Test method of acoustic vibration transfer function of suspension absorber vehicle body attaching points

A transfer function and shock absorber technology, which is applied in the field of acoustic-vibration transfer function test of the attachment point of the suspension shock absorber body, and can solve problems such as differences in test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

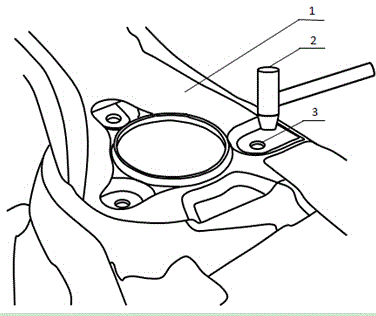

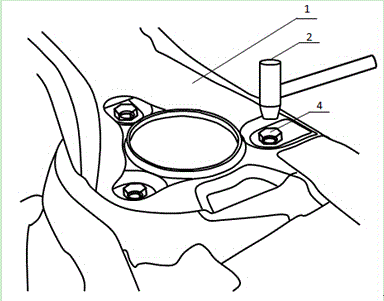

[0029] The test device for the acoustic-vibration transfer function of the attachment point of the suspension shock absorber body includes: a suspension shock absorber 1, a force hammer 2, a microphone, a data acquisition front end, a processing device and a tooling part 5.

[0030] Test preparation: The state of the prototype car is the state of the interior and body, make sure the doors and sunroof are closed.

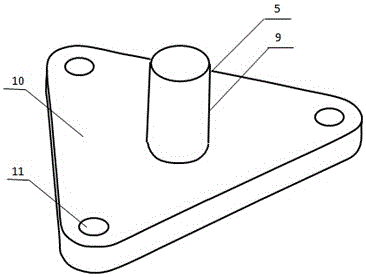

[0031] Such as image 3 As shown, the tooling part 5 includes: a base 10, a boss 9, and a base through hole 11; the base 10 is an equilateral triangle with rounded corners, a cylindrical boss 9 is welded in the center, and a base through hole is distributed at each of the three corners. 11. The position and size of the base through hole 11 is matched with the installation through hole 3 of the suspension shock absorber. The material of the tooling parts is aluminum, the thickness of the base 10 is 12.7 mm, the diameter of the cylindrical boss 9 is 25 mm, the height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com