Small-displacement energy recovering cylinder

An energy recovery, small displacement technology, applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of low energy collection and utilization, dissipation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

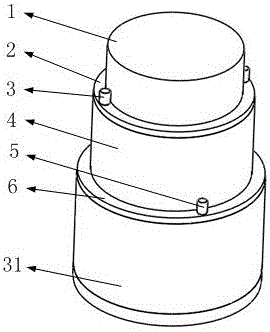

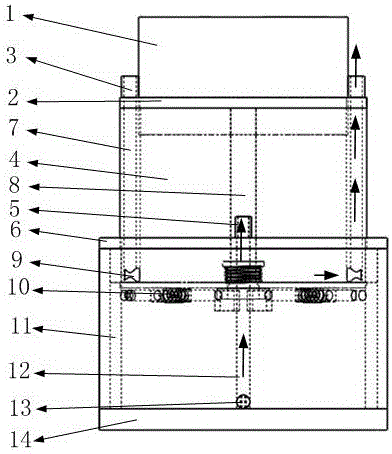

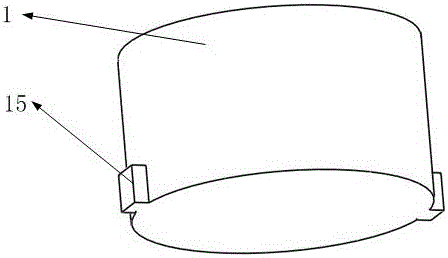

[0025] Such as figure 1 As shown, it includes a first air plug 1, a first stop ring 2, a second air inlet and outlet pipe 3, a second cylinder 4, a third air inlet and outlet pipe 5, a second stop ring 6, a second air inlet and outlet passage 7, a second air inlet and outlet pipe A guide groove 8, a second air inlet and outlet hole 9, a locking mechanism 10, a second guide groove 11, a third air inlet and outlet channel 12, a third air inlet and outlet hole 13, a third bottom plate 14, a first guide block 15, and a second guide block 16. Threaded hole 17, second bottom plate 18, clamping hole 30, third cylinder 31, wherein such as Figure 9 As shown, the bottom end of the third cylinder 31 is equipped with a third bottom plate 14, as Figure 8 As shown, the top is equipped with a second limit ring 6, and two third air inlet and outlet pipes 5 are symmetrically installed on the second limit ring 6; as Image 6 As shown, the bottom of the second cylinder 4 is equipped with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com