Heat Generating Unit, Fixing Unit And Image Forming Apparatus

A technology of heating unit and heating element, which is applied in the fields of electric recording technology using charge pattern, equipment for electric recording technology using charge pattern, electric recording technique, etc. It can solve the problem of fast response to overheating of the heater and the heat capacity of PTC resistors. Increase and other problems, achieve high reliability, suppress overheating, and suppress local overheating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings.

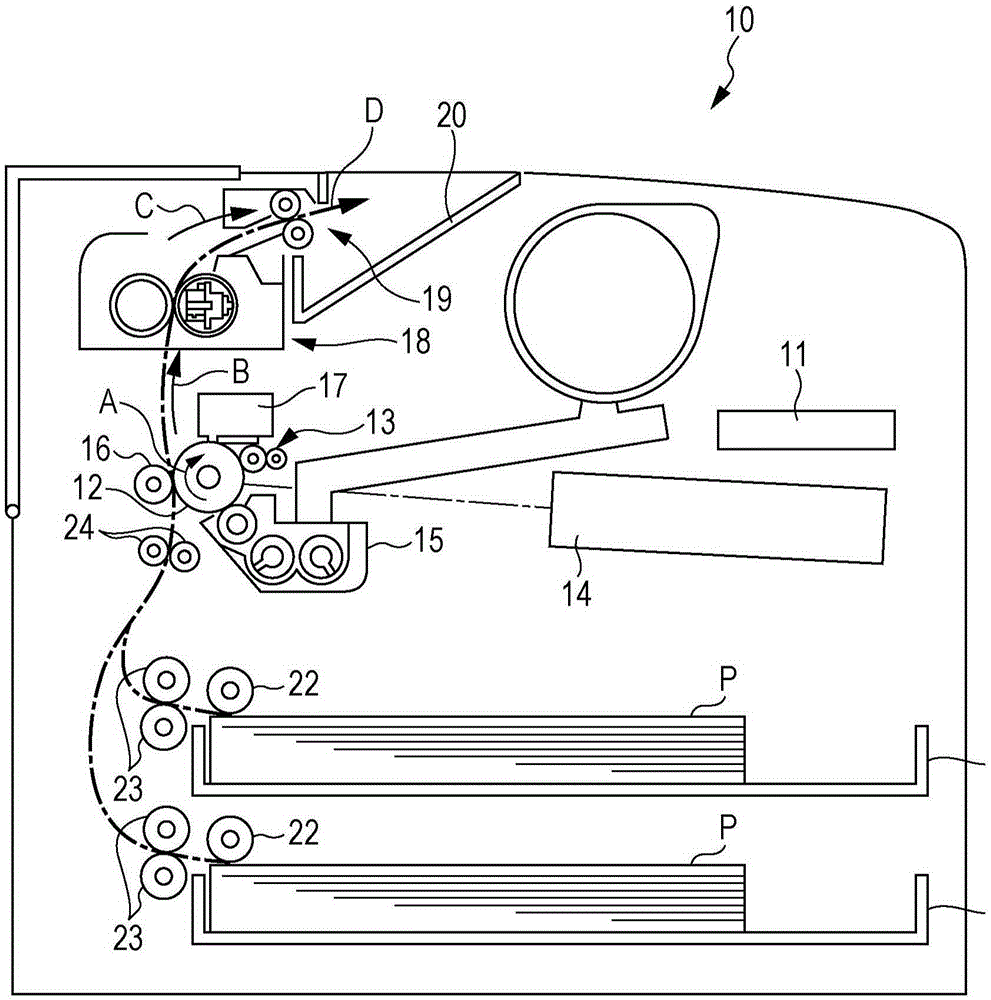

[0022] figure 1 is a schematic diagram showing the configuration of a printer serving as an exemplary embodiment of the image forming apparatus of the present invention.

[0023] exist figure 1 The printer 10 shown in is a monochrome printer. An image signal representing an image generated outside the printer 10 is input to the printer 10 via a signal cable or the like (not shown). The printer 10 includes a controller 11 that controls operations of elements inside the printer 10 and into which the image signal is input. In the printer 10 , under the control of the controller 11 , image formation based on the image signal is performed.

[0024] A sheet tray 21 is provided at the bottom of the printer 10 . The sheet trays 21 each accommodate a stack of sheets P. The sheet tray 21 is configured such that the sheet tray 21 can be freely drawn out for suppl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap