Master-slave burners for stove

A main burner and burner technology, applied in the direction of burners, gas fuel burners, and the combination of multiple burners, can solve problems such as durability deterioration, and achieve the purpose of preventing durability deterioration, suppressing overheating, Improve the effect of heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

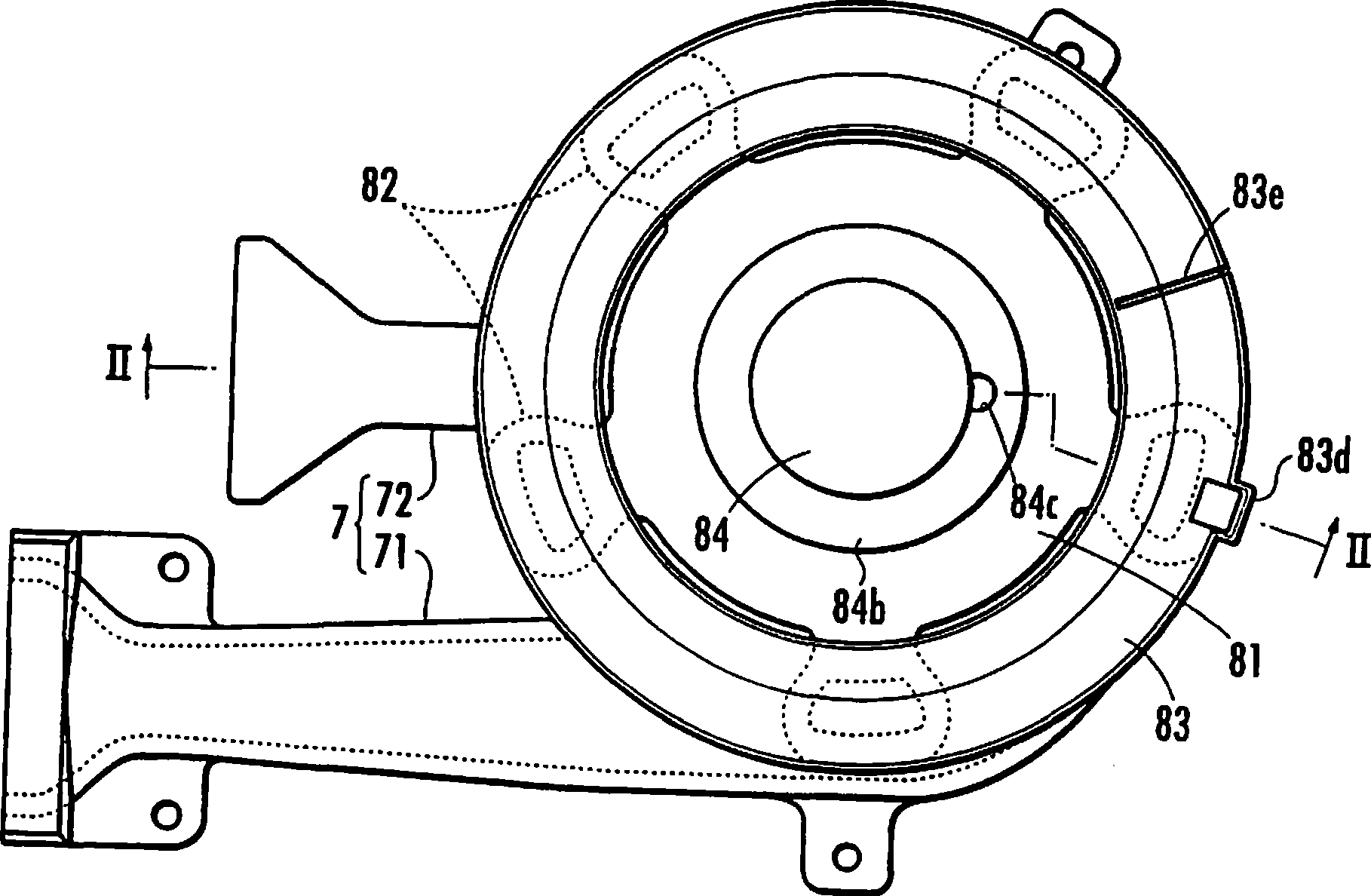

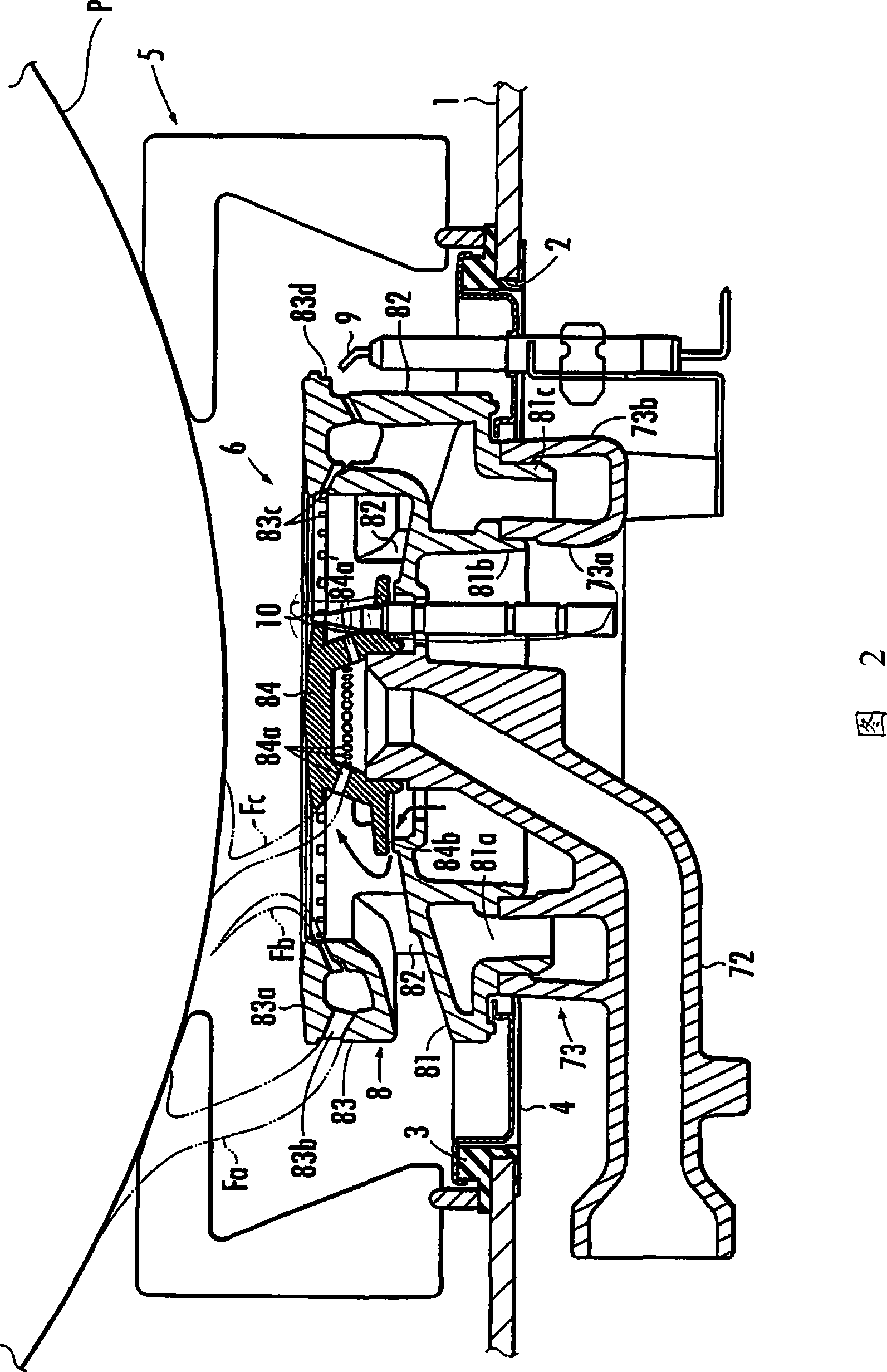

[0013] The embodiment of the present invention will be described with reference to FIG. 2. Reference numeral 1 is a top plate covering the upper surface of the stove main body, which is not shown in the figure. The top plate 1 is provided with an opening 2 for burners facing the main and auxiliary burners 6 of the embodiment of the present invention provided on the main body of the furnace. The top plate 1 is formed of a thick plate made of metal such as aluminum or a glass plate, and a gasket 3 is attached to the peripheral edge of the burner opening 2. In addition, the flame holder 5 and the annular juice tray 4 projecting into the burner opening 2 are placed on the gasket 3.

[0014] Such as figure 1 As shown in FIG. 2, the main and auxiliary combustor 6 includes a mixing tube unit 7 and a combustor main body 8. The mixing tube unit 7 has a first mixing tube 71 and a second mixing tube 72. At the downstream end of the first mixing pipe 71, a dispersion chamber portion 73 having...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com