Buffer

A buffer and elastic body technology, applied in the field of non-hydraulic, non-pneumatic, and non-hydraulic buffers, can solve the problems of high machining accuracy, complex design of hydraulic buffers, and high requirements for accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

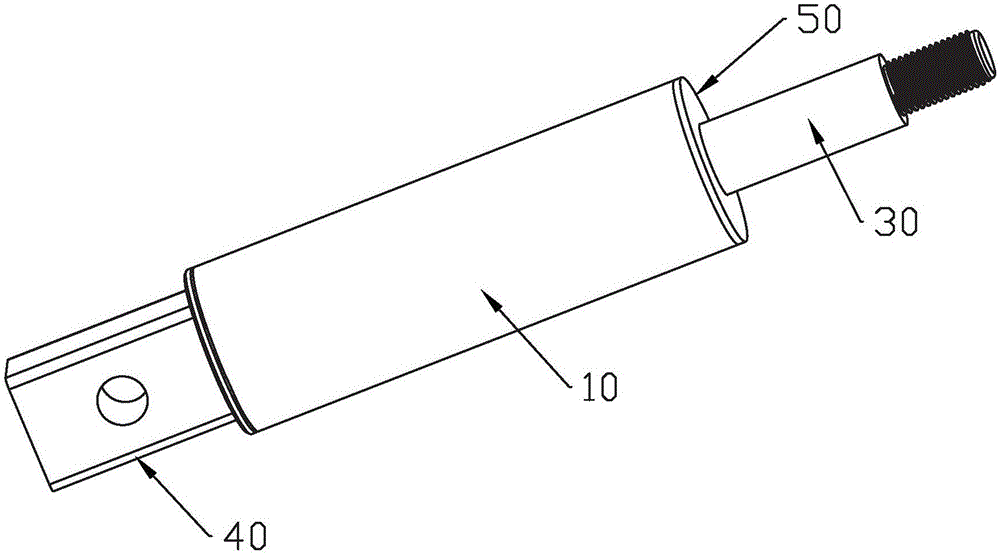

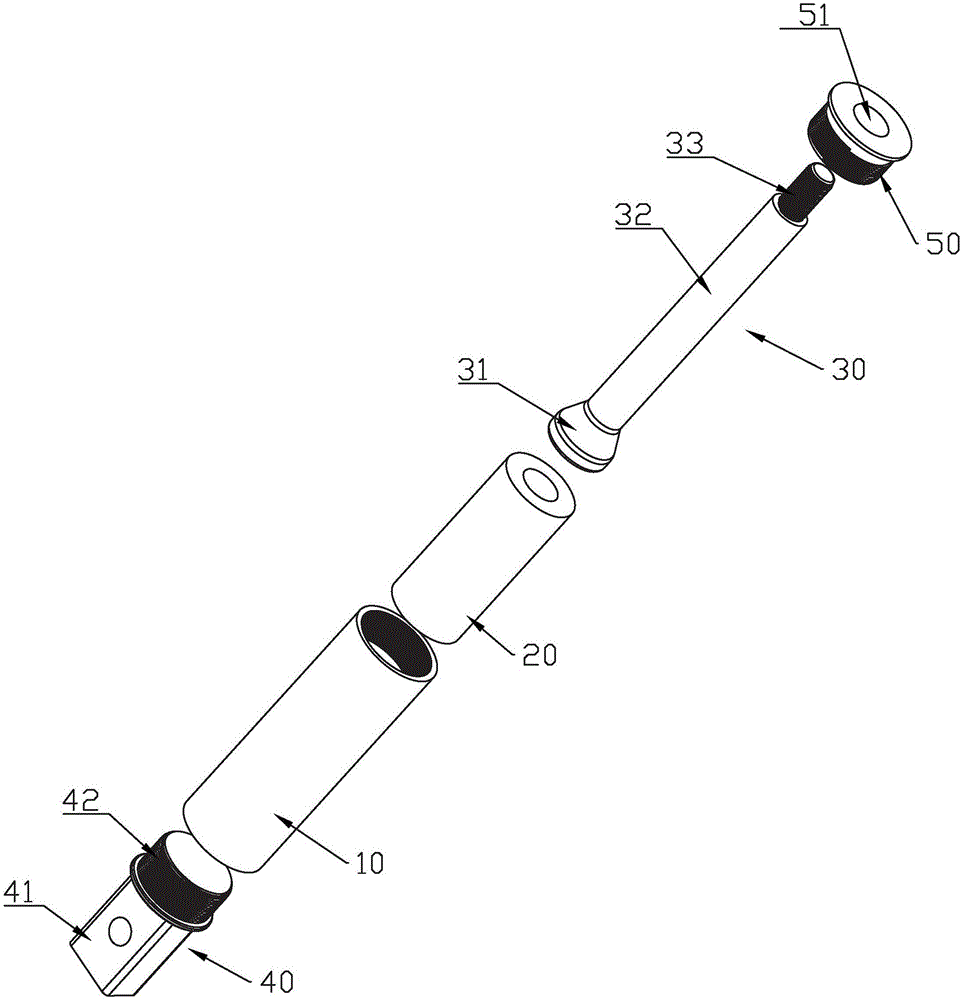

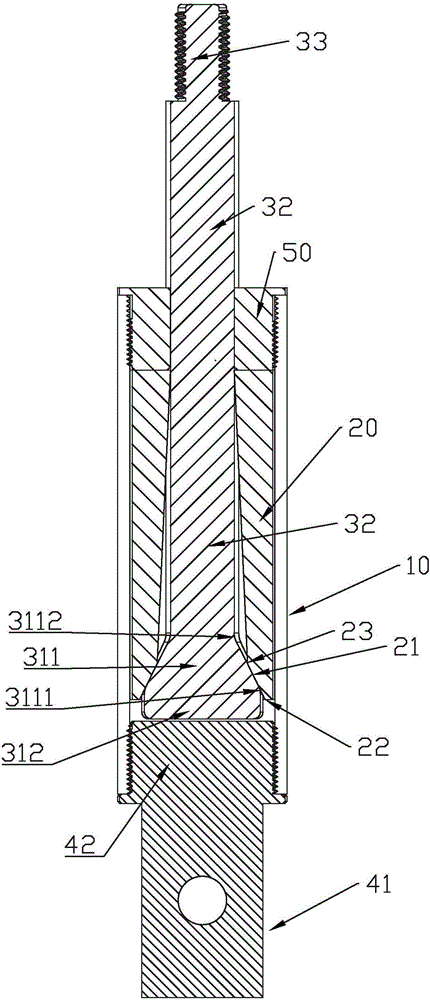

[0033] Such as Figure 1 to Figure 8 As shown, the buffer 1 of the present invention includes an outer shell 10 , an elastic body 20 , a movable shaft 30 , and a connecting piece 40 . Further, it may also include an end cap 50 .

[0034] Such as Figure 1 ~ Figure 3 As shown, the outer casing 10 is cylindrical, and in this embodiment, it is cylindrical. The outer casing 10 can be configured to be open at both ends, or can be configured to be open at one end, so that it can be inserted into the elastic body 20 .

[0035] Such as Figure 2 ~ Figure 3As shown, the elastic body 20 is used for cushioning, and it is cylindrical, and its shape is the same or similar to that of the outer casing 10 , and in this embodiment, it is cylindrical. Both ends of the elastic body 20 are open, and are used for movably setting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com