Improved structure of heat exchanger baffle plate

A baffle and heat exchanger technology, applied in the field of heat exchange technology, can solve the problems of reducing heat transfer efficiency, three-dimensional fin impact, heat transfer tube vibration, etc., to increase heat transfer coefficient, reduce impact, increase The effect of large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

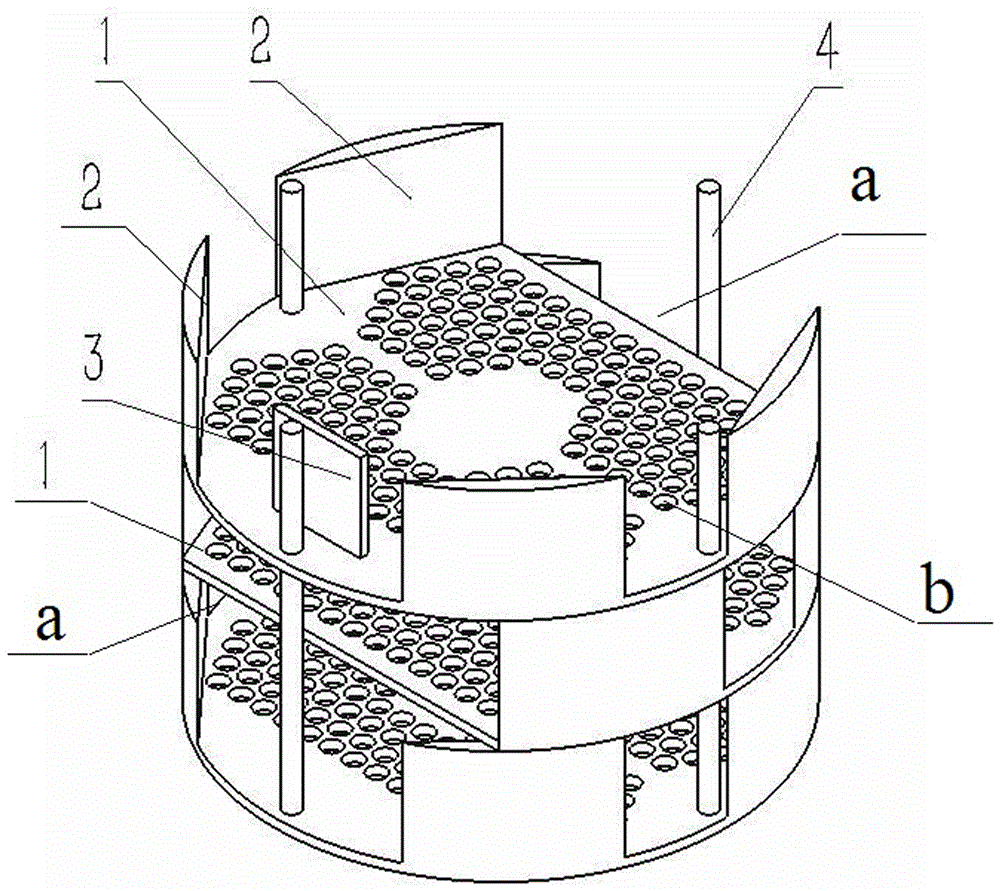

[0021] As shown in the figure, the present invention includes several baffle bodies 1 with guide gaps a arranged in the heat exchanger shell, and heat transfer tubes arranged on the baffle body 1 for piercing the heat transfer tubes. Tube hole b, the gaps a on the two adjacent baffle bodies 1 are staggered to form an S-shaped fluid channel in the heat exchanger shell. The special feature is that the edges of the baffle body 1 on both sides of the gap a A deflector 2 is provided, and an inlet baffle 3 is provided on the edge of the deflector body 1 facing the notch a.

[0022] The baffle body 1 is a single-bow baffle, on which there are four positioning rod holes for installing the positioning rod 4 and a series of heat transfer tube holes b, and the heat transfer tube holes b are arranged symmetrically in a butterfly shape. And there is no heat transfer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com