Induction heating unit, fixing apparatus, and image forming apparatus

A technology of electromagnetic induction heating and thermal fixing, which is applied in the fields of fixing devices, image forming devices, and induction heating units, and can solve the problems of overheating acceleration and cost increase in non-paper-feeding areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following and other aspects, features and advantages of the present invention can be more clearly illustrated in conjunction with the following drawings describing specific embodiments of the present invention.

[0040] Next, embodiments of the induction heating unit, the fixing device, and the image forming apparatus of the present invention will be described with reference to the drawings.

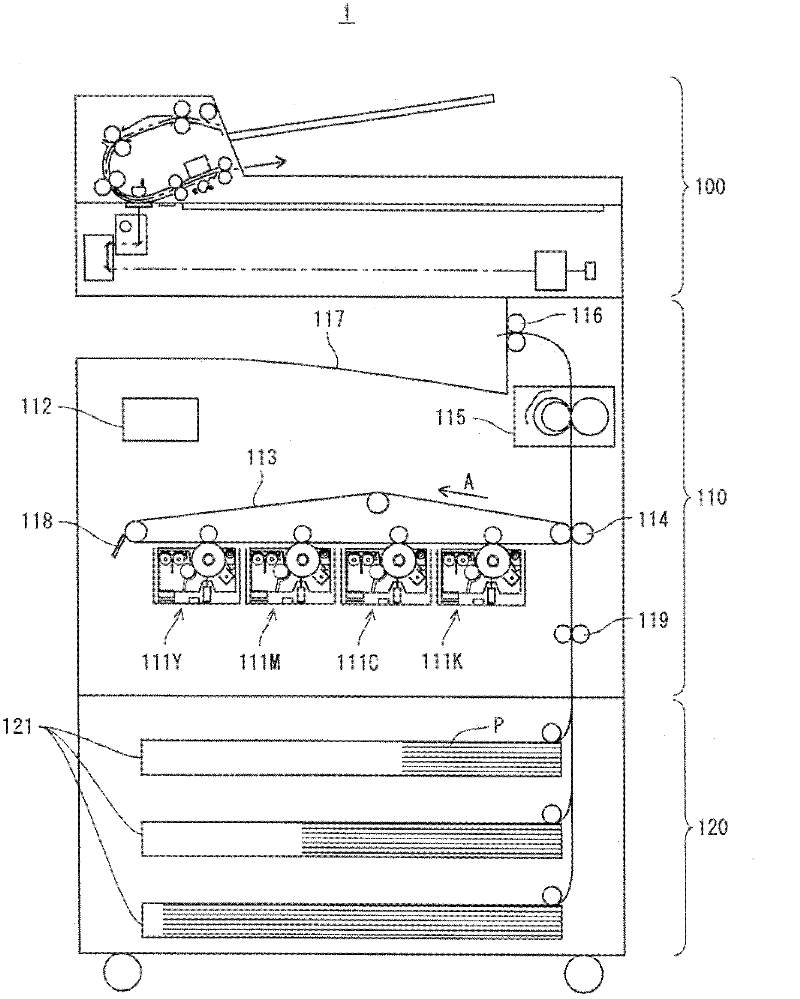

[0041] [1] Structure of image forming apparatus

[0042] First, the configuration of the image forming apparatus of this embodiment will be described.

[0043] figure 1 is the main structure of the image forming apparatus showing the embodiment of the present invention. Such as figure 1 As shown, the image forming apparatus 1 includes: a document reading unit 100 , an image forming unit 110 , and a paper feeding unit 120 . The document reading unit 100 optically reads a document placed on a document table tray by an automatic document feeder (ADF: Automatic Document Feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com