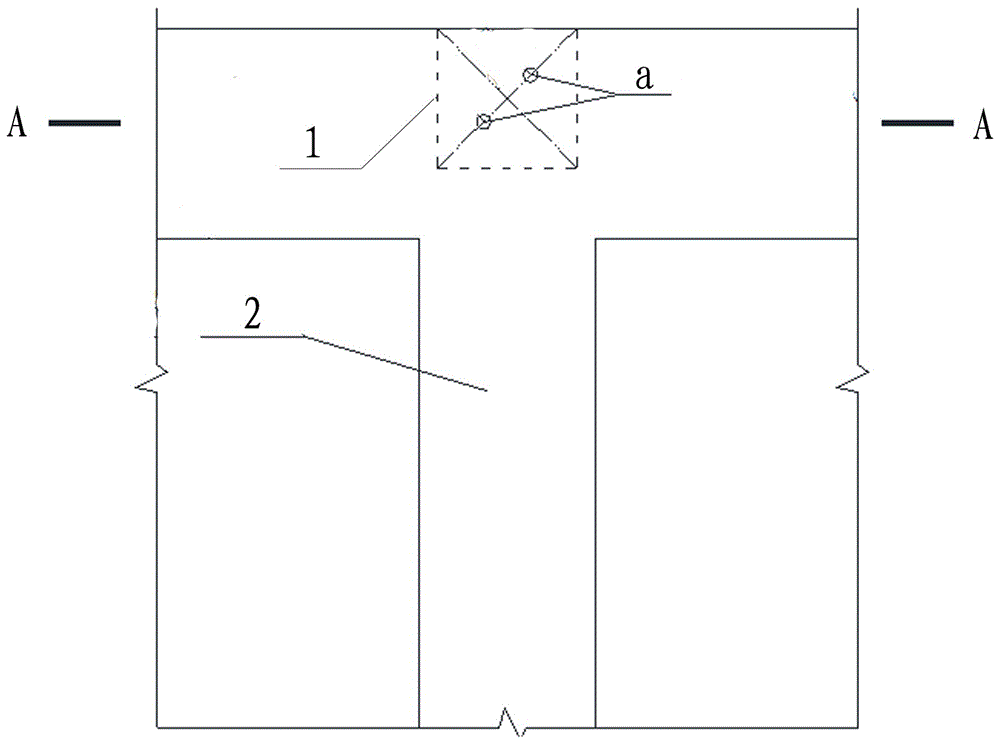

[0020] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

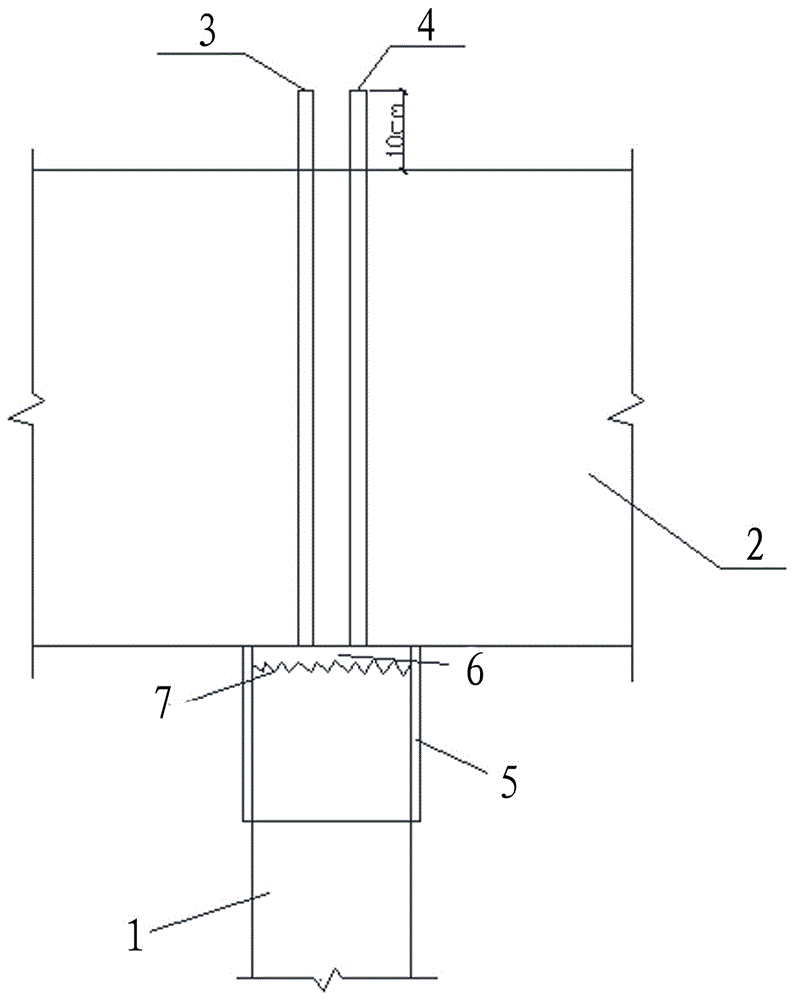

[0021] The process principle of the present invention is that the concrete beam slab steel bars and formwork are installed and before the concrete is poured. Use the painting positioning marking tool to paint and position with red paint on the bottom mold at the diagonal position of the construction column plane. Then fix the two galvanized steel pipes whose ends are blocked with adhesive tape at the location of the red paint, and bind and fix them with the steel bars inside the beams and reserve them. After the concrete pouring of the beam and slab is completed and the formwork is removed, insert the pre-embedded galvanized steel pipe through the upper part of the structural column with a sharp steel rod.

[0022] The concrete of the structural column of the infill wall is poured to the bottom of the beam, and when it cannot be compacted, the top formwork...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com